Phosphate-base red luminescent material and preparation method thereof

A technology of red luminescence and phosphate, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of limited vacuum ultraviolet light absorption capacity and low external quantum efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] See Figure 4 To illustrate the flow of the preparation method of the phosphate-based red luminescent material of the embodiment of the present invention, the preparation method includes the following steps:

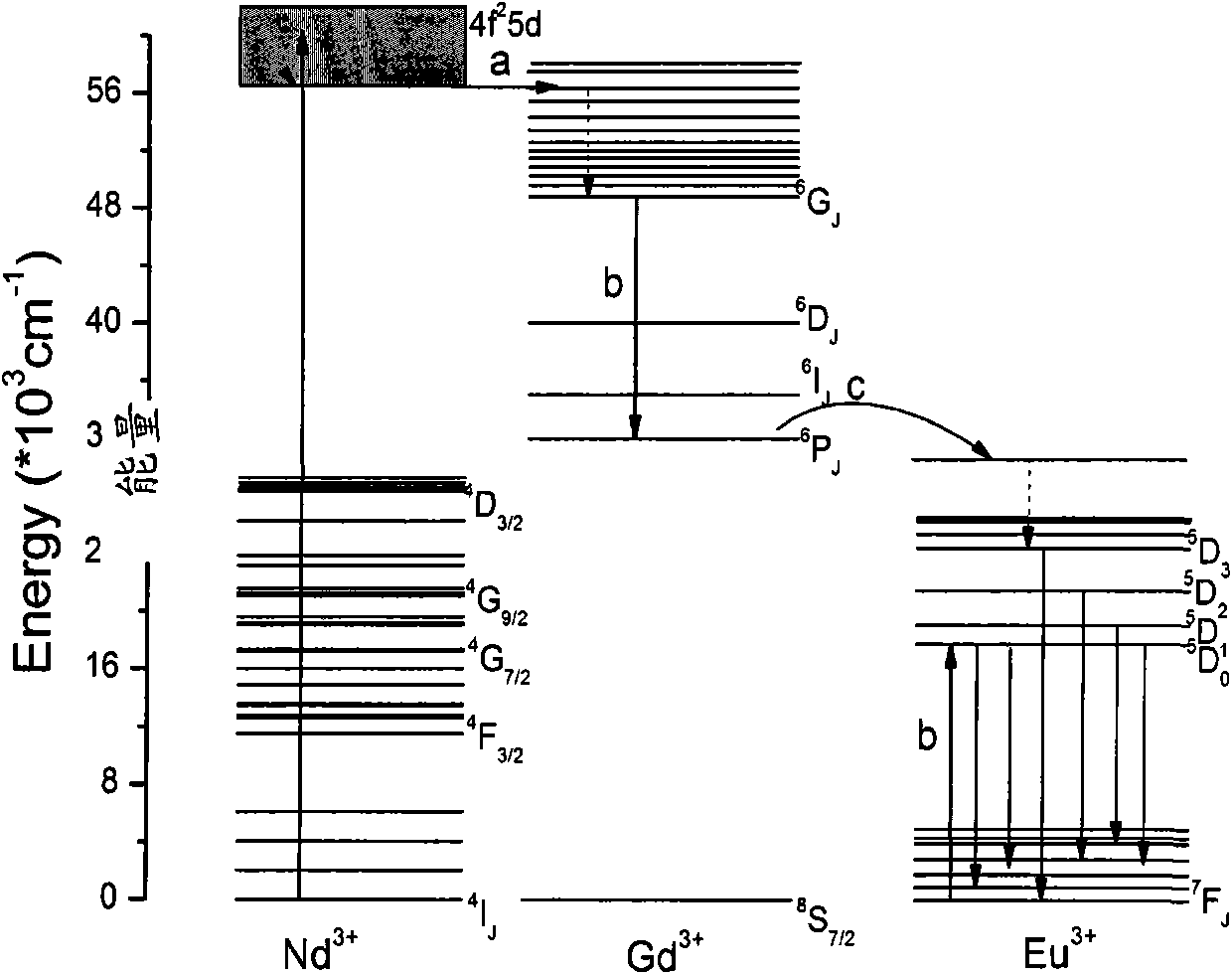

[0028] S01: Select the source compound of alkaline earth metal ion, the source compound of rare earth ion and Nd according to the stoichiometric ratio 3+ , Gd 3+ And Eu 3+ The stoichiometric ratio of the source compound is in accordance with the structural formula M 3 Re 1-x-y-z Nd x Gd y Eu z (PO 4 ) 3 The molar ratio of the corresponding element in the phosphate ion, wherein the molar ratio of the source compound of phosphate ion is 10%-30%, M is alkaline earth metal element, Re is rare earth element, x=0.005-0.1, y=0.005-0.3, z =0.02-0.5;

[0029] S02: Mix the source compounds;

[0030] S03: Pre-treat the mixture for sintering and then cool it;

[0031] S04: Take out the sintered product for grinding, then calcinate the ground product, and obtain the phosphate-based ...

Embodiment 1

[0038] Weigh strontium carbonate SrCO 3 1.4763g, ammonium dihydrogen phosphate NH 4 H 2 PO 4 1.4954g (the molar ratio is over 30%, the following examples are basically the same and will not be repeated), gadolinium oxide Gd 2 O 3 0.5317g, neodymium oxide Nd 2 O 3 0.0112g, europium oxide Eu 2 O 3 0.0587g, boric acid H 3 BO 3 After 0.0052g is fully ground in an agate mortar, it is placed in a corundum crucible and pre-fired at 600°C for 2h, then cooled to room temperature, and taken out to be fully ground again. Finally, calcinate it at 1200 for 5h, cool it, take it out and grind it to get Sr 3 Nd 0.02 Gd 0.88 Eu 0.10 (PO 4 ) 3 Phosphate-based red luminescent material.

Embodiment 2

[0040] Weigh barium carbonate BaCO 3 1.9733g, ammonium dihydrogen phosphate NH 4 H 2 PO 4 1.4954g, gadolinium oxide Gd 2 O 3 0.5679g, neodymium oxide Nd 2 O 3 0.0056g, europium oxide Eu 2 O 3 0.0294g, barium fluoride BaF 2 After 0.0058g is fully ground in an agate mortar, it is placed in a corundum crucible and pre-fired at 600°C for 2h, then cooled to room temperature, and taken out to be fully ground again. Finally, calcinate it at 1200℃ for 5h, cool it, take it out and grind it to get Ba 3 Gd 0.94 Nd 0.01 Eu 0.05 (PO 4 ) 3 Phosphate-based red luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com