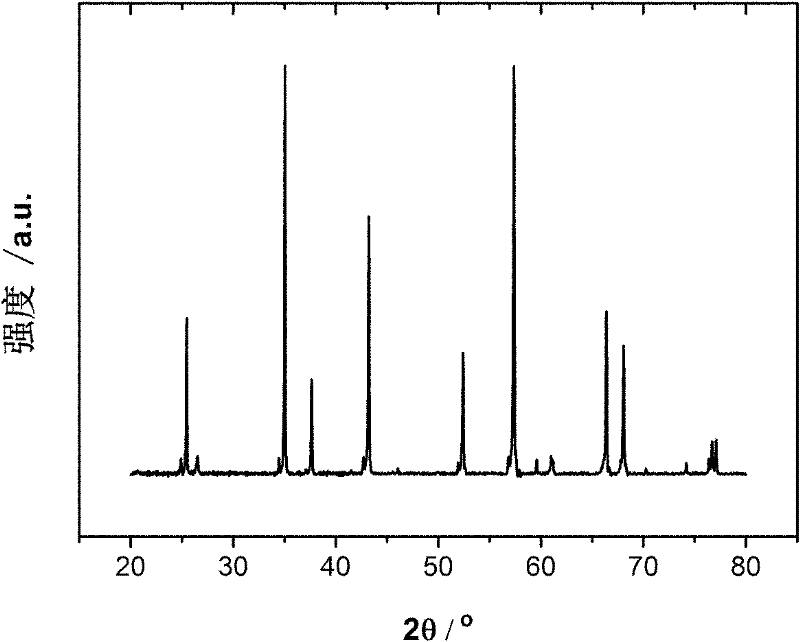

Crucibleless growth method of sapphire crystals in different atmospheres

A sapphire crystal, crucible-free technology, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., to achieve the effects of simple operation of growth equipment, low energy consumption, and elimination of potential pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Ingredients and bar preparation: the high-purity raw material Al 2 o 3 , FeTiO 3 and Fe 2 o 3 , according to mass percentage 98.6%wtAl 2 o 3 +0.8%wtFe 2 o 3 +0.6wt% FeTiO 3 Mixing, and then mechanical mixing; after drying, put the mixture into rubber balloons and place it under isostatic pressure to make green bars. Put it into a high-temperature sintering furnace with a sintering temperature of 1350°C and a sintering time of 6 hours to obtain a polycrystalline rod;

[0029] (2) Fixing of the material rod and its seed crystal: the polycrystalline rod is put into the crystal growth furnace, the material rod is fixed on the upper part of the central axis of crystal growth, the polycrystalline rod seed crystal is fixed on the lower part of the crystal growth central axis, and then Cover the quartz tube to prevent external gas from entering;

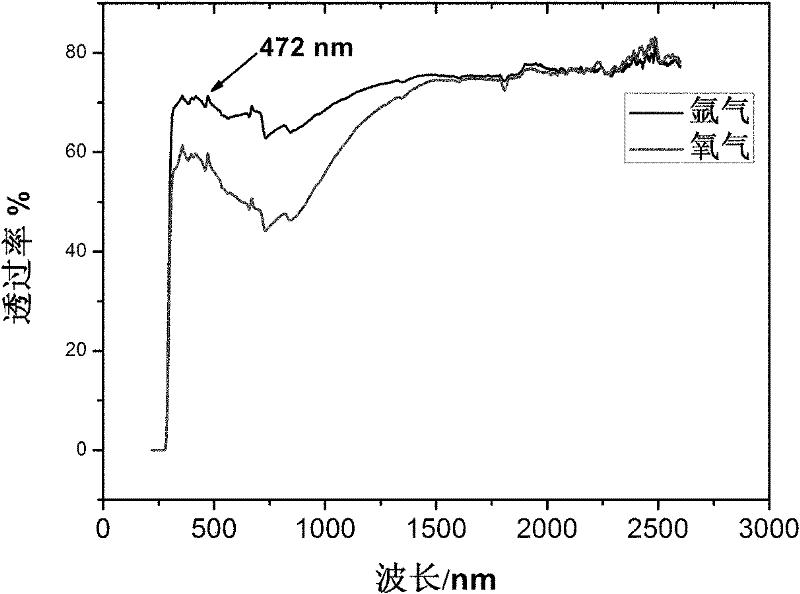

[0030] (3) Atmosphere introduction: pass the oxygen atmosphere required for crystal growth into the quartz tube, adjus...

Embodiment 2

[0035] (1) Ingredients and bar preparation: the high-purity raw material Al 2 o 3 , FeTiO 3 and Fe 2 o 3 , according to mass percentage 98.6%wtAl 2 o 3 +0.8%wtFe 2 o 3 +0.6wt% FeTiO 3 Mixing, and then mechanical mixing; after drying, put the mixture into rubber balloons and place it under isostatic pressure to make green bars. Put it into a high-temperature sintering furnace with a sintering temperature of 1450°C and a sintering time of 10 hours to obtain a polycrystalline rod;

[0036] (2) Fixing of the material rod and its seed crystal: the polycrystalline rod is put into the crystal growth furnace, the material rod is fixed on the upper part of the central axis of crystal growth, the polycrystalline rod seed crystal is fixed on the lower part of the crystal growth central axis, and then Cover the quartz tube to prevent external gas from entering;

[0037] (3) Atmosphere introduction: Introduce the argon atmosphere required for crystal growth into the quartz tube, ...

Embodiment 3

[0042] (1) Ingredients and bar preparation: the high-purity raw material Al 2 o 3 , FeTiO 3 and Fe 2 o 3 , according to mass percentage 98.6%wtAl 2 o 3 +0.6%wtFe 2 o 3 +0.8wt% FeTiO 3 Mixing, and then mechanical mixing; after drying, put the mixture into rubber balloons and place it under isostatic pressure to make green bars. Put it into a high-temperature sintering furnace with a sintering temperature of 1550°C and a sintering time of 12 hours to obtain a polycrystalline rod;

[0043] (2) Fixing of the material rod and its seed crystal: the polycrystalline rod is put into the crystal growth furnace, the material rod is fixed on the upper part of the central axis of crystal growth, the polycrystalline rod seed crystal is fixed on the lower part of the crystal growth central axis, and then Cover the quartz tube to prevent external gas from entering;

[0044] (3) Atmosphere introduction: pass the oxygen atmosphere required for crystal growth into the quartz tube, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com