Preparation method of vanadium dioxide powder

A technology of vanadium dioxide and powder, which is applied in the field of vanadium dioxide powder preparation by hydrothermal method, can solve the problems of slow research progress, difficulty in preparation, and does not cause scientific research workers, and achieves good crystallinity of the product, easy operation, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of the vanadium dioxide powder of the present invention can use a tetravalent vanadium ion aqueous solution as a reaction precursor, and treat the reaction precursor with an alkaline reagent.

[0031] The configuration of the tetravalent vanadium ion aqueous solution can be prepared by a method commonly used in this field: dissolve the tetravalent soluble vanadium raw material in an appropriate amount of water, preferably deionized water, and the suitable concentration can be 0.005-0.5mol / L, usually 0.01 mol / L L. Quaternary soluble vanadium salts can be commonly used cheap vanadium salts, such as vanadyl sulfate (VOSO 4 ) and vanadium oxychloride (VOCl 2 ). Of course, hydrates of vanadium salts, such as vanadyl oxalate anhydrate (VOC 2 o 4 .5H 2 o). The preparation of the tetravalent vanadium ion solution is usually carried out at normal temperature, but it is also understandable that a little heating or ultrasonication can be used to assist the di...

Embodiment 1

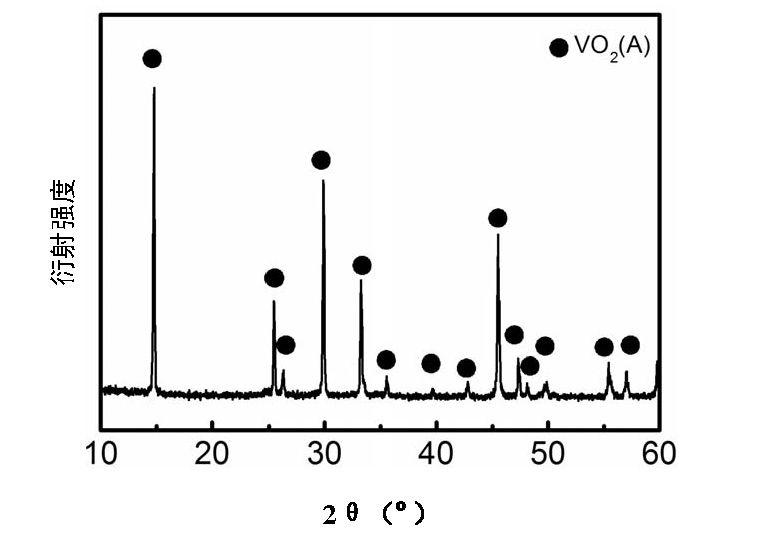

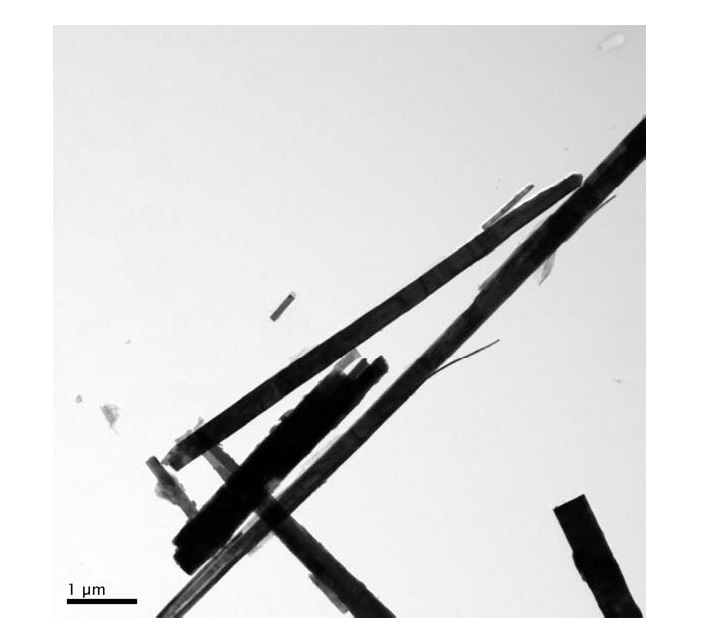

[0044] 1g VOSO 4 Dissolve the powder in 50ml deionized water, titrate with 1 mol / L NaOH solution, and keep stirring. After the titration is complete, put the suspension into a 50ml hydrothermal kettle filled with 45ml deionized water, and heat it at 250℃. Reaction for 12 hours, centrifugal drying to obtain vanadium dioxide powder, its chemical formula is VO 2 , the yield is 90%. like figure 1 Its crystal phase is A phase shown in the XRD spectrum, as figure 2 As shown in the TEM photo, the obtained vanadium dioxide powder is in the shape of a long rod, and each long rod of vanadium dioxide is a single crystal, with a length of hundreds of nm to tens of μm and a width of several hundreds of nm.

Embodiment 2

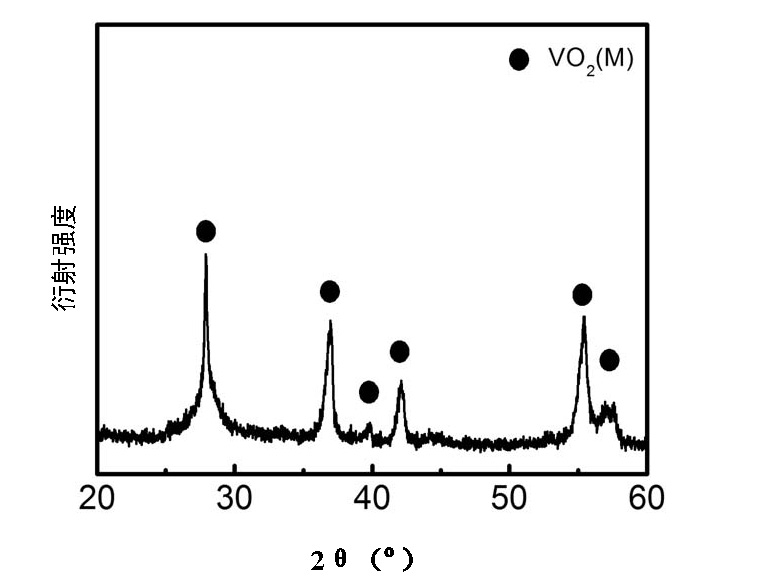

[0046] 1g VOSO 4 Dissolve the powder in 50ml deionized water, titrate with 1 mol / L NaOH solution, and keep stirring, and mix the suspension with 25mg Bi 2 o 3 Put them together into a 50ml hydrothermal kettle filled with 45ml deionized water, conduct a hydrothermal reaction at 250°C for 12 hours, and centrifuge and dry to obtain vanadium dioxide powder. After elemental analysis, its chemical formula is V 0.983 Bi 0.017 o 2 , the yield is 90%. like image 3 Its crystal phase is M phase as shown in the XRD spectrum, as Figure 4 As shown in the TEM photo, the prepared vanadium dioxide powder is granular, and each vanadium dioxide particle is a single crystal particle, and its grain size is mainly concentrated between 40-70nm, and the aspect ratio is less than 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com