Method for isomerizing alpha-pinene

A technology for isomerization and pinene, which is applied in isomerization to hydrocarbon production, organic chemistry, etc., can solve problems such as environmental pollution and complicated product post-processing, and achieve the effects of high reaction activity, short time consumption and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 10 ml granular (diameter ≤ 2 mm) high-purity γ-Al 2 o 3 Put it into the glass material fixed bed reaction tube I, in the high-purity N 2 (purity ≥ 99.99%, flow rate 20 -100ml / min) in the atmosphere at 500 o C pretreatment for 2 hours, after that, feed CCl simultaneously at a flow rate of 0.8-2.00 ml / h 4 (pre-dried to remove water), in-situ generation of AlCl 3 ; 5ml of 40-60 mesh mesoporous SiO2 was loaded into the fixed bed reaction tube II 2 , at high purity N 2 300 in airflow (40 ml / min) o After C pretreatment for 2 h, the reaction tube I was connected to the reaction tube II, and the 2 In situ generation of AlCl under gas flow 3 with SiO 2 Reaction of surface hydroxyl groups with AlCl 3 fixed load. After 2-3h, stop feeding CCl 4 , at 300 o Continue to use N under C 2 Purge for 1 h, under N 2 Cool to room temperature under protection for later use. The catalyst is denoted as AlCl 3 / SiO 2 .

Embodiment 2

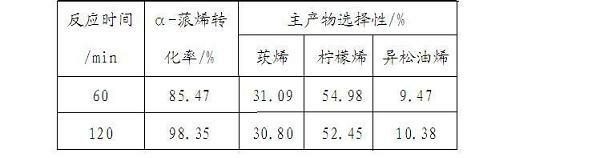

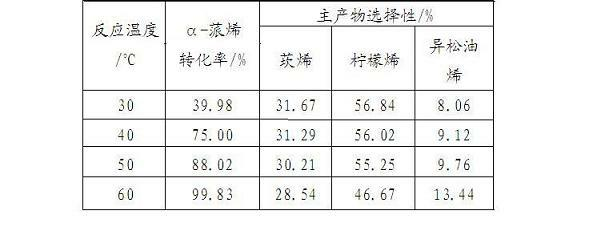

[0021]

[0022] Table 2

Embodiment 3

[0024] According to the preparation method of the catalyst in Example 1, the support is changed to double-hole γ-Al 2 o 3 . Carrier in high purity N 2 400 in airflow o After C pretreatment for 2 h, in N 2 Cool down to 300 in airflow o C, with in situ generated AlCl 3 Reaction 3 h, N 2 Warm up to 400 in airflow o C was purged for 1 h, cooled to room temperature for later use, and the obtained catalyst was denoted as AlCl 3 / γ-Al 2 o 3 .

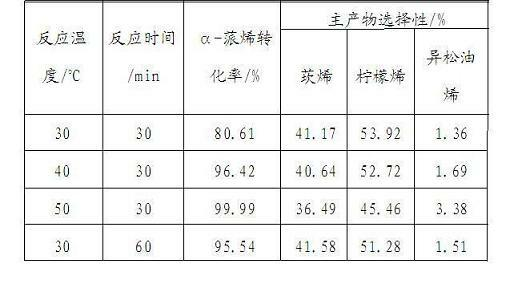

[0025] Use this catalyst to catalyze the isomerization of α-pinene: add magneton, 2 ml α-pinene, 0.2 ml n-decane (internal standard) and 0.1 g AlCl in a dry reaction tube 3 / γ-Al 2 o 3 catalyst. The results at different reaction temperatures and reaction times are shown in Table 3: AlCl 3 / γ-Al 2 o 3 Catalyzed α-pinene isomerization reaction results.

[0026]

[0027] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com