Method for testing lead content in copper by inductively coupled plasma emission spectrometry

A plasma and inductive coupling technology, applied in the field of testing and analysis, can solve the problem of not measuring the lead content in copper, and achieve the effects of simple operation, improved detection efficiency, and shortened analysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The first step, hydrochloric acid and hydrogen peroxide dissolve the copper sample: Weigh 0.5-1 gram (accurate to 0.0001 gram) of the sample in a 250mL beaker, add 10mL of hydrochloric acid, shake well and fully wet it, let it stand for a few minutes, carefully drip Add about 5 mL of hydrogen peroxide and shake gently. After the sample is dissolved, heat it on an electric heating plate to drive away the excess hydrogen peroxide. After cooling, carefully rinse the watch glass and the beaker wall with deionized water, filter and transfer to a 100mL capacity, wash with 4% HCl until there is no copper ion and make it to volume, ready for use.

[0036] The second step, standard series solution preparation: the high-purity copper treatment method is the same as above, and this solution is used for the determination of standard series and calibration coefficients;

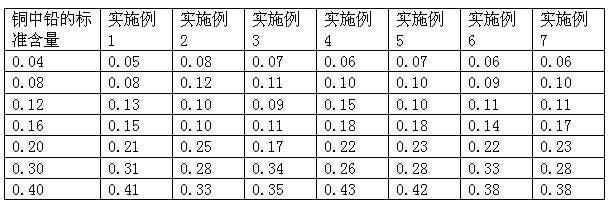

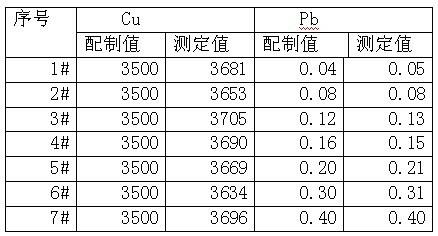

[0037] Among them: the determination of the correction coefficient is mainly based on 4% HCl, adding lead nation...

Embodiment 2

[0051] Embodiment 3, the method for the determination of lead content in copper by inductively coupled plasma emission spectrometry, wherein: the selection of instrument parameters: the IRIS type ICP full-spectrum direct reading spectrometer (Thermoelectric Corporation of America) instrument measurement conditions are set to long-wave 25s, short-wave 5s; sample flushing time 30s; high-frequency output power 950W; atomization pressure 25Psi, auxiliary gas flow 0.5L / min, pump speed 100rpm, atomizer position 5mm. All the other are with embodiment 1.

Embodiment 3

[0052] Embodiment 4, the method for the determination of lead content in copper by inductively coupled plasma emission spectrometry, wherein: the selection of instrument parameters: IRIS type ICP full-spectrum direct reading spectrometer (U.S. Thermoelectric Corporation) instrument measurement conditions are set to long-wave 25s, short-wave 5s; sample flushing time 30s; high-frequency output power 1350W; atomization pressure 30Psi, auxiliary gas flow 0.5L / min, pump speed 100rpm, atomizer position 10mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com