Method for preparing epoxy morpholine quaternary ammonium salt-modified polybenzimidazole anion exchange membrane

An anion exchange membrane, polybenzimidazole technology, which is applied in the field of preparation of epoxymorpholine quaternary ammonium salt modified polybenzimidazole anion exchange membrane, can solve problems such as unfavorable human health and industrialized production, and achieve broad industrial application Prospect, mild reaction conditions, good alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

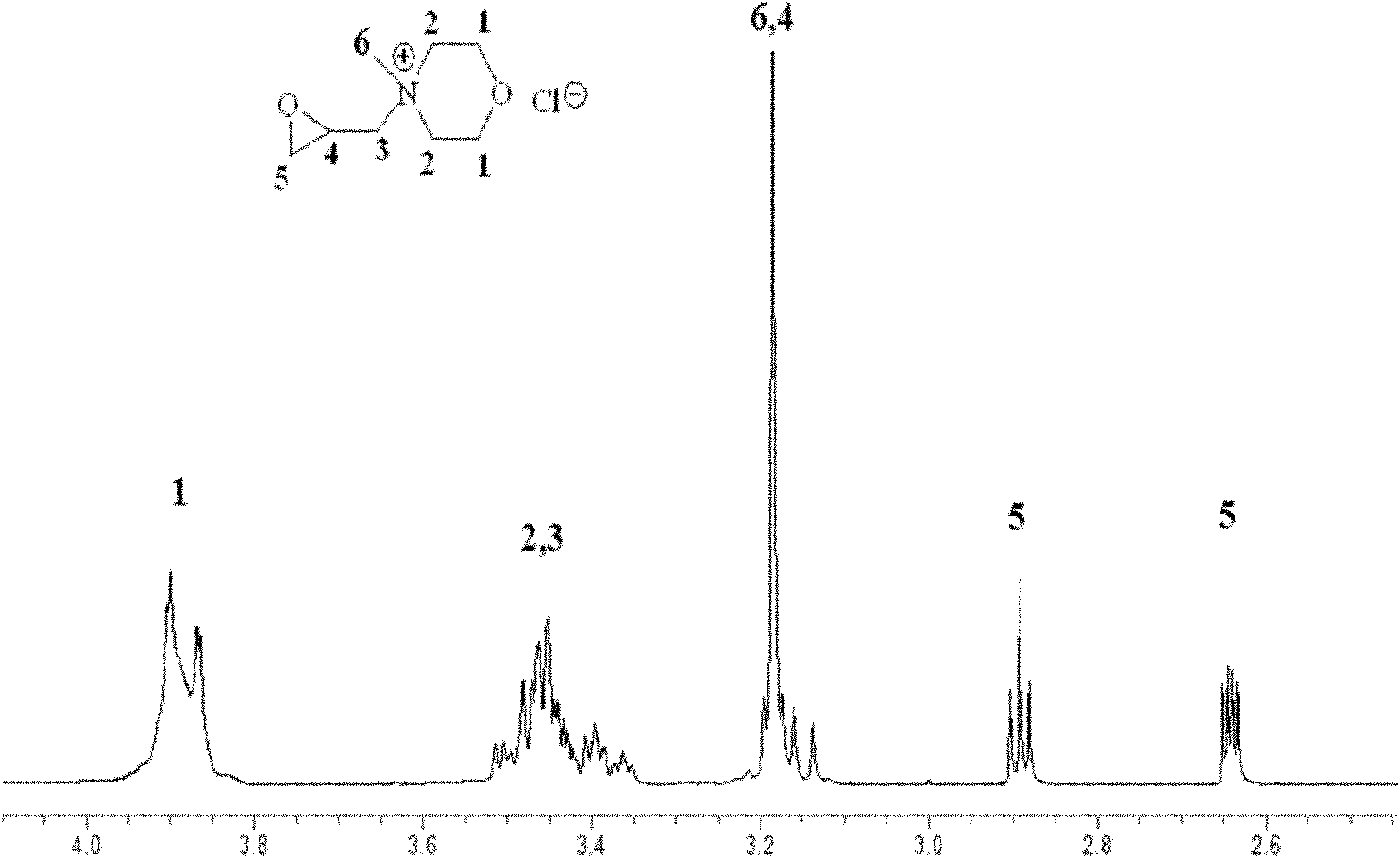

[0027] (1) In a 100ml dry three-necked flask, first add 5ml of acetonitrile, then add 20ml (0.18mol) N-methylmorpholine, 14.7ml (0.18mol) epichlorohydrin, and after fully stirring, vent nitrogen and The temperature was increased to 40°C and the heating was stopped after 48 hours of reaction, and a large amount of white solid was produced. Suction filtration and the obtained epoxymorpholine quaternary ammonium salt were fully washed three times with ether and once with acetone, and then fully dried in a vacuum oven at 50° C. for 10 h until use.

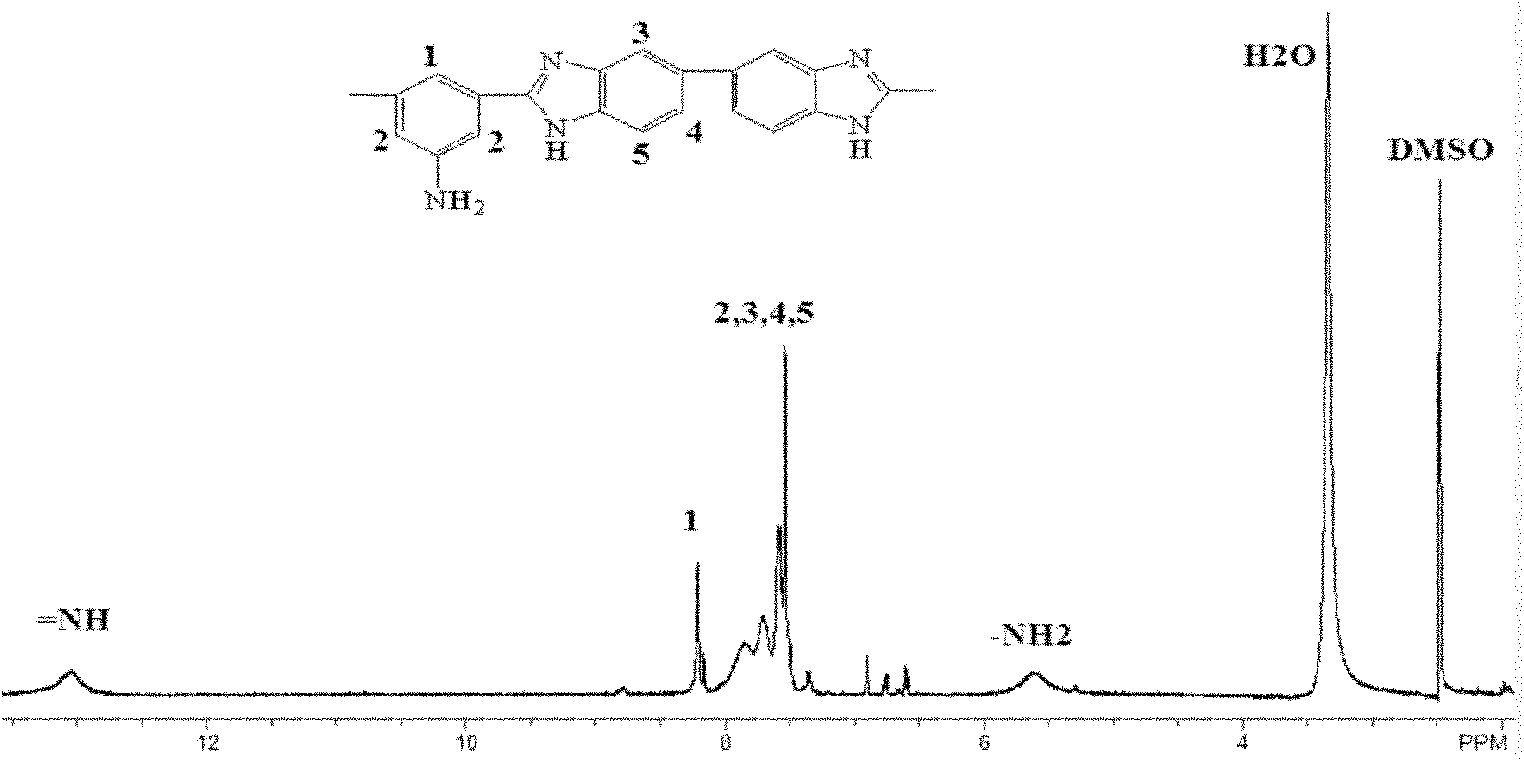

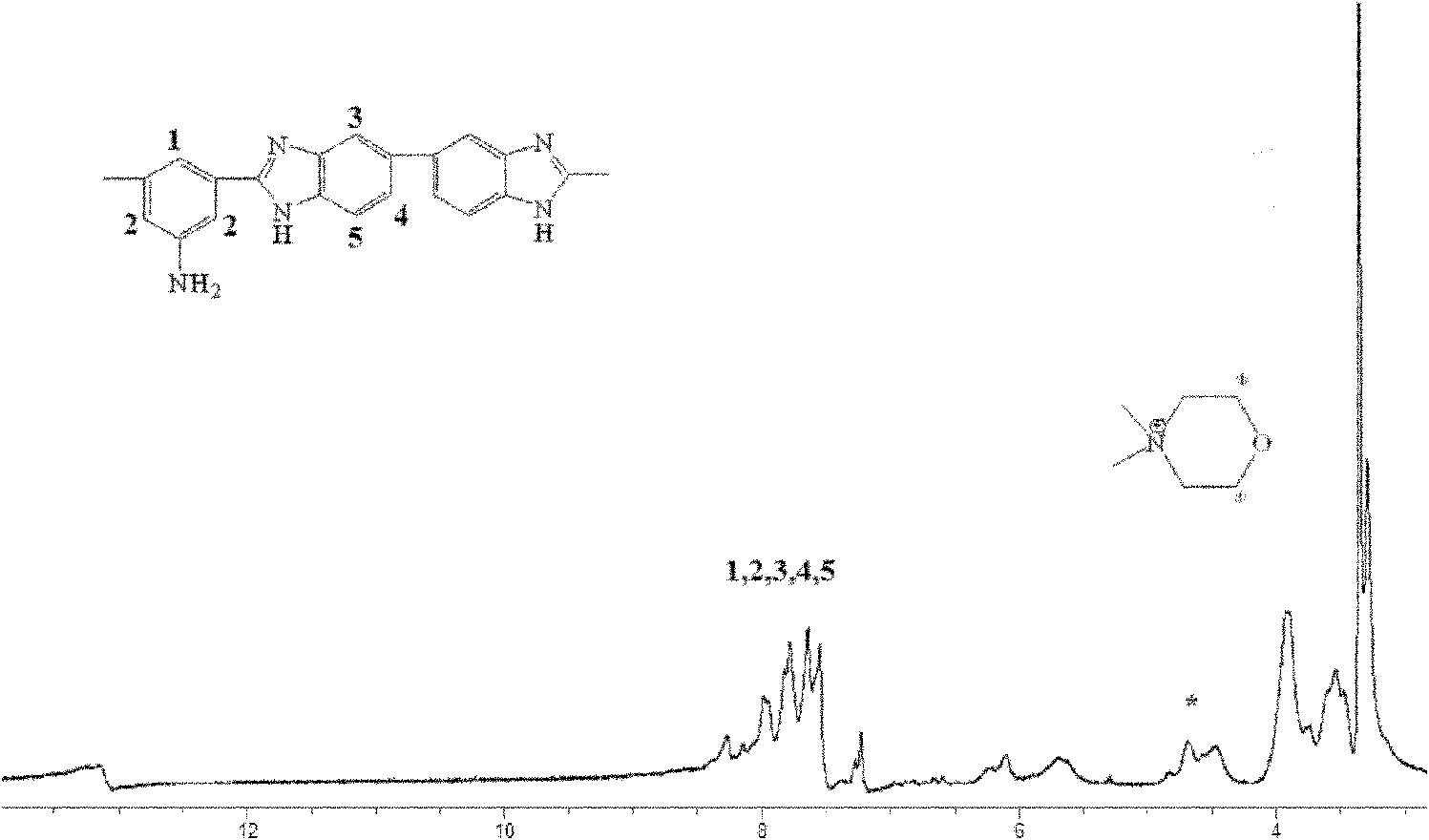

[0028] (2) In a 100ml dry three-necked flask, add 0.646g (2mmol) of amino-containing polybenzimidazole and 17.6ml of dimethyl sulfoxide, protect with nitrogen, and raise the temperature to 80°C. After the amino-containing polybenzimidazole is fully dissolved, the temperature is reduced to room temperature and 0.387 g (2 mmol) of epoxymorpholine quaternary ammonium salt is added, and the temperature is raised to 85° C. and reacted for 10 h...

Embodiment 2

[0032] (1) In a 100ml dry three-necked flask, first add 5ml of acetonitrile, then add 20ml (0.18mol) N-methylmorpholine, 14.7ml (0.18mol) epichlorohydrin, and after fully stirring, vent nitrogen and The temperature was increased to 40°C, and the heating was stopped after 48 hours of reaction, and a large amount of white solid was produced. Suction filtration and the obtained epoxymorpholine quaternary ammonium salt were fully washed three times with ether and once with acetone, and then fully dried in a vacuum oven at 50° C. for 10 h until use.

[0033] (2) In a 100ml dry three-necked flask, add 0.646g (2mmol) of amino-containing polybenzimidazole and 17.6ml of dimethyl sulfoxide, protect with nitrogen, and raise the temperature to 80°C. After the amino-containing polybenzimidazole is fully dissolved, it is lowered to room temperature and 0.580 g (3 mmol) of epoxymorpholine quaternary ammonium salt is added, and the temperature is raised to 85° C. and reacted for 10 hours. After...

Embodiment 3

[0037] (1) In a 100ml dry three-necked flask, first add 5ml of acetonitrile, then add 20ml (0.18mol) N-methylmorpholine, 14.7ml (0.18mol) epichlorohydrin, and after fully stirring, vent nitrogen and The temperature was increased to 40°C, and the heating was stopped after 48 hours of reaction, and a large amount of white solid was produced. Suction filtration and the obtained epoxymorpholine quaternary ammonium salt were fully washed three times with ether and once with acetone, and then fully dried in a vacuum oven at 50° C. for 10 h until use.

[0038] (2) In a 100ml dry three-necked flask, add 0.646g (2mmol) of amino-containing polybenzimidazole and 17.6ml of dimethyl sulfoxide, protect with nitrogen, and heat to 80°C. After the amino-containing polybenzimidazole is fully dissolved, the temperature is reduced to room temperature and 0.774 g (4 mmol) of epoxymorpholine quaternary ammonium salt is added, and the temperature is raised to 85° C. and reacted for 10 hours. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com