Liposome preparation for anticoagulant thrombolytic difunctional fusion protein and preparation method thereof

A technology of fusion proteins and liposomes, which is applied in the directions of liposome delivery, peptide/protein components, and medical preparations of inactive ingredients, etc. Useful for intravenous injections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The factors affecting the encapsulation efficiency of liposomes were screened, and 4 factors with greater influence were selected: the ratio of soybean lecithin to cholesterol (A), the drug concentration (B), the volume of PBS (C), and the ultrasonic time in water bath ( D). Taking these four factors as the investigation factors, each factor takes three levels, and adopts the orthogonal design method L 9 (34) to carry out the experiment. The experimental design is shown in Table 1.

[0016] Table 1 Four-factor three-level orthogonal design table

[0017]

[0018] The experimental results are shown in Table 2:

[0019] Table 2 Orthogonal experiment results

[0020] No.

[0021] Through the analysis in Table 2, it can be seen from the range R that the influence of the four factors on the encapsulation efficiency is in the following order: C>A>D>B. Based on the above results, it is determined that the best recipe process combination for the prepara...

Embodiment 2

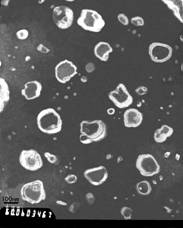

[0023] The liposome emulsion obtained by film dispersion is further reduced and uniform in particle size by probe ultrasound. The ultrasonic power of the probe was 50W, the interval was 2S, and the cumulative time was 5min, 10min, and 15min.

[0024] Table 3 Effect of probe ultrasound time on encapsulation efficiency, particle size and thrombolytic activity of HV12p-rPA liposomes (n=3)

[0025] The ultrasonic probe time(min)

[0026] It can be seen from Table 3 that with the extension of ultrasonic time, the encapsulation rate of liposomes decreased, and the probe ultrasonication for 10 min had little effect on the encapsulation rate compared with ultrasonic 5 min. As the ultrasonic time prolongs, the particle size gradually decreases between 170-140nm. When the ultrasonic time increased from 5 min to 10 min, the thrombolytic activity did not change, but when the ultrasonic time was extended to 15 min, the thrombolytic activity decreased significantly. Considering th...

Embodiment 3

[0028] Determination of encapsulation efficiency: BCA reagent method The principle is similar to that of the Lowery method for protein quantification, that is, under alkaline conditions, the protein and Cu 2+ Complexation and reduction of Cu 2+ into Cu 1+ . BCA and Cu 1+ Combined to form a stable purple-blue complex, there is a high light absorption value at 570 nm and is proportional to the protein concentration, according to which the protein concentration can be determined.

[0029] Encapsulation efficiency = (total protein * dilution factor - free protein) / total protein * dilution factor * 100%

[0030] Take two liposome suspensions, one is to adjust the Zeta potential to flocculate the liposomes, after refrigerated centrifugation, extract the upper supernatant, and measure the free protein content outside the liposome; the other is added to the demulsifier TritonX-100 to destroy The phospholipid bilayer of the plastid releases the protein drug encapsulated in the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com