Preparation method of MnO2 nanoclusters by using graphene as template

A nanocluster, graphene technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems affecting the excellent performance of nanometer effect, large capacity loss, easy to occur agglomeration, etc., achieve excellent electrochemical performance, inhibit Reunion problems, the effect of convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

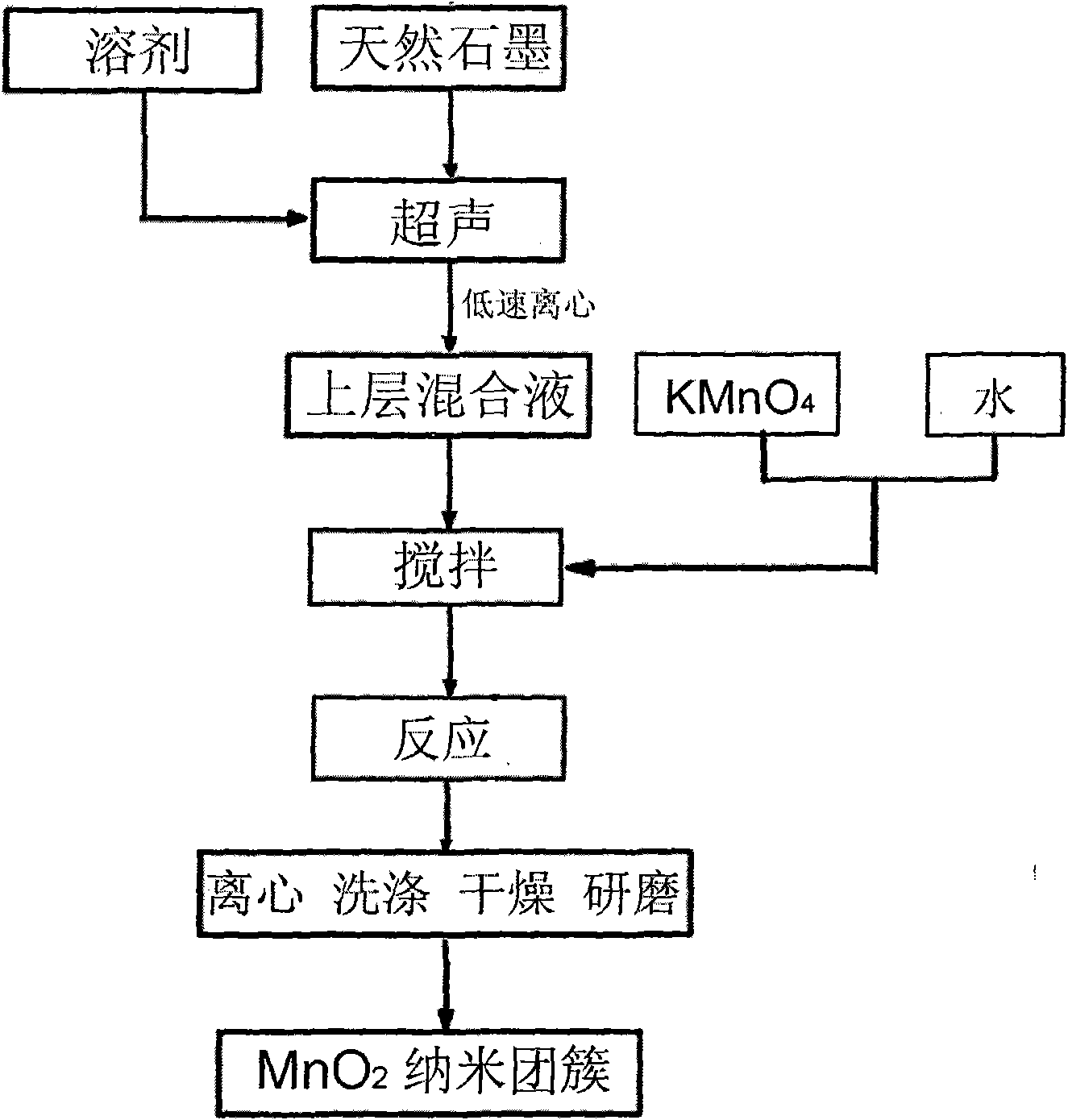

[0018] As shown in the accompanying drawing, graphene of the present invention is template MnO 2 A method for preparing nanoclusters, comprising the following steps:

[0019] Step 1: disperse natural graphite in N-methylpyrrolidone, and then perform ultrasonic treatment;

[0020] Step 2: Centrifuge the mixture obtained in step 1, discard the residual solid at the bottom, and take the mixed solution in the upper layer (ie, the suspension formed by dispersing the raw material graphene in N-methylpyrrolidone);

[0021] Step 3: Incorporate the KMnO 4 Dissolve in water to form KMnO 4 aqueous solution;

[0022] Step 4: KMnO prepared in step 3 4 Add the aqueous solution to the mixed solution prepared in step 2, stir and react for a period of time to obtain a new mixed solution, and the reaction equation is:

[0023] 4KMnO 4 +3C+H 2 O→4MnO 2 +K 2 CO 3 +2KHCO 3 ;

[0024] Step 5: centrifuge, wash, dry and grind the new mixed solution prepared in step 4 to obtain the require...

Embodiment 1

[0028] Step 1: Disperse 10mg of natural graphite in 100mL of N-methylpyrrolidone, and then perform ultrasonic treatment for 10min;

[0029] Step 2: Centrifuge the mixture obtained in step 1 at a low speed (100rpm), discard the residual solid at the bottom, and get the upper layer of the mixed solution (that is, the suspension formed by dispersing the raw material graphene in N-methylpyrrolidone);

[0030] Step 3: Add 40mg of KMnO 4 Dissolve in water to form KMnO 4 aqueous solution;

[0031] Step 4: KMnO prepared in step 3 4 The aqueous solution was added to the mixed solution prepared in step 2, stirred and reacted for 54 hours at 25° C. to obtain a new mixed solution, and the reaction equation was:

[0032] 4KMnO 4 +3C+H 2 O→4MnO 2 +K 2 CO 3 +2KHCO 3 ;

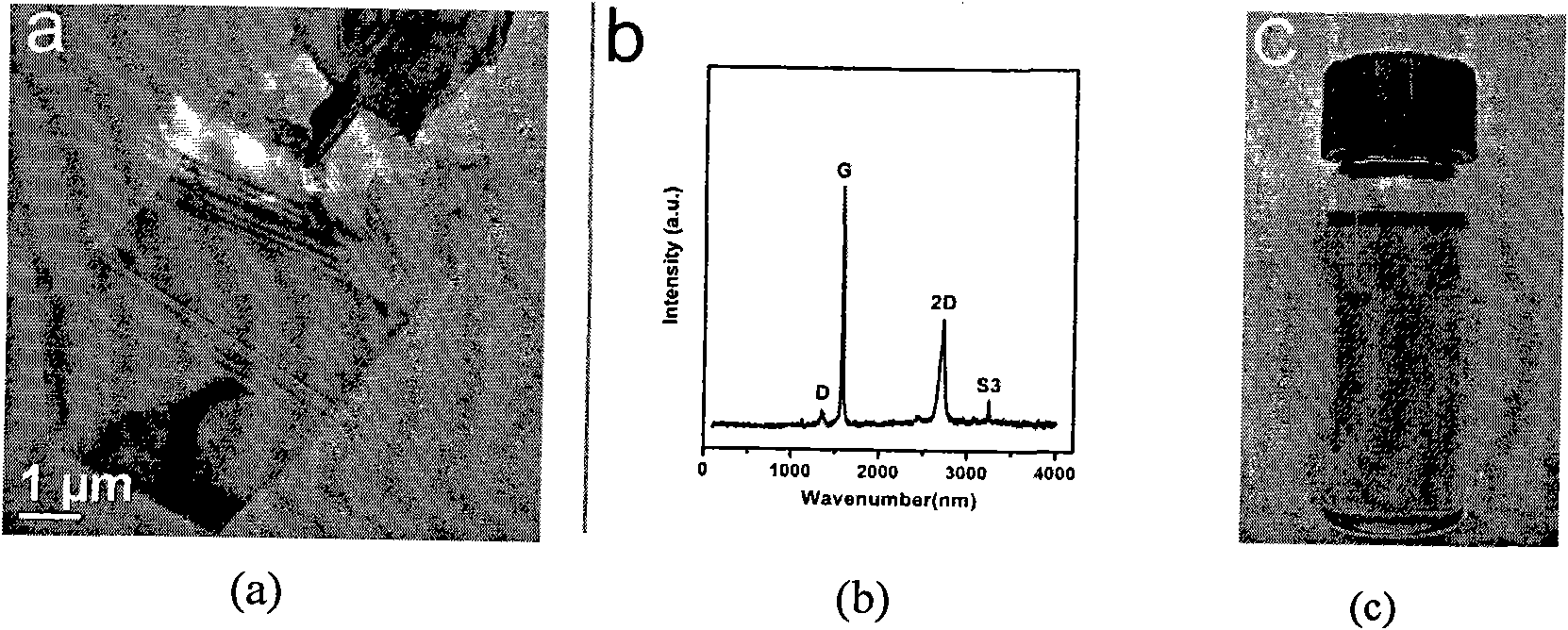

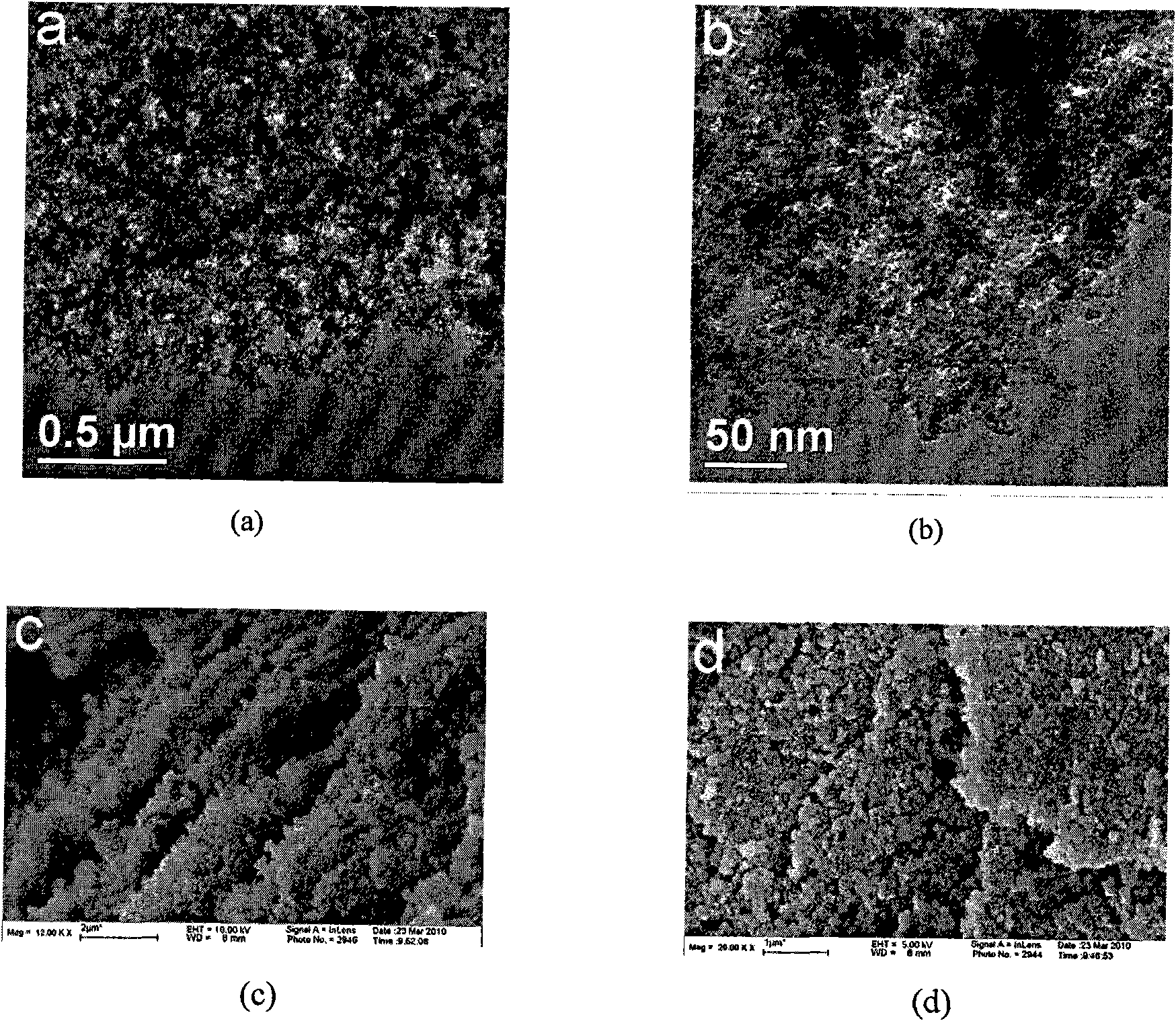

[0033] Step 5: Centrifuge, wash, dry and grind the new mixed solution prepared in step 4 to obtain the required MnO 2 nanoclusters. The transmission electron microscope image of the raw material graphene is as fol...

Embodiment 2

[0035] Step 1: Disperse 1mg of natural graphite in 100mL of N-methylpyrrolidone, and then perform ultrasonic treatment for 30min;

[0036] Step 2: The mixture obtained in step 1 is subjected to low-speed centrifugation (500rpm), the residual solid at the bottom is discarded, and the upper layer of the mixed solution (that is, the suspension formed by dispersing the raw material graphene in N-methylpyrrolidone);

[0037] Step 3: Add 5 mg of KMnO 4 Dissolve in 5mL water to form KMnO 4 aqueous solution;

[0038] Step 4: KMnO prepared in step 3 4 The aqueous solution was added to the mixed solution prepared in step 2, stirred and reacted for 72 hours at 5° C. to obtain a new mixed solution, and the reaction equation was:

[0039] 4KMnO 4 +3C+H 2O→4MnO 2 +K 2 CO 3 +2KHCO 3 ;

[0040] Step 5: Centrifuge, wash, dry and grind the new mixed solution prepared in step 4 to obtain the required MnO 2 nanoclusters. It was determined that the specific capacitance of the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com