Method for preparing carbon nanometer tube loaded type catalyst

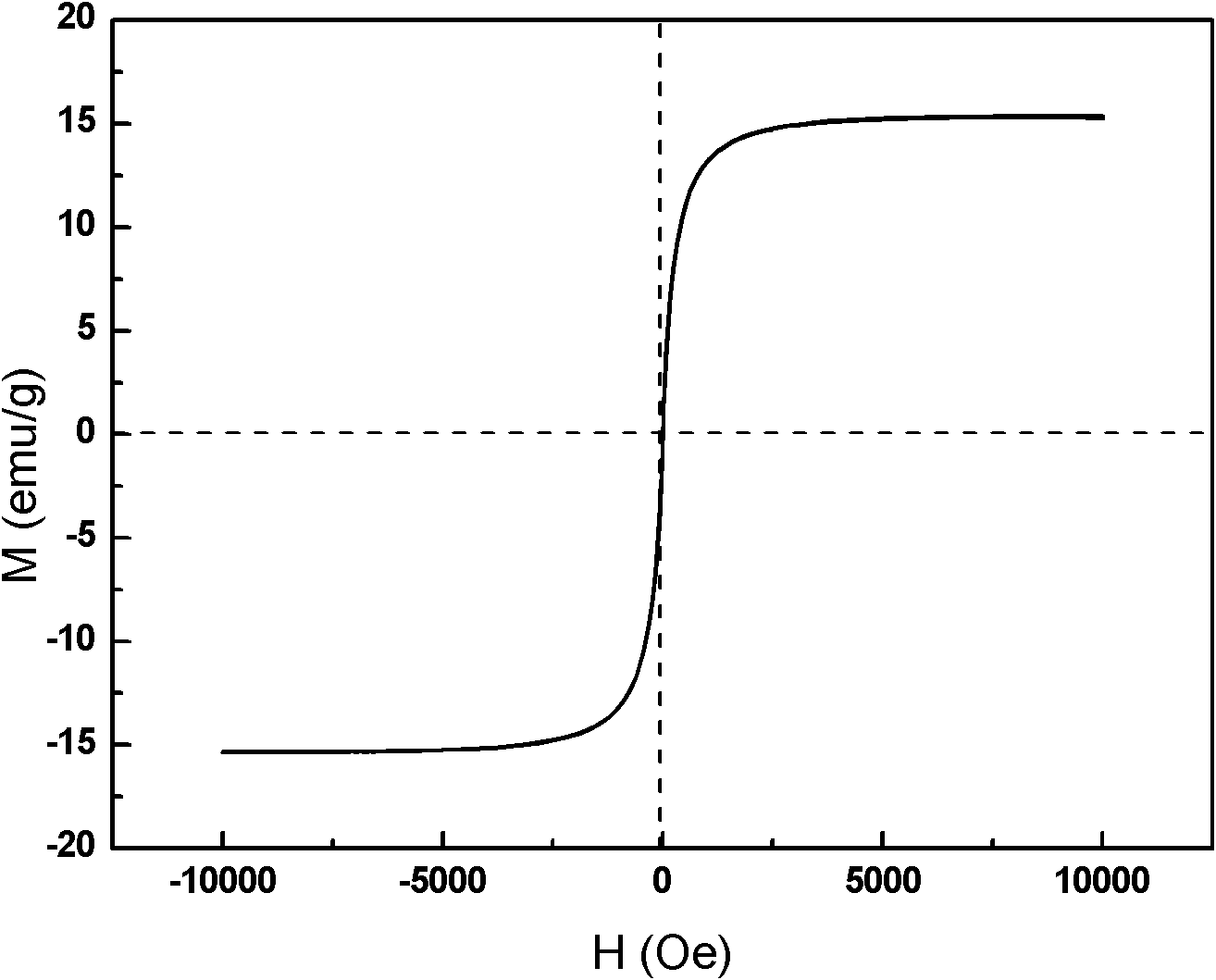

A supported catalyst and carbon nanotube technology are used in the preparation of metal-supported magnetic catalysts using magnetic carbon nanotubes as carriers, and in the field of preparation of carbon nanotube-supported catalysts, which can solve the difficulty of catalyst separation, the loss of carriers and active components , time-consuming and labor-intensive problems, to achieve the effects of efficient separation and recycling, excellent catalytic performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 3.0 g of carbon nanotubes, add 250 ml of concentrated nitric acid, stir at room temperature for 24 h, then wash with deionized water until the pH of the solution is neutral, dry at 70° C. for 12 h, and grind for later use.

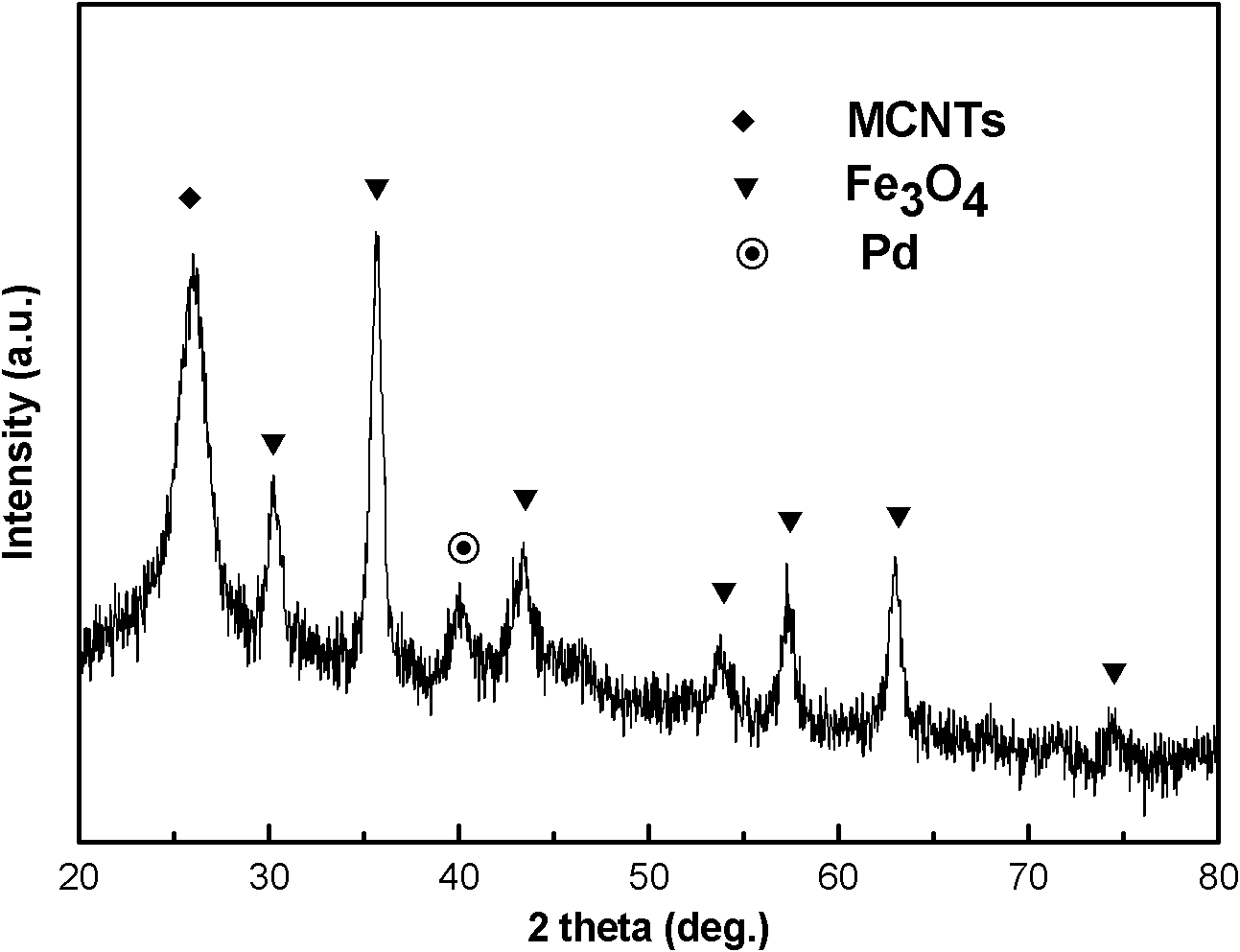

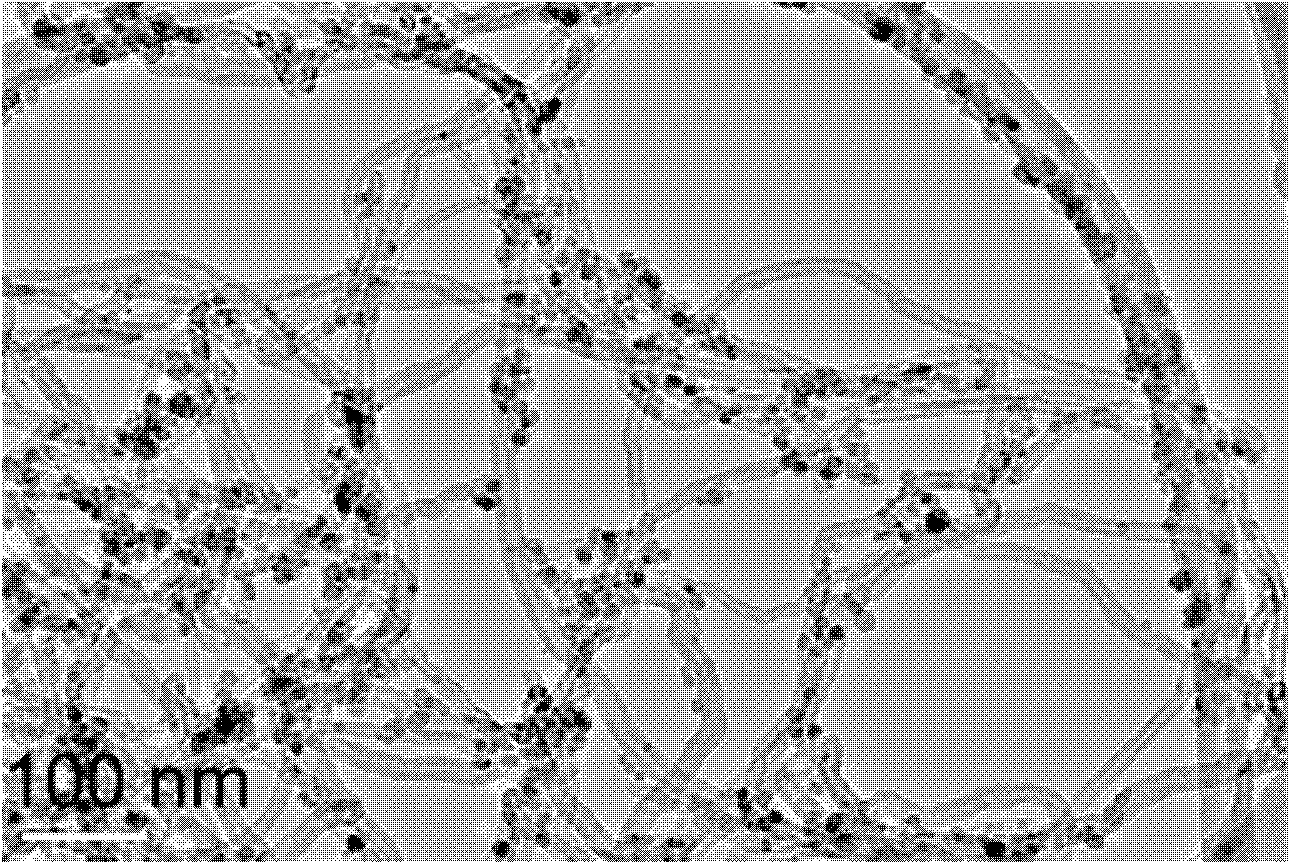

[0026] Weigh 1.0g of pretreated carbon nanotubes, add 60ml of triethylene glycol, ultrasonicate for 5min, then add 1.0g of Fe(acac) 3 , continue to sonicate for 10min, pass nitrogen protection, heat until the solution boils, reflux for 0.5h, cool to room temperature, wash with ethanol until colorless, and blow dry overnight at 80°C to obtain Fe 3 o 4 / MCNT magnetic carrier.

[0027] Weigh Pd(acac) 2 0.0150g, 0.03820g of 1,2-hexadecanediol, add 20ml of dioctyl ether, pass through nitrogen protection and heat to 100°C, add 0.5g of Fe 3 o 4 / MCNT magnetic carrier, continue to heat to boiling, reflux for 0.5h, cool to room temperature, close the protective gas and carry out suction filtration, wash with absolute ethanol until colorless, and bl...

Embodiment 2

[0029] Weigh 3.0 g of carbon nanotubes, add 250 ml of concentrated nitric acid, stir at room temperature for 24 hours, then wash with deionized water until the pH of the solution is neutral, dry at 100°C overnight, and grind for later use.

[0030] Weigh 1.0 g of the pretreated carbon nanotubes, add 60 ml of triethylene glycol, ultrasonicate for 5 minutes, and then add Fe(acac) 3 1.5g, continue to sonicate for 10min, feed nitrogen, heat until the solution boils, reflux for 0.5h, cool to room temperature, wash with ethanol until colorless, and dry at 80°C overnight to obtain Fe 3 o 4 / MCNT magnetic carrier.

[0031] Weigh Pd(acac) 2 0.0446g, 0.1135g of 1,2-hexadecanediol, 20ml of dioctyl ether, blowing nitrogen gas, heating to 100°C, adding 0.5g Fe 3 o 4 / MCNT magnetic carrier, continue heating to boiling, reflux for 0.5h, cool to room temperature, turn off the protective gas, filter with suction, wash with absolute ethanol until colorless, and dry at 80°C overnight to obta...

Embodiment 3-5

[0033] The mass ratios of Fe(acac)3 and MCNTs were changed to 2:1, 3:1 and 4:1 respectively, and the pretreatment conditions and catalyst preparation process were the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com