Ag3PO4/Mg-Al LDO (Layered Double Oxide) visible light composite photo catalyst, preparation and application thereof

A composite photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems that have not been reported before, and achieve environmental friendliness, easy industrial production, and strong adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, weigh 76.24g of magnesium chloride hexahydrate and 45.27g of aluminum chloride hexahydrate into 262.5ml of water, and stir until completely dissolved to obtain a mixed salt solution. Separately weigh 52.5g of sodium hydroxide and 66.38g of sodium carbonate into 375ml of water and stir until completely dissolved to obtain a mixed alkali solution. Pour the mixed alkali solution into a three-necked flask, place it in an oil bath, heat the oil bath to 50°C, and use three constant pressure droppers to add the mixed salt solution to the mixed alkali solution drop by drop. After the dropwise addition, the oil bath was heated to 90°C and kept for 4h. After the incubation, wash with deionized water and absolute ethanol 6 times and 2 times, respectively, and dry at 90 °C for 24 h to obtain Mg-Al-CO 3 LDH.

Embodiment 2

[0031] At room temperature, weigh 4.8g of disodium hydrogen phosphate dodecahydrate and add it to 150ml of water, stir until completely dissolved, then weigh 3g of the Mg-Al-CO prepared in Example 1 3 LDH was added to the above solution, and the suspension was stirred for 10 min. Weigh 2.3g of silver nitrate and add it into 50ml of water, and stir until completely dissolved in the dark, then add to the above suspension, and stir at room temperature for 24h in the dark. After the reaction, wash with distilled water for 6 times, and dry at 70°C for 24 hours. Calcinate the powder in air at 400°C for 4h to obtain Ag 3 PO 4 / Mg-Al LDO(Ag 3 PO 4 wt% = 50%).

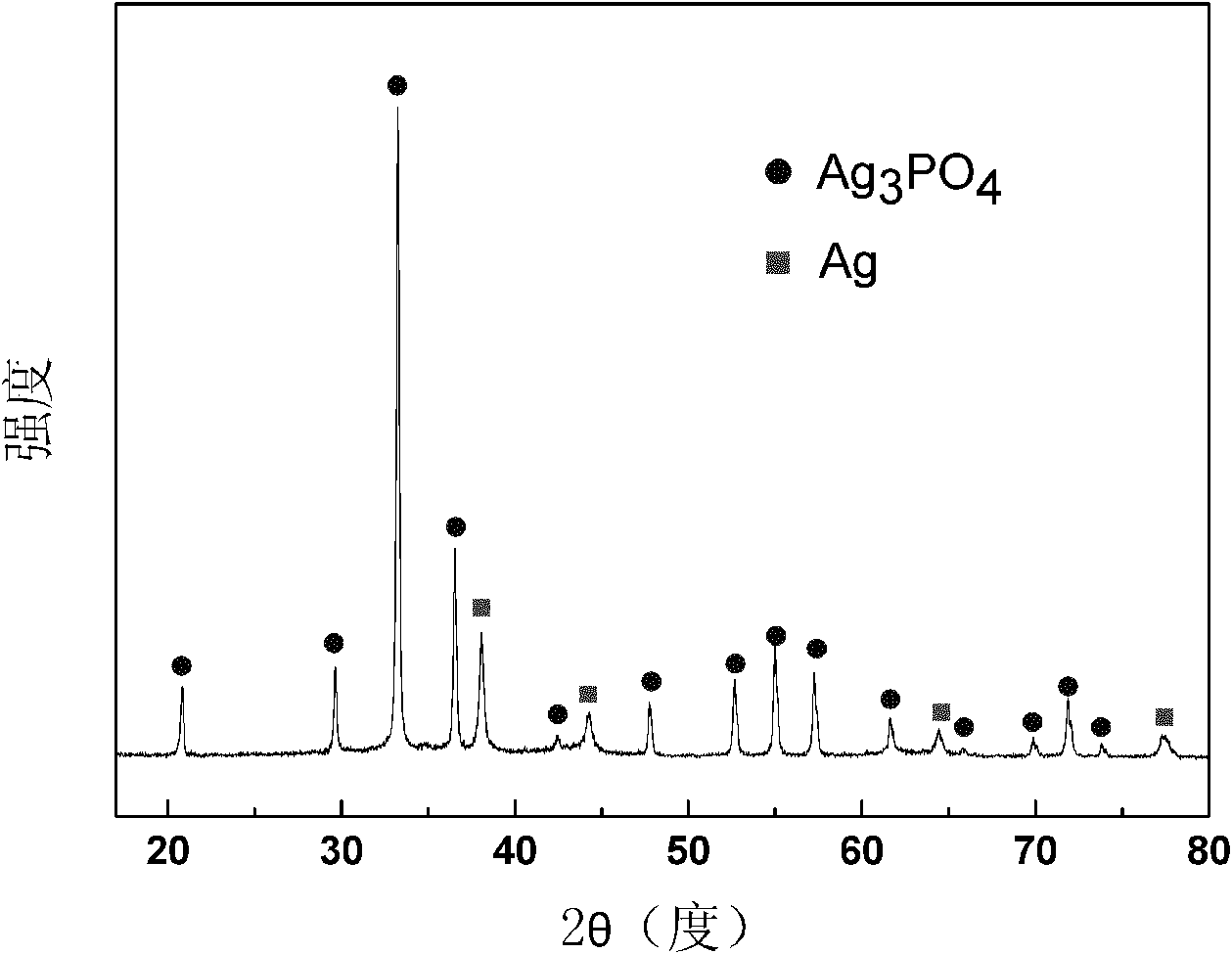

[0032] figure 1 Ag prepared for this example 3 PO 4 X-ray diffraction pattern of / Mg-Al LDO, the Ag shown in the figure 3 PO 4 The characteristic peaks are very obvious, and at the same time, the characteristic peaks of elemental Ag also appear, indicating that Ag 3 PO 4 The chemical environment of Ag in the compos...

Embodiment 3

[0034] At room temperature, weigh 1.6g of disodium hydrogen phosphate dodecahydrate and add it to 150ml of water, stir until completely dissolved, then weigh 3g of the Mg-Al-CO prepared in Example 1 3 LDH was added to the above solution, and the suspension was stirred for 10 min. Weigh 0.77g of silver nitrate and add it into 50ml of water, and stir until completely dissolved in the dark, then add it to the above suspension, and stir at room temperature for 24 hours in the dark. After the reaction, wash with distilled water for 6 times, and dry at 70°C for 24 hours. Calcinate the powder in air at 400°C for 4h to obtain Ag 3 PO 4 / Mg-Al LDO(Ag 3 PO 4 wt% = 25%).

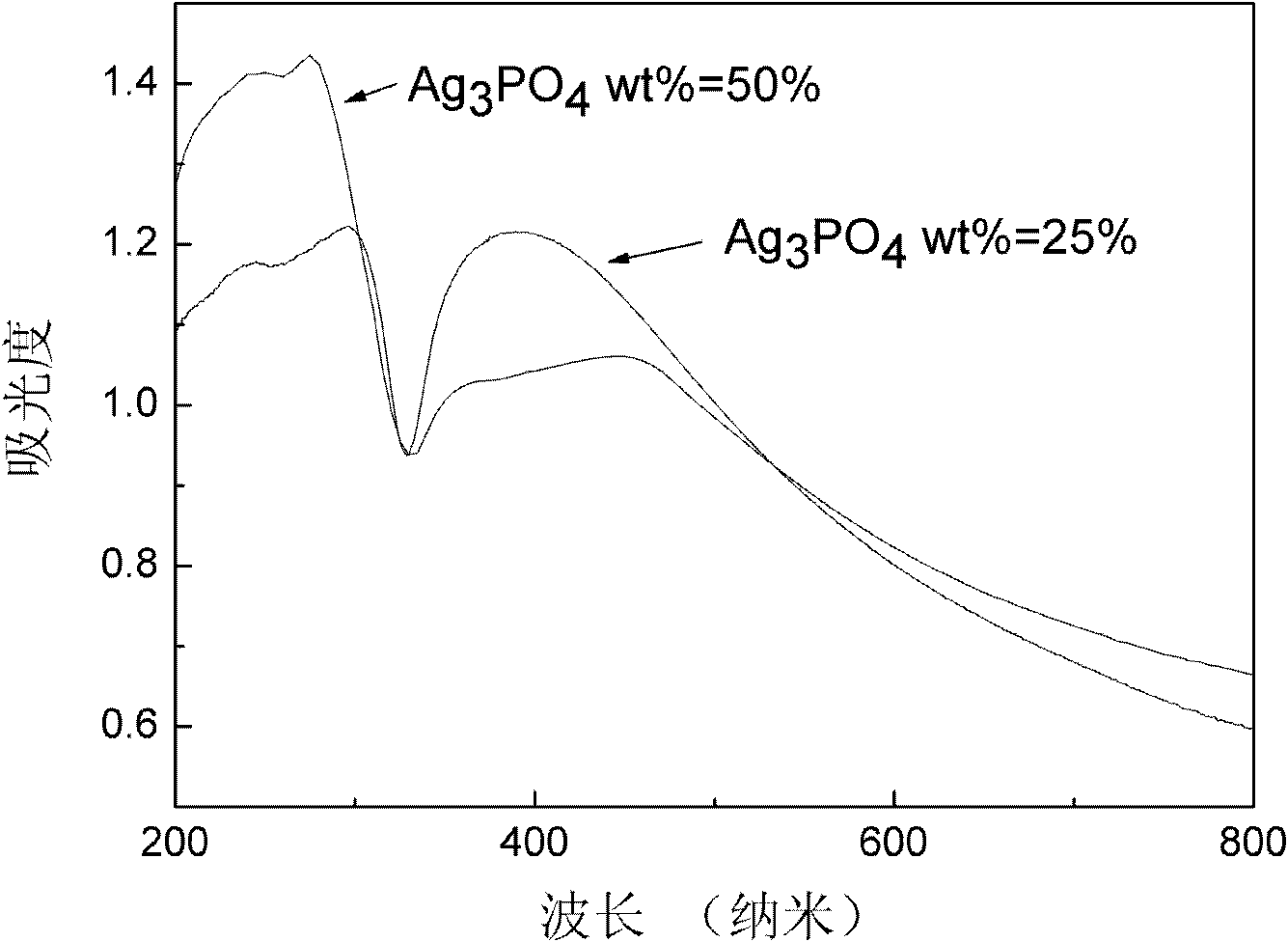

[0035] figure 2 The Ag prepared in this example is given 3 PO 4 / Mg-Al LDO(Ag 3 PO 4 wt%=25%) ultraviolet-visible light diffuse reflectance spectrum, the composite catalyst has strong absorption in the visible light region.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com