Three-axis capacitive micro accelerometer based on silicon on insulator (SOI) process and micropackage technology

An accelerometer and acceleration technology, applied in the direction of microstructure technology, measurement acceleration, multi-dimensional acceleration measurement, etc., to achieve the effects of shortening the processing cycle, solving packaging problems, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

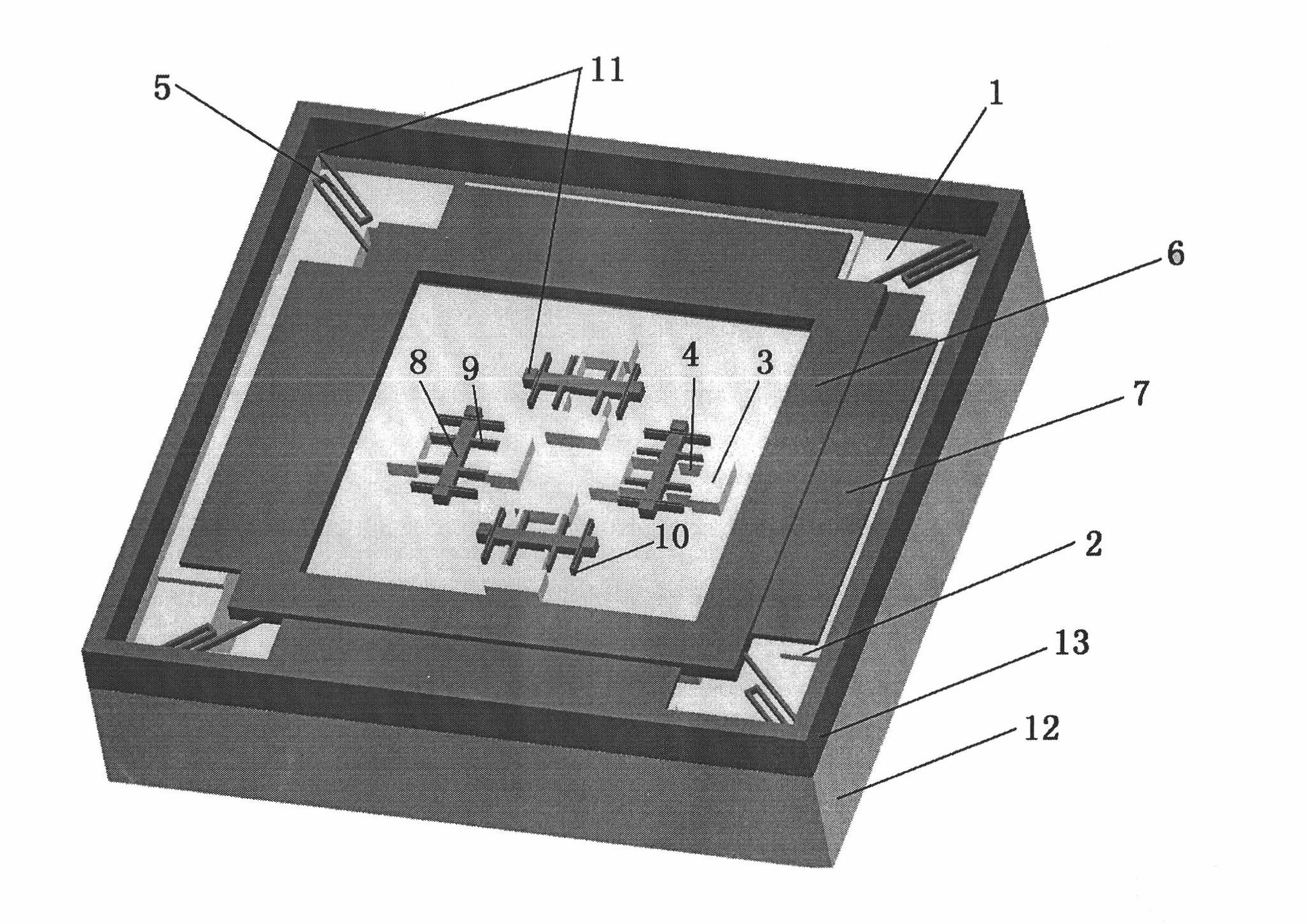

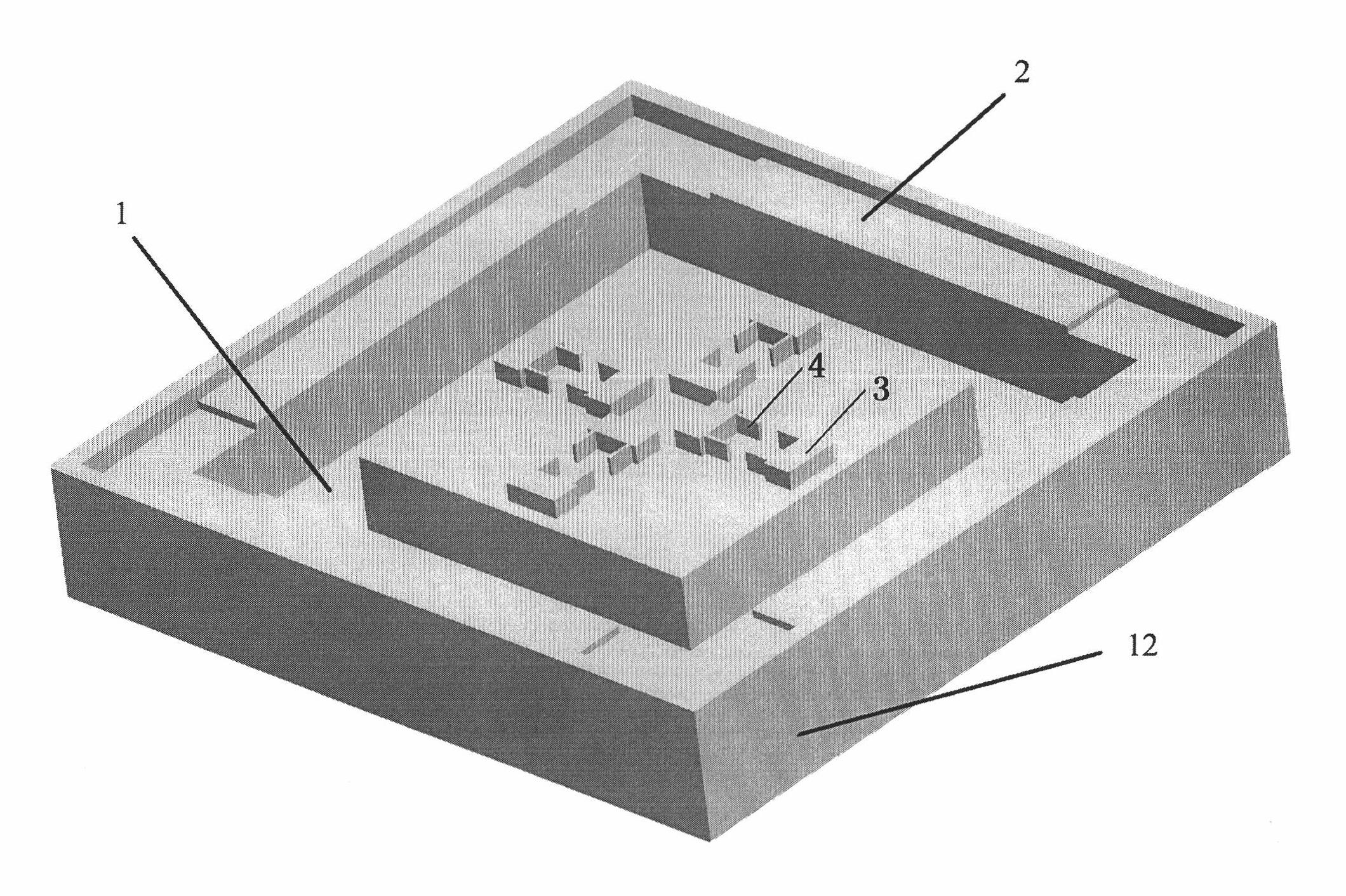

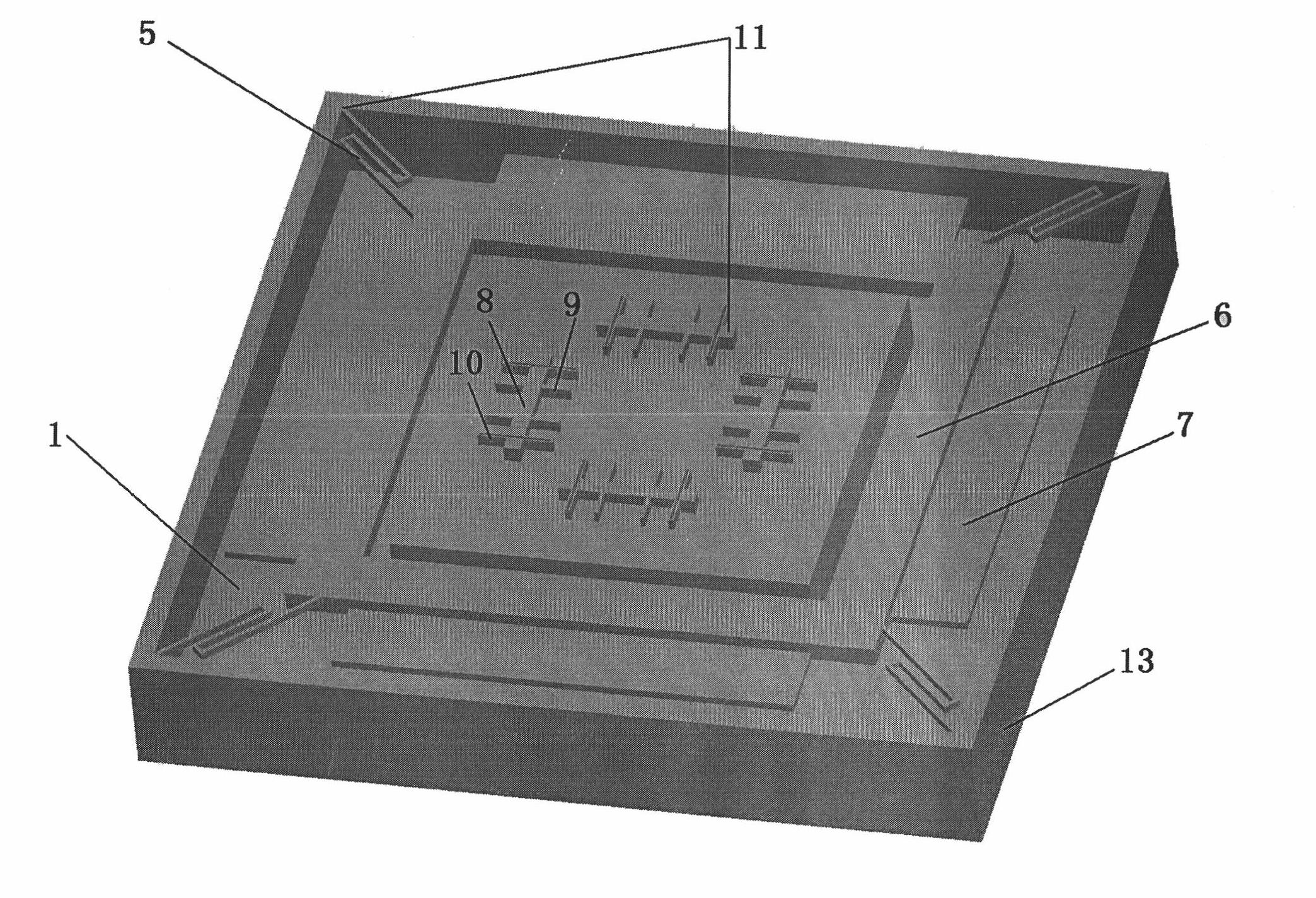

[0015] like figure 1 As shown, the present invention comprises: lower substrate 12, upper substrate 13 (for convenience of observation, the upper substrate omits its encapsulation cover, is a partial sectional view), each substrate is divided into an inner layer structure and an outer layer structure, and the groove 1 is located between the inner structure and the outer structure. In the upper substrate 13 , the Z-axis mass block 6 suspended in the groove 1 is anchored to the anchor points 11 at the four corners of the outer structure through four flexible beams 5 . The Z-axis movable plate 7 protrudes outward from the four sides of the Z-axis mass block 6 . The planar mass 8 is anchored to the anchor point 11 of the inner layer structure of the upper substrate 13 through the return beam 10 . The planar movable plate 9 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com