Method for pretreating 2-methyl-4-chlorophenoxy acetic acid pesticide production wastewater

A production wastewater and pretreatment technology, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex recovery phase components, inability to meet industrial production, and high treatment costs , to achieve obvious environmental and economic benefits, to ensure stable and up-to-standard discharge, and to achieve high removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

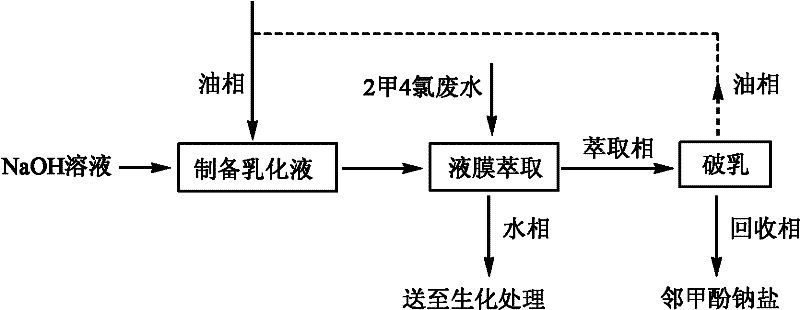

Method used

Image

Examples

Embodiment 1

[0025] Take surfactant L-113A 30L, additive liquid paraffin 60L and film solvent aviation kerosene 910L to form a liquid film oil phase and add it to a high-shear emulsifier, control the number of revolutions to 2980 rpm, and add 15% sodium hydroxide solution at the same time 500L, high-speed shearing for 30 minutes to obtain a water-in-oil emulsion. Disperse 900L of the emulsion in 5400L of production wastewater, stir and extract at 130 rpm for 30 minutes, and let stand to separate layers. After the lower water phase is clarified, the two phases of oil and water are separated, and the water phase enters the biochemical treatment device for conventional treatment. The upper oil phase (extraction phase) enters the electrostatic demulsification device, the operating voltage is controlled to 23V, and the current is 8-10A. After 30 minutes of demulsification, the oil layer and the water layer are separated. The oil layer is reused to prepare the emulsion, and the water layer is re...

Embodiment 2

[0027] Take 20L of surfactant L-113A, 50L of additive liquid paraffin, and 930L of film solvent aviation kerosene to form a liquid film oil phase and add it to a high-shear emulsifier, control the number of revolutions to 3000 rpm, and add 20% sodium hydroxide solution at the same time 670L, make milk for 30 minutes, and the water-in-oil emulsion is obtained. Disperse 600L of the emulsion in 6000L of production wastewater, control the rotation speed at 130 rpm, stir and extract for 45 minutes, and let stand to separate layers. After the lower water phase is clarified, the oil and water phases are separated, the water phase enters the biochemical treatment device, and the upper oil phase (extraction phase) enters the electrostatic demulsification device. Operation is the same as in Example 1, and the obtained aqueous layer contains 26.2% sodium o-cresate.

Embodiment 3

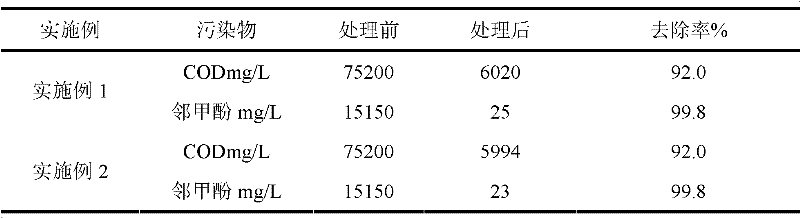

[0029] Test the wastewater after the wastewater pretreatment method of the present invention, and see the table below for each index before and after treatment:

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com