Method for non column chromatography separation and purification of witloof acid from Echinacea purpurea extractive

A technology of echinacea purpurea extract and chromatographic separation, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of cumbersome column chromatography operation steps, high requirements for chromatographic equipment, difficult industrial production, etc., and achieve easy continuous The effect of efficient operation, cost reduction and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

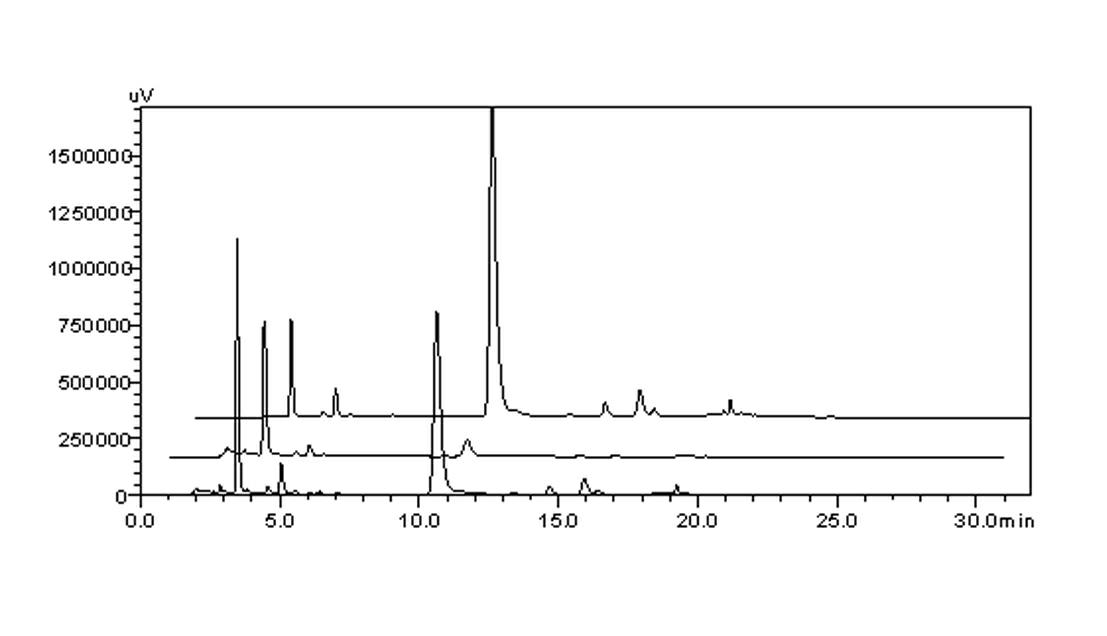

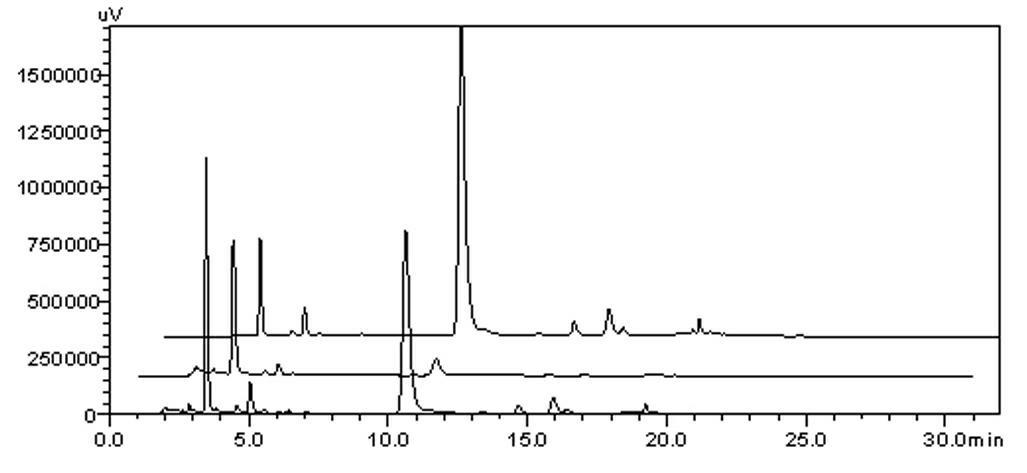

Image

Examples

Embodiment 1

[0014] (1) Dissolution extraction process:

[0015] Get 3g3.6% cichoric acid extract, add 50ml extraction solvent, the extraction solvent of the present embodiment is acetonitrile: water=1:4, adjust pH with a small amount of acid to be 4, ultrasonic extraction 30min, under the regulation of 10000rpm centrifugal 5min, The supernatant can be obtained, and the one-time extraction efficiency is above 98%.

[0016] (2) Allocation enrichment process:

[0017] Measure 40ml of the supernatant, add 8g of anhydrous magnesium sulfate and 2g of sodium chloride, stir, and ultrasonicate for 2 minutes to promote the dissolution of the salt. The original homogeneous solution gradually appears stratified. Centrifuge at 10,000rpm for 5min to obtain two layers with clear boundaries. . Wherein the volume of the upper layer solution where cichoric acid is located is about 4ml, accounting for 1 / 10 of the volume of the original solution, and the recovery rate of cichoric acid in this step is 85%. ...

Embodiment 2

[0021] (1) Dissolution extraction process:

[0022] Get the cichoric acid extract of 100g4%, add 1100ml extraction solvent; The extraction solvent of the present embodiment is acetone: water=1:2,

[0023] Use formic acid to adjust the pH to about 3, ultrasonically extract for 30 minutes, and centrifuge at 10,000 rpm for 5 minutes to obtain the supernatant, and the extraction efficiency is above 95%.

[0024] (2) Allocation enrichment process:

[0025] Take 1100ml of supernatant, add 120g of dipotassium hydrogen phosphate and 60g of sodium chloride, stir, and ultrasonically promote the dissolution of the salt. The original homogeneous solution gradually becomes stratified. Centrifuge at 10,000rpm for 5min to obtain two layers with clear boundaries. Wherein the volume of the upper layer solution where cichoric acid is located is 130ml.

[0026] (3) Drying and purification process:

[0027] Take 130ml of the upper layer solution, add 300ml of chloroform and absolute ethanol (v...

Embodiment 3

[0029] (1) Dissolution extraction process:

[0030] Get the cichoric acid extract of 1000g4.5%, add the mixture of 20000ml ethanol and water, the extraction solvent of the present embodiment is ethanol: water=1:2,

[0031] Use 170ml of formic acid to adjust the pH to about 2, ultrasonically extract for 30 minutes, and centrifuge at 10,000rpm for 5 minutes to obtain the supernatant, and the extraction efficiency is above 95%.

[0032] (2) Allocation enrichment process:

[0033] Take 20,000ml of supernatant, add 3,000g of ammonium sulfate and 750g of potassium chloride, stir, and ultrasonically promote the dissolution of the salt. The original homogeneous solution gradually becomes stratified. Centrifuge at 10,000rpm for 5min to obtain two layers with clear boundaries. Wherein the volume of the upper layer solution where cichoric acid is located is 2500ml.

[0034] (3) Drying and purification process:

[0035] Get 2500ml upper layer solution, add 5000ml chloroform and dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com