Cementitious capillary crystalline waterproof material capable of quickly repairing cracks

A technology for infiltrating crystalline, waterproof materials, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. problems, to achieve the effect of good crack prevention, rapid growth promotion, and strong water pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

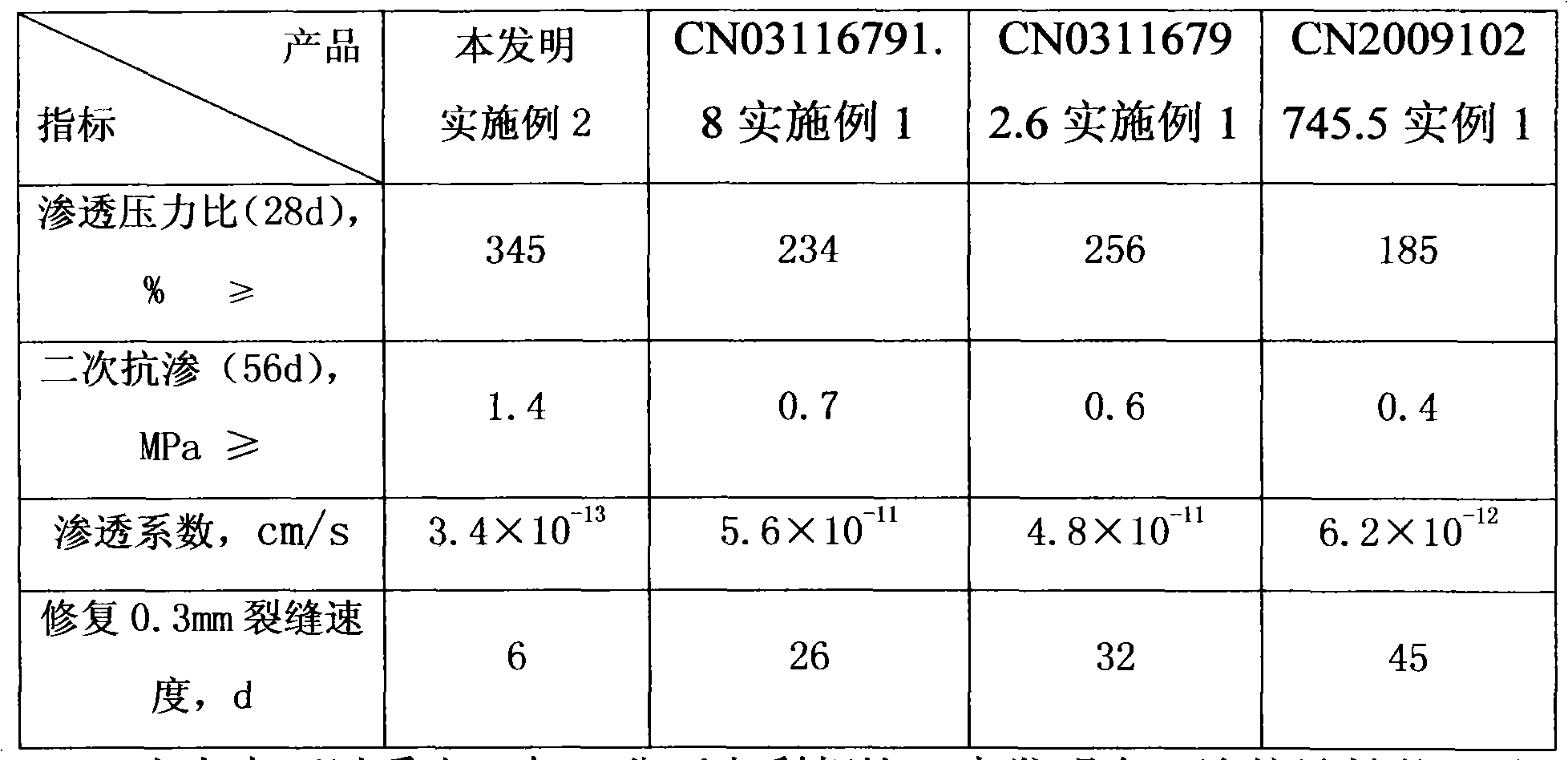

Examples

Embodiment 1

[0052] Portland cement 35%

[0053] Bulking agent 7%

[0054] Quartz sand (80 mesh) 8%

[0055] Quartz sand (325 mesh) 7%

[0056] Silica fume 10%

[0057] UNF-5 naphthalene superplasticizer 25%

[0058] Sodium Gluconate 0.6%

[0061] Metasilicate 5%

Embodiment 2

[0065] Portland cement 30%

[0066] Sulphoaluminate cement 8%

[0067] Bulking agent 9%

[0068] Quartz sand (100 mesh) 10%

[0069] Quartz sand (325 mesh) 5%

[0070] Ground Mineral Powder 12%

[0071] Naphthalene superplasticizer 30%

[0072] Sodium Gluconate 0.5%

[0073] Sodium silicate 8%

[0074] Oxalic Acid 3%

Embodiment 3

[0078] Portland cement 45%

[0079] Bulking agent 7%

[0080] Quartz sand (80-120 mesh) 10%

[0081] Quartz sand (325 mesh) 2%

[0082] Fly Ash 8%

[0083] Polycarboxylate superplasticizer 26%

[0084] Tartaric acid 0.5%

[0085] Sodium silicate 4%

[0086] Sodium Carbonate 2%

[0087] Metasilicate 5%

[0089] Lithium Carbonate 0.6%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com