Preparation method of in-situ hybrid reinforced butadiene-acrylonitrile-isoprene copolymer

A technology of isoprene and butadiene, which is applied in the field of synthetic rubber preparation, can solve the problems of complicated use of microcrystalline cellulose, and achieve the effects of good wet skid resistance, good processing performance and high tensile stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

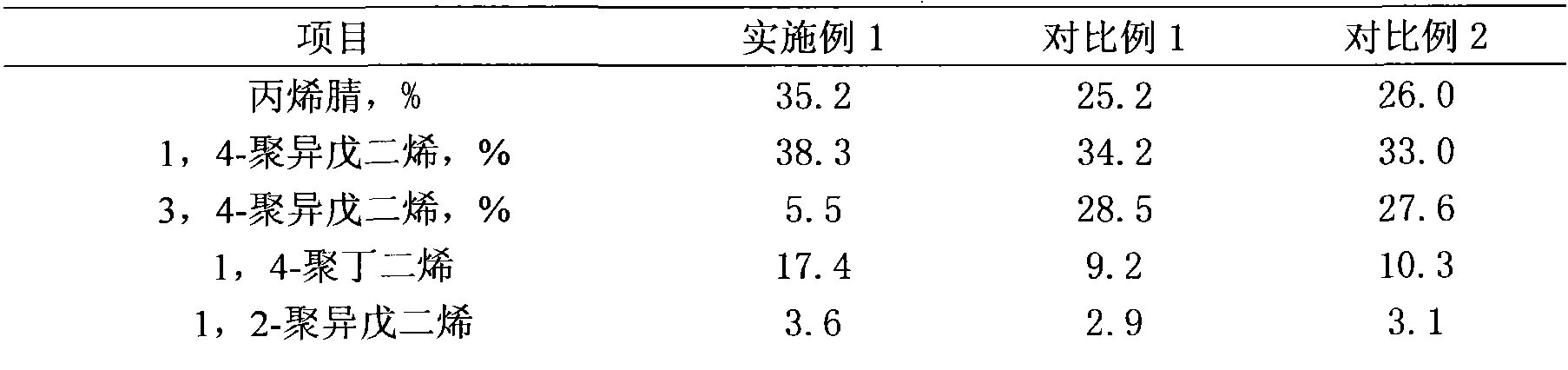

Embodiment 1

[0030] Add 200 parts of water, 5 parts of fatty acid sodium, and 28 parts of isoprene into a 10L polymerization kettle, and pass nitrogen gas to test the pressure. After confirming that there is no leakage in the polymerization kettle, replace it with nitrogen several times, and then add 36 parts of butadiene and 36 parts of 1 part of acrylonitrile (I / B / A: 28 / 36 / 36), drop 1 part of compound reinforcing agent (the mass ratio of vinyltetraethoxysilane and microcrystalline cellulose is 4:6), start the polymerization kettle Stir for 10 minutes, and pour cold water into the polymerization kettle to cool down. When the temperature of the polymerization kettle drops to 10°C, add 0.3 parts of initiator persulfate and 0.5 parts of tertiary dodecyl mercaptan, and react at 20°C for 12 hours. The conversion rate was controlled at 75%, and 0.1 part of terminator diethylhydroxylamine was added. The rubber is condensed after being degassed, and the product of the present invention is obtaine...

Embodiment 2

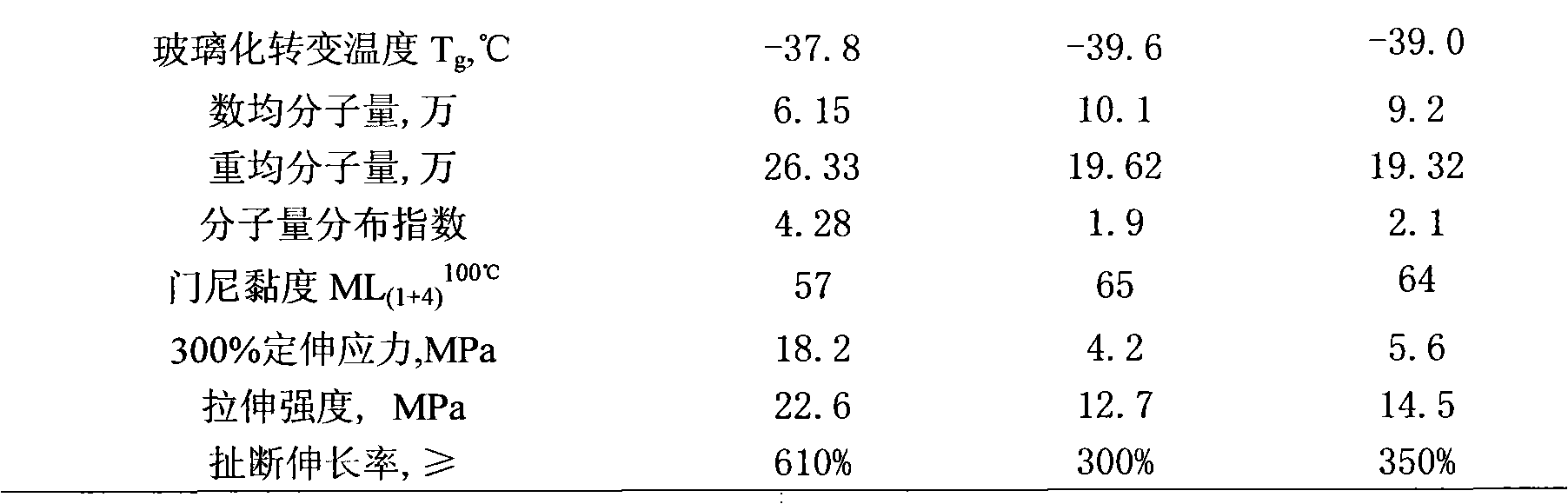

[0039] The formulation and conditions of the polymerization system are the same as those in Example 1, except that the monomer ratio of isoprene, butadiene and acrylonitrile and the amount of molecular weight regulator mercaptan are different. The monomer ratio of this embodiment is 25 parts of isoprene, 50 parts of butadiene and 25 parts of acrylonitrile (I / B / A: 25 / 50 / 25), the molecular weight regulator tert-dodecyl mercaptan consumption is 0.38 part, and 0.6 part of compound reinforcing agent is added dropwise (vinyl four The mass ratio of ethoxysilane to microcrystalline cellulose is 4:6). The structure and properties of the samples were tested by classical methods. 1 H-NMR detection analysis showed that no acrylonitrile homopolymer block (block polyacrylonitrile) existed. The experimental results are shown in Table 2.

Embodiment 3

[0045] The formulation and conditions of the polymerization system are the same as those in Example 1, except that the ratio of isoprene, butadiene, and acrylonitrile monomers and the amount of molecular weight regulator mercaptan are different. The monomer ratio of this embodiment is 22 parts of isoprene, 52 parts of butadiene and 26 parts of acrylonitrile (I / B / A: 22 / 52 / 26), the molecular weight regulator tert-dodecyl mercaptan consumption is 0.30 part, and 1 part of compound reinforcing agent is added dropwise (vinyl four The mass ratio of ethoxysilane to microcrystalline cellulose is 5:5). The structure and properties of the samples were tested by classical methods. 1 H-NMR detection analysis showed that no acrylonitrile homopolymer block (block polyacrylonitrile) existed. The experimental results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com