Heating slag melting agent for smelting low-silicon liquid iron and preparation method of the heating slag melting agent

A technology of molten iron and slag agent, which is applied in the field of metallurgy, can solve the problems of low-silicon molten iron smelting, such as the difficulty of heating, the inability to improve the effect of low-silicon molten iron hydration slag, and speed up the speed of low-silicon molten iron slagging, so as to achieve good thermal conductivity, silicon The content is stable and the effect of improving the refining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

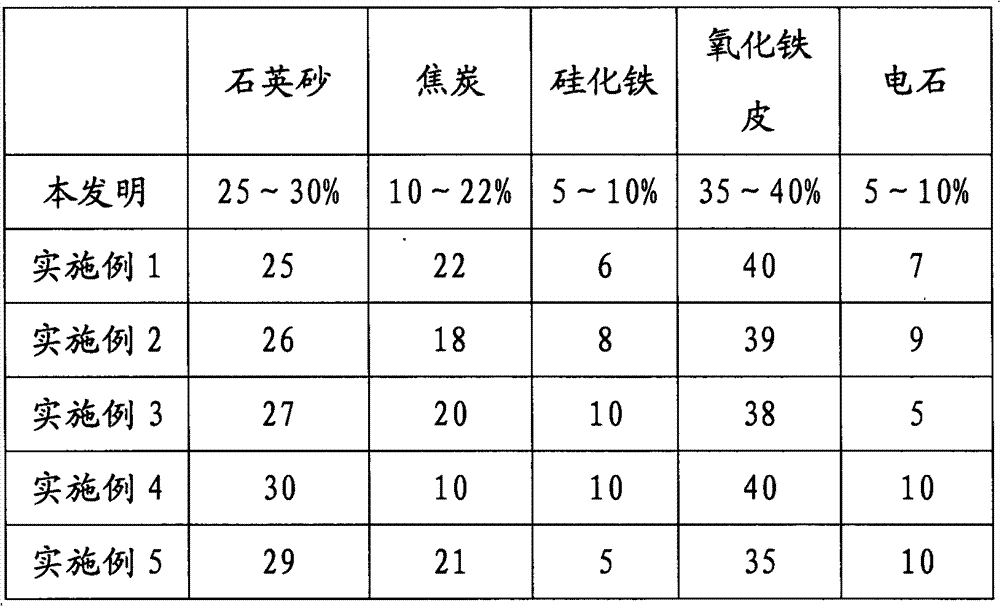

[0014] The heat-generating slagging agent for smelting low-silicon molten iron is made of iron silicide, quartz sand, coke, iron oxide scale, and calcium carbide, and its mass percentage is composed of: iron silicide: 5-10%, quartz sand 25-30%, coke 10-22 %, iron oxide scale 35-40%, calcium carbide: 5-10%. The mass percentage of chemical components after manufacture is: SiC: 41-46%; FeSi: 5-10%; FeO+Fe 2 o 3 : 35-40%; CaO: 0-6%; MgO: 0-3%, CaC 2 5-10%.

[0015] The silicon carbide in the above components is prepared in advance, which can be prepared by heating the mixture of quartz sand and coke with a mass percentage of 5:2 to about 1720°C in a vacuum state with an oxygen content preferably less than 0.2MPa, so that it can undergo a chemical reaction. Since quartz sand and coke usually contain impurities such as Ca and Mg, a small amount of impurities are solid-dissolved in the SiC produced. Among them, those with less impurities are green, and those with more impurities ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com