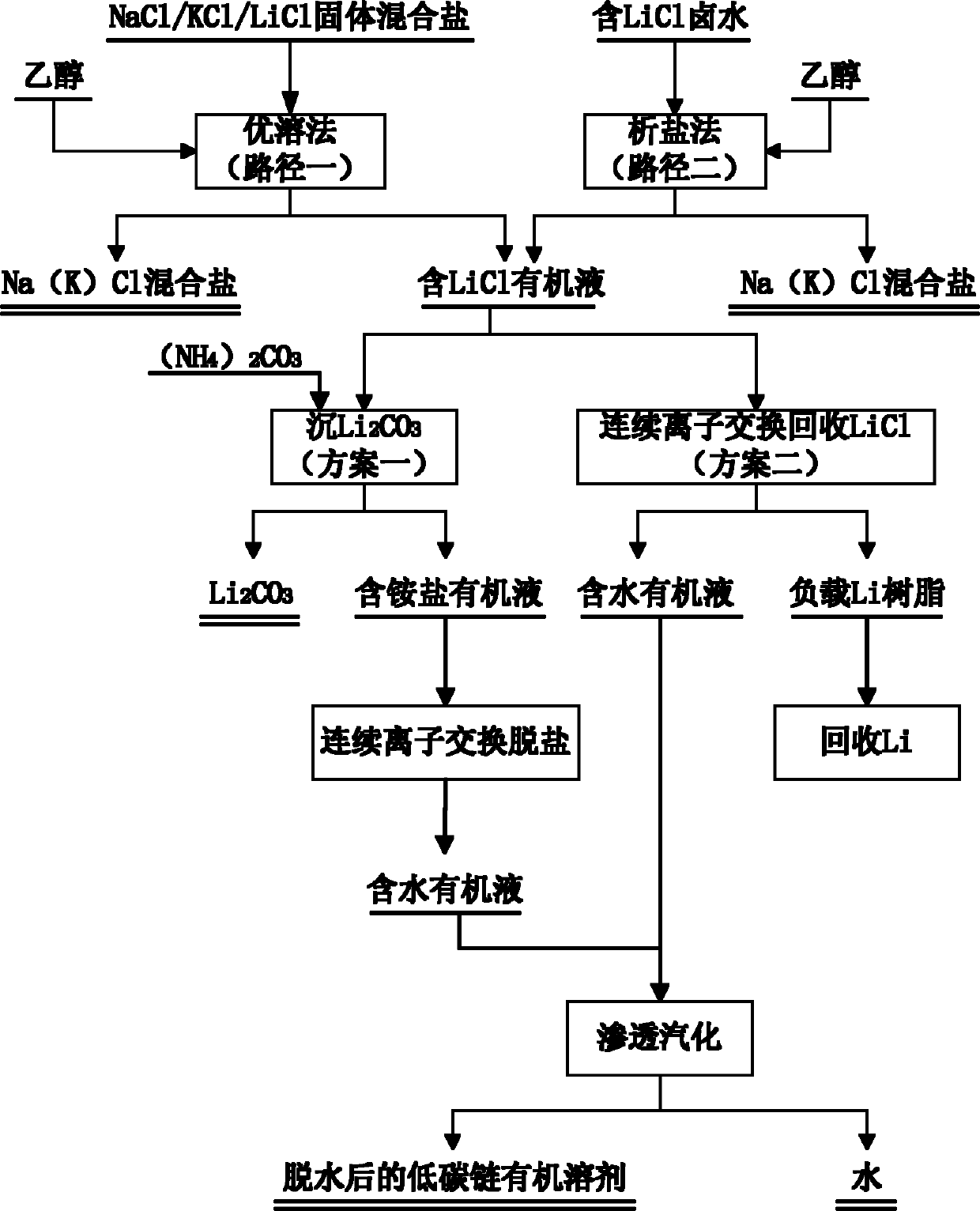

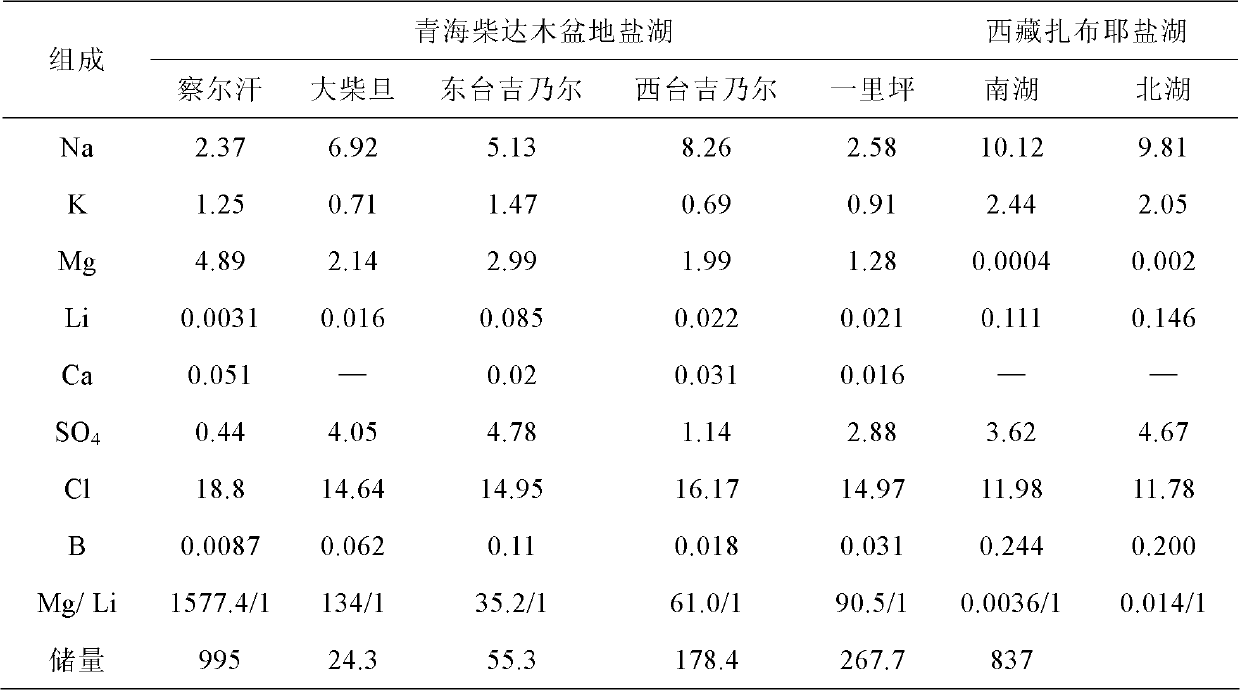

Process for extracting lithium from salt lake water subjected to calcium and magnesium preseparation

A salt lake water, pre-separation technology, applied in the direction of improving process efficiency, can solve problems such as high energy consumption, inability to carry out industrial application, and no proposal to recover acetone, etc., to achieve the effect of simple operation, reduced total cost, and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] LiCl 12.15g NaCl 38.15g KCl 63g prepared mixed salt, add ethanol 350ml, stir and leaching at room temperature for 1hr, the leaching rate of LiCl is 91%, NaCl and KCl are basically not leached, (the content of Na and K in the leaching solution cannot be detected by atomic absorption method ).

Embodiment 2

[0052] Take 220ml of saturated K(Na)Cl solution containing 1.98g of Li, add 350ml of ethanol, stir and mix, then place it in the net, a large amount of K(Na)Cl crystals are precipitated from the alcohol-water mixture, and the KCl precipitation rate reaches 81.85%. Dehydrated ethanol was washed twice, all LiCl remained in the mixed solution, and Li / K (molar ratio) increased from 0.34 in the stock solution to 1.87 in the mixed solution.

Embodiment 3

[0054] Contain Li 5.80g / L ethanol 200ml, add 35ml concentration and be 240g / L (NH 4 ) 2 CO 3 The solution is subjected to sedimentation. The first-order precipitation rate of Li is 80.67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance value | aaaaa | aaaaa |

| Conductance value | aaaaa | aaaaa |

| Ph value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com