Preparation technology for increasing effective photosensitive area of photoelectric material

A technology of photosensitive area and optoelectronic materials, applied in microlithography exposure equipment, circuits, electrical components, etc., can solve the problems of difficulty, restricting the development of solar cells, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

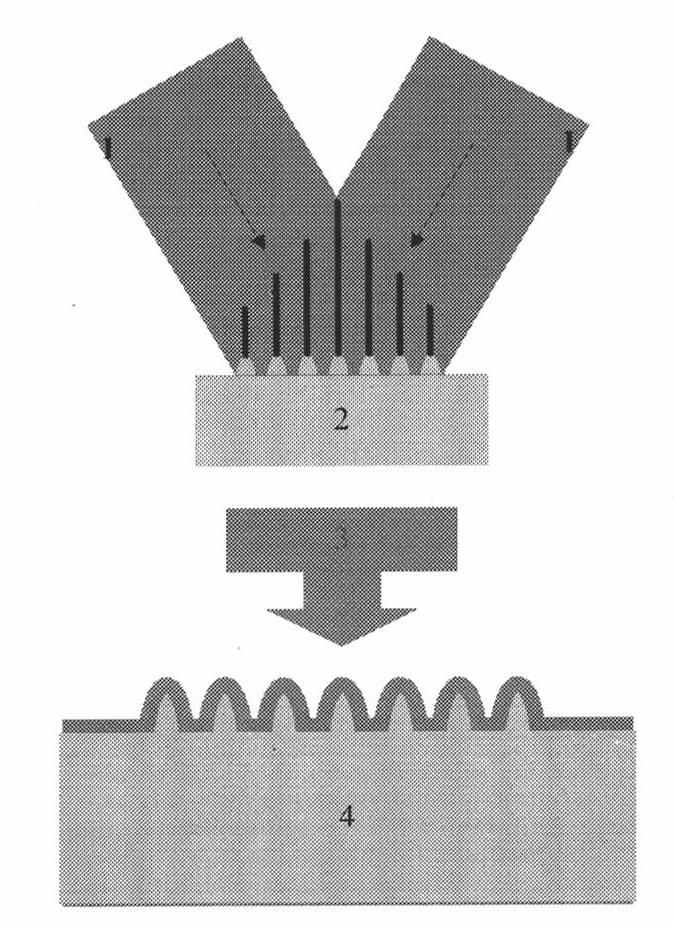

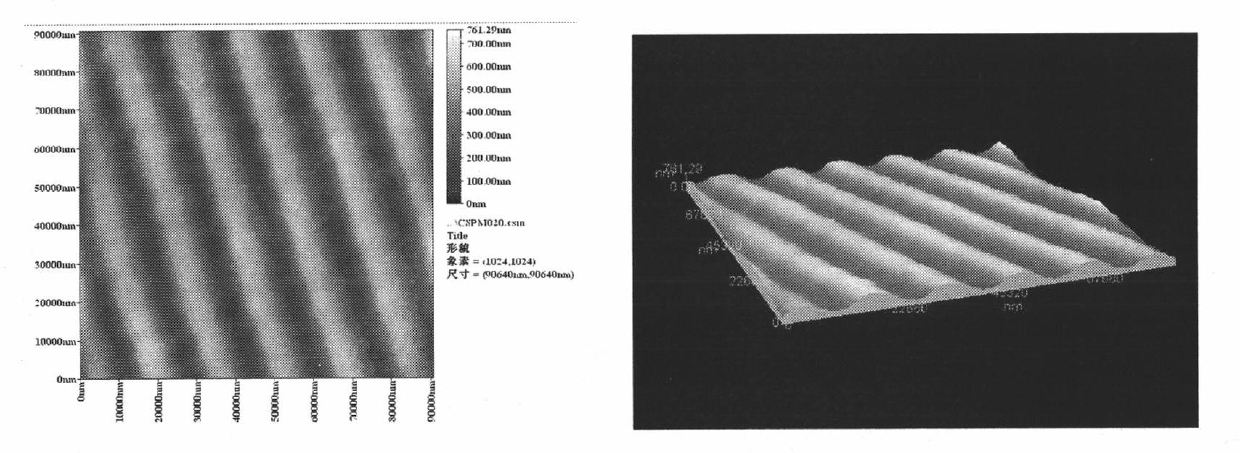

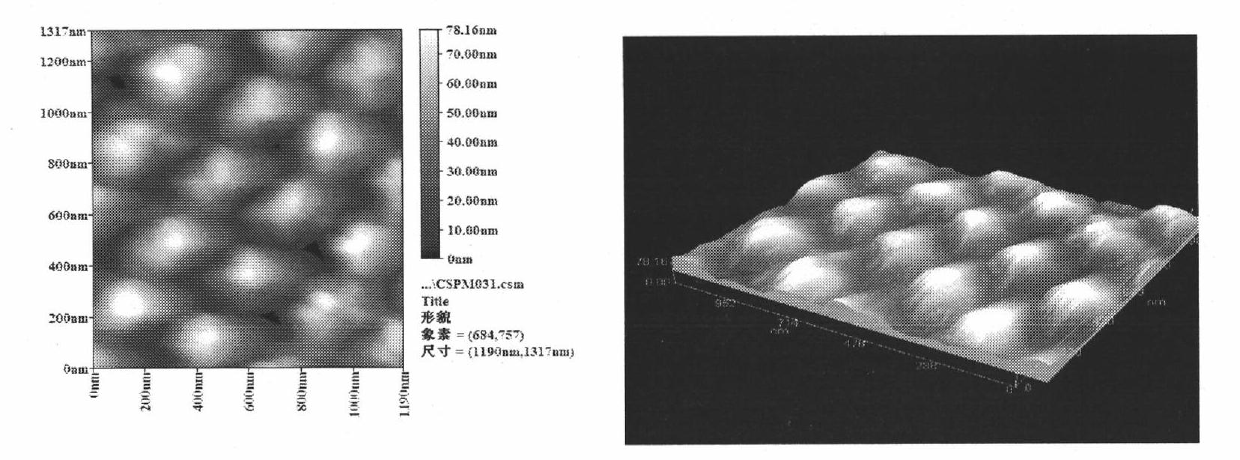

[0017] As shown in the figure, the present invention adopts the preparation technology of increasing the effective photosensitive area on the photoelectric material per unit size. Firstly, two beams of coherent light 1 in the laser interference lithography system are used to interfere on the surface of the substrate 2 material to obtain a micro-nano-scale periodic structure, and the structure is subjected to semiconductor doping treatment 3 to obtain a large surface area per unit size. Micro-Nano Periodic P-N Section Materials 4.

[0018] The above-mentioned laser interference exposure can be either two-beam single exposure to obtain a periodic grating structure, or double-beam double exposure or multi-beam exposure to obtain a three-dimensional columnar, spherical or depressed dot array. The characteristic size, period and pattern of the micro-nanostructure can be tuned by controlling the polarization and incident angle of the interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com