Nanocomposite phase-change material, preparation method and application thereof in phase-change memory

A phase change memory and phase change material technology, applied in nanotechnology, nanotechnology, metal material coating process, etc., can solve the problems of low carrier mobility, high threshold voltage, small dielectric constant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

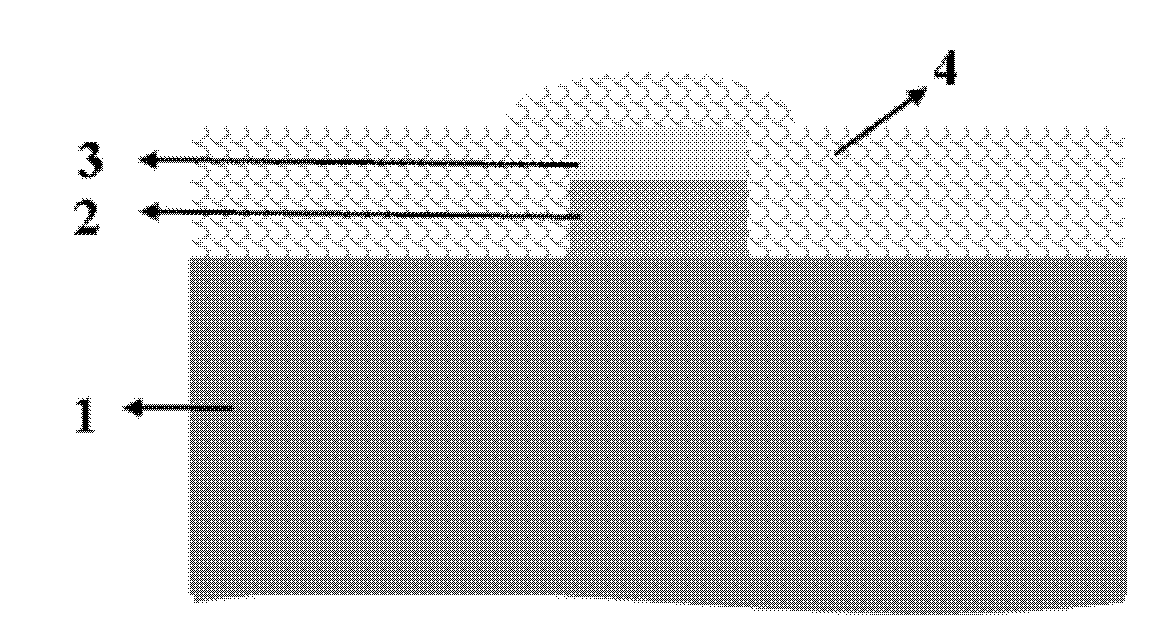

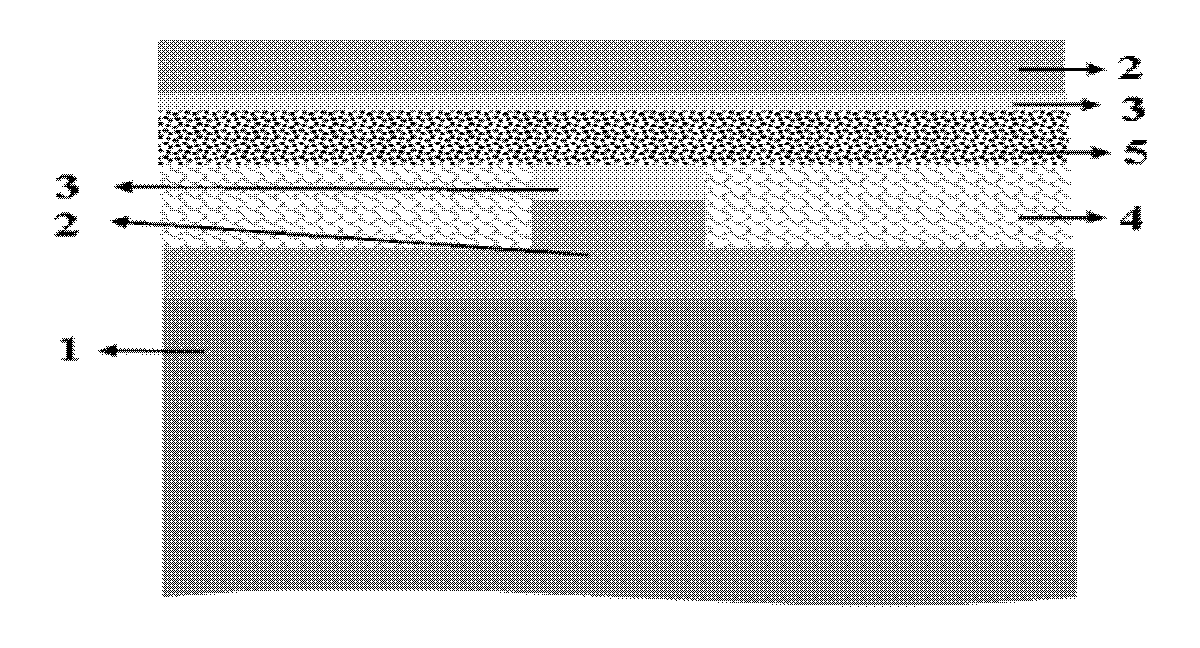

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The nanocomposite phase change material of the invention is composed of phase change material GeTe with a molar percentage of 70-99% and a dielectric material with a molar percentage of 1-30%. The dielectric material is HfO 2 , SiO 2 、TiO 2 、Si 3 N 4 or Ta 2 o 5 One or two or more of the above-mentioned dielectric materials are co-doped. For example, select the dielectric material as HfO 2 , wherein, in the nanocomposite phase change material, the phase change material GeTe and the dielectric material are uniformly dispersed in the composite material, and the phase change material GeTe is in the form of nanoscale particles with a maximum diameter of less than 100 nanometers. The preparation method of the nanocomposite phase change material can be prepared by semiconductor deposition process, such as any one of sputtering method, chemical vapor depositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com