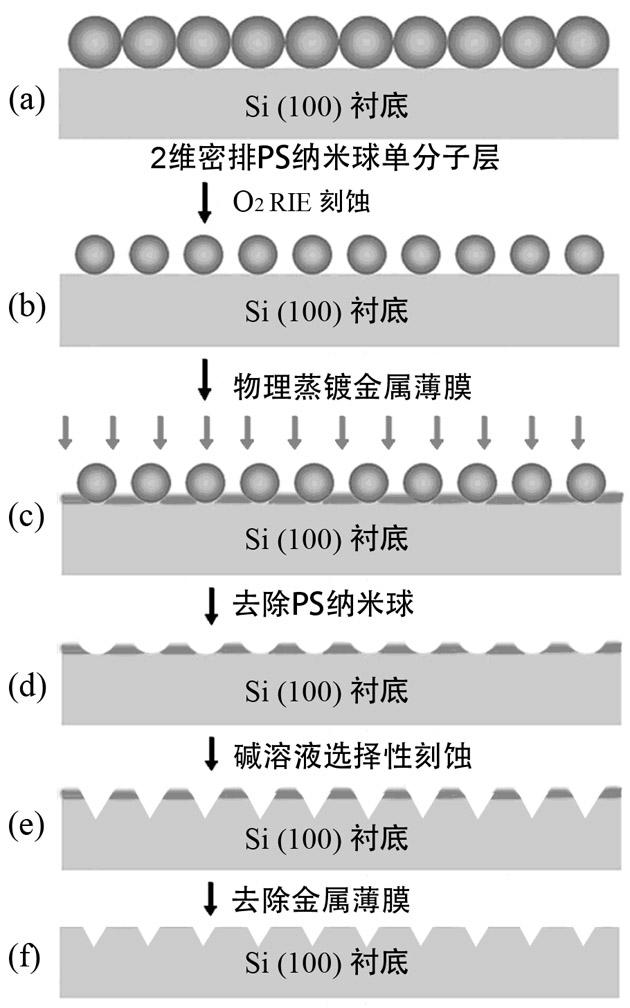

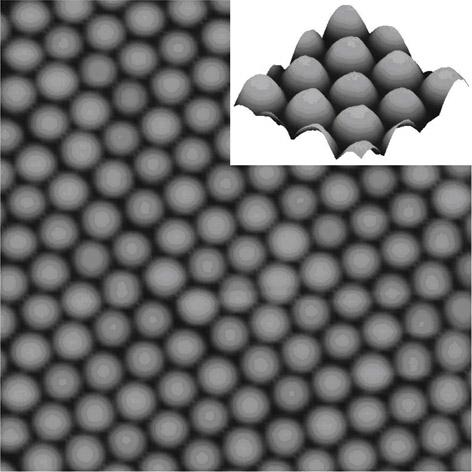

Preparation method for small silicon-based nano hollow array with orderly heights

A highly ordered, small-scale technology, used in the manufacture of microstructure devices, processes for producing decorative surface effects, decorative arts, etc. Easy operation control, highly ordered arrangement, low equipment price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. The substrate is Si(001) single wafer. Carry out the following cleaning treatment: rinse with deionized water for 2 minutes, sonicate with acetone for 5 minutes, and sonicate with methanol for 5 minutes. Rinse with deionized water for 5 minutes. in H 2 SO 4 :H 2 o 2 =2:1 After boiling the solution for 5 minutes, continue to soak for 5 minutes. After rinsing with deionized water for 3 minutes, put the ratio of HF:H 2 Dip in O=1:9 solution for 60 seconds to remove the oxide layer on the surface of the silicon wafer. Finally, after rinsing with deionized water for 60 seconds, spin dry with a spinner.

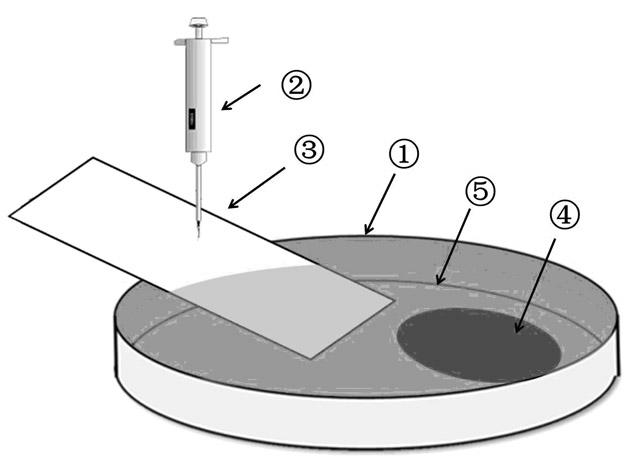

[0028] 2. To cover a single layer of polystyrene nanospheres on a silicon substrate, establish as figure 2 installation. The petri dish is made of polystyrene. The size is 100mm×20mm.

[0029] 3. will figure 2The slides used in the shown device were cleaned as follows: rinse with deionized water for 2 minutes, sonicate with acetone for 5 minutes, sonicate with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com