Deodorization method in treatment of printing and dyeing wastewater

One kind of printing and dyeing wastewater, another technology, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the limitation of soil deodorization method, increase the production and operation cost of enterprises, Increase the area of the project and other issues to shorten the sewage treatment time, improve the sewage plant and the surrounding environment, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

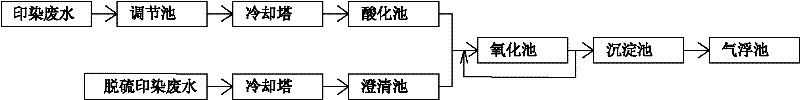

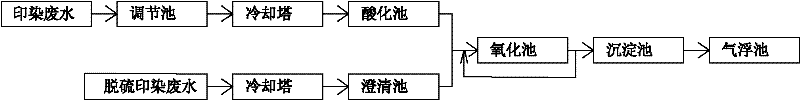

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of compound microbial bacterium liquid of the present invention is obtained after live bacteria, sugar black, water are mixed by weight 1: 0.5:160, sealed culture 5-7 days; Described another kind of compound microbial bacterium The liquid is obtained by mixing live bacteria, black sugar, salt, and water in a weight ratio of 18: 12: 0.5: 550, and culturing in a sealed manner for 5-7 days.

Embodiment 2

[0039] Embodiment 2: A kind of composite microbial bacterial liquid of the present invention is obtained after mixing live bacteria, sugar black, and water in a weight ratio of 3:1.5:120, and sealed for 5-7 days; The liquid is obtained by mixing live bacteria, black sugar, salt, and water in a weight ratio of 22:8:1.5:450, and culturing in a sealed manner for 5-7 days.

Embodiment 3

[0040] Embodiment 3: A kind of composite microbial bacterial liquid of the present invention is obtained after live bacteria, sugar black, water are mixed by weight ratio 2:1:140, sealed culture 5-7 days; Described another kind of composite microbial bacteria The liquid is obtained by mixing live bacteria, black sugar, salt, and water in a weight ratio of 20:10:1:500, and culturing in a sealed manner for 5-7 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com