Ferrite wave-absorbing material used for injection moulding, preparation method thereof and magnetic wave-absorbing element

A wave-absorbing material and injection molding technology, which is applied in ceramic molding machines, electrical components, manufacturing tools, etc., can solve the problems that wave-absorbing devices cannot be made into shapes, the scope of use is limited, and injection molding cannot be done, so that the crystal grains are arranged neatly , Guarantee the effect of free growth and complex shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides a ferrite absorbing material for injection molding, the molecular formula of the absorbing material is:

[0020] A 2 (B x +C 2-x )Fe 12 o 22

[0021] In the above molecular formula: A is Sr (strontium) or Ba (barium), B and C are Mn (manganese), Ni (nickel), Zn (zinc), Mg (magnesium), Co (cobalt), Cu (copper) or Any one of Ca (calcium), the value range of x is: 0≤x≤2.

[0022] The preparation method of the above-mentioned absorbing material is specifically:

[0023] The following raw materials are used, including:

[0024] Flux, can adopt any one in calcium oxide, magnesium oxide, bismuth oxide, strontium chloride, barium chloride;

[0025] Raw material one adopts any one in strontium carbonate or barium carbonate;

[0026] Raw materials 2 and 3 are manganese oxide, manganese carbonate, nickel oxide, nickel carbonate, zinc oxide, zinc carbonate, magnesium oxide, magnesium carbonate, cobalt oxide, cobalt carbonate, copper oxide, copper c...

Embodiment 2

[0039] This embodiment provides a microwave-absorbing material prepared in the prior art, specifically:

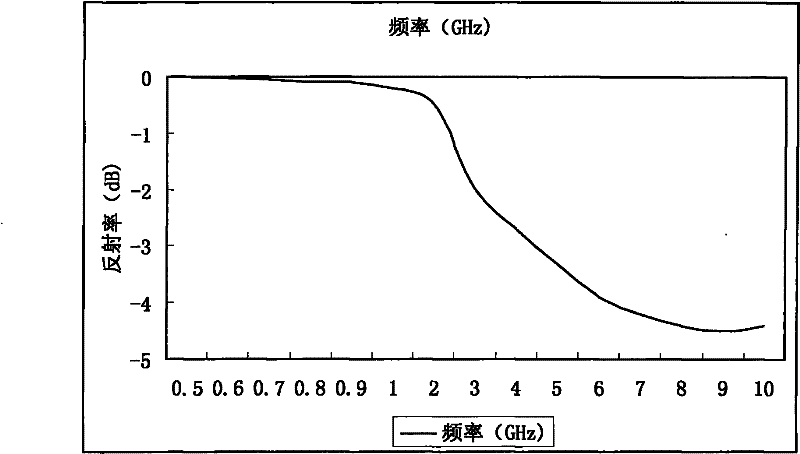

[0040] 0.1mol BaCO 3 powder, 0.07mol NiO powder, 0.03mol ZnO powder and 0.3mol Fe 2 o 3 Weigh the powder, put it into a ball mill for wet mixing for 5 hours (the ratio of ball to material is 10:1); add 0.1mol of flux, stir evenly, dry, dry press molding (molding pressure 1.5MPa); Heat preservation for 4 hours and pre-fire; break the pre-fired magnetic block into small pieces, and then put it into a ball mill for wet grinding for 1 hour (the ratio of ball to material is 10:1); wash, dry, and disperse to obtain absorbent powder; Through the injection process, the required magnet wave absorbing device is made. The electromagnetic wave reflectivity curve of the wave-absorbing material that this comparison example 2 makes sees attached figure 1 ,from figure 1 It can be seen that there is a peak at 9GHz, and the reflectivity is -4.5dB, which has good absorbing performance. ...

Embodiment 3

[0042] This embodiment provides a microwave-absorbing material prepared in the prior art, specifically:

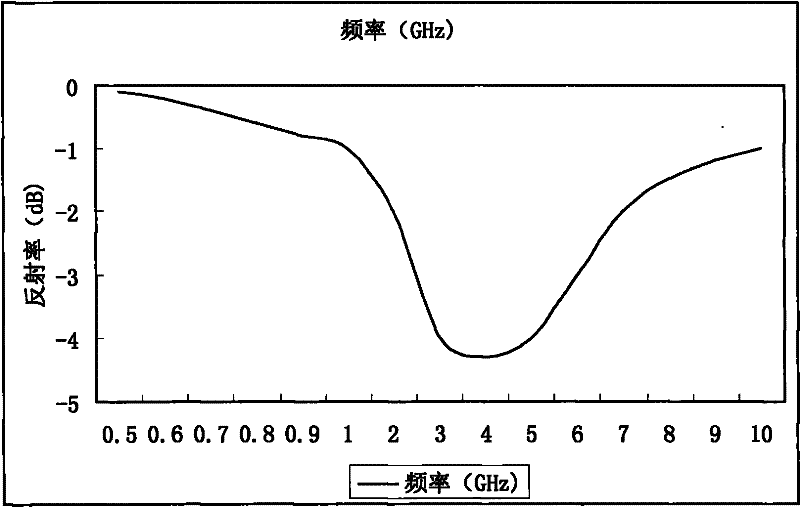

[0043] 0.1mol SrCO 3 powder, 0.07mol MgO powder, 0.03mol ZnO powder and 0.3mol Fe 2 o 3 Weigh the powder, put it into a ball mill for wet mixing for 3 hours (the ratio of ball to material is 10:1); add 0.2 mol of flux, stir evenly, dry, dry press molding (molding pressure 1.5MPa); Heat preservation for 4 hours and pre-fire; break the pre-fired magnetic block into small pieces, and then put it into a ball mill for wet grinding for 1 hour (the ratio of ball to material is 10:1); wash, dry, and disperse to obtain absorbent powder; Through the injection process, the required magnet wave absorbing device is made. The electromagnetic wave reflectivity curve of the wave-absorbing material that this comparison example 2 makes sees attached figure 2 ,from figure 2 It can be seen that there is a peak at 4GHz, and the reflectivity is -4.3dB, which has good absorbing performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com