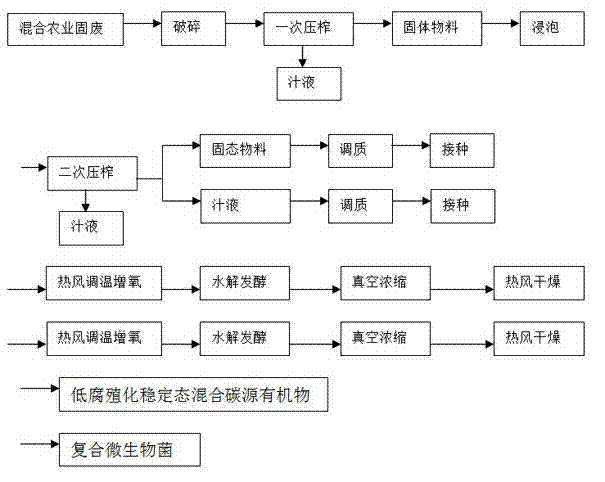

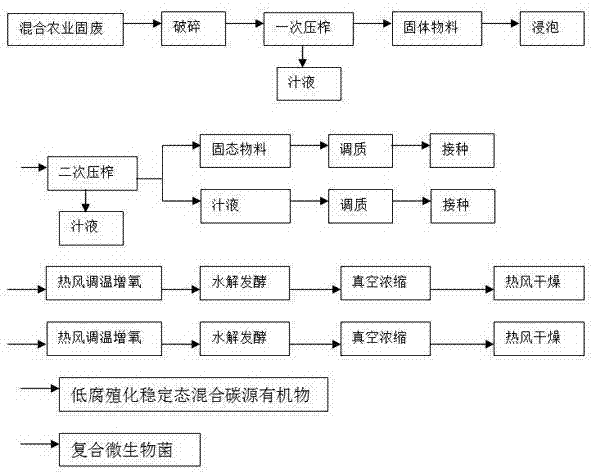

Method for treating and utilizing agricultural solid waste through aerobic high-temperature hydrolysis and fermentation

A high-temperature hydrolysis and agricultural technology, applied in agriculture, bio-organic part treatment, application, etc., can solve environmental disasters, improper disposal and other problems, and achieve the effects of environmental protection and safety in the production process, optimal adjustment and control, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for treating and utilizing agricultural solid waste by aerobic high-temperature hydrolysis and fermentation. The sheared and crushed crop straw is mixed with livestock and poultry manure at a weight ratio of 1:6, and the liquid and solid components in the mixture are separated by pressing, and the solid residue obtained by pressing is soaked Squeeze again to separate the liquid and solid components; after mixing the squeezed juice obtained in the previous step twice, adjust the pH with acetic acid or lime water, the pH range is 4.5, and inoculate 0.1% activated sludge of the weight of the squeezed mixed juice (activated sludge takes Sludge from the aerobic pool of the urban sewage treatment plant), the mixed juice is hydrolyzed and fermented under the condition of hot air at 40°C, the internal temperature of the liquid is controlled at 30°C, the fermentation cycle is 1 day, and then vacuum concentrated and cooled to obtain the compound microbial bacterial agent p...

Embodiment 2

[0027] A method for treating and utilizing agricultural solid waste by aerobic high-temperature hydrolysis and fermentation. The sheared and crushed crop straw is mixed with livestock and poultry manure at a weight ratio of 5:2, and the liquid and solid components in the mixture are separated by pressing, and the solid residue obtained by pressing is soaked Squeeze again to separate the liquid and solid components; after mixing the squeezed juice obtained in the previous step twice, adjust the pH with acetic acid or lime water, the pH range is 8.5, and inoculate 0.5% activated sludge of the weight of the squeezed mixed juice (activated sludge takes Sludge from the aerobic pool of the urban sewage treatment plant), the mixed juice is hydrolyzed and fermented under the condition of hot air at 70°C, the internal temperature of the liquid is controlled at 60°C, the fermentation cycle is 10 days, and then vacuum concentrated and cooled to obtain the compound microbial bacterial agent...

Embodiment 3

[0029]A method for treating and utilizing agricultural solid waste by aerobic high-temperature hydrolysis and fermentation. The sheared and pulverized crop straw is mixed with livestock and poultry manure at a weight ratio of 1:1, the liquid and solid components in the mixture are separated by pressing, and the solid residue obtained by pressing is soaked Squeeze again to separate the liquid and solid components; after mixing the squeezed juice obtained in the previous step twice, adjust the pH with acetic acid or lime water, the pH range is 7.5, and inoculate 0.2% activated sludge of the weight of the squeezed mixed juice (activated sludge takes Sludge from the aerobic pool of the urban sewage treatment plant), the mixed juice is hydrolyzed and fermented under the condition of hot air at 55°C, the internal temperature of the liquid is controlled at 40°C, the fermentation period is 1-10 days, and then vacuum concentrated and cooled to obtain a compound microbial agent Product: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com