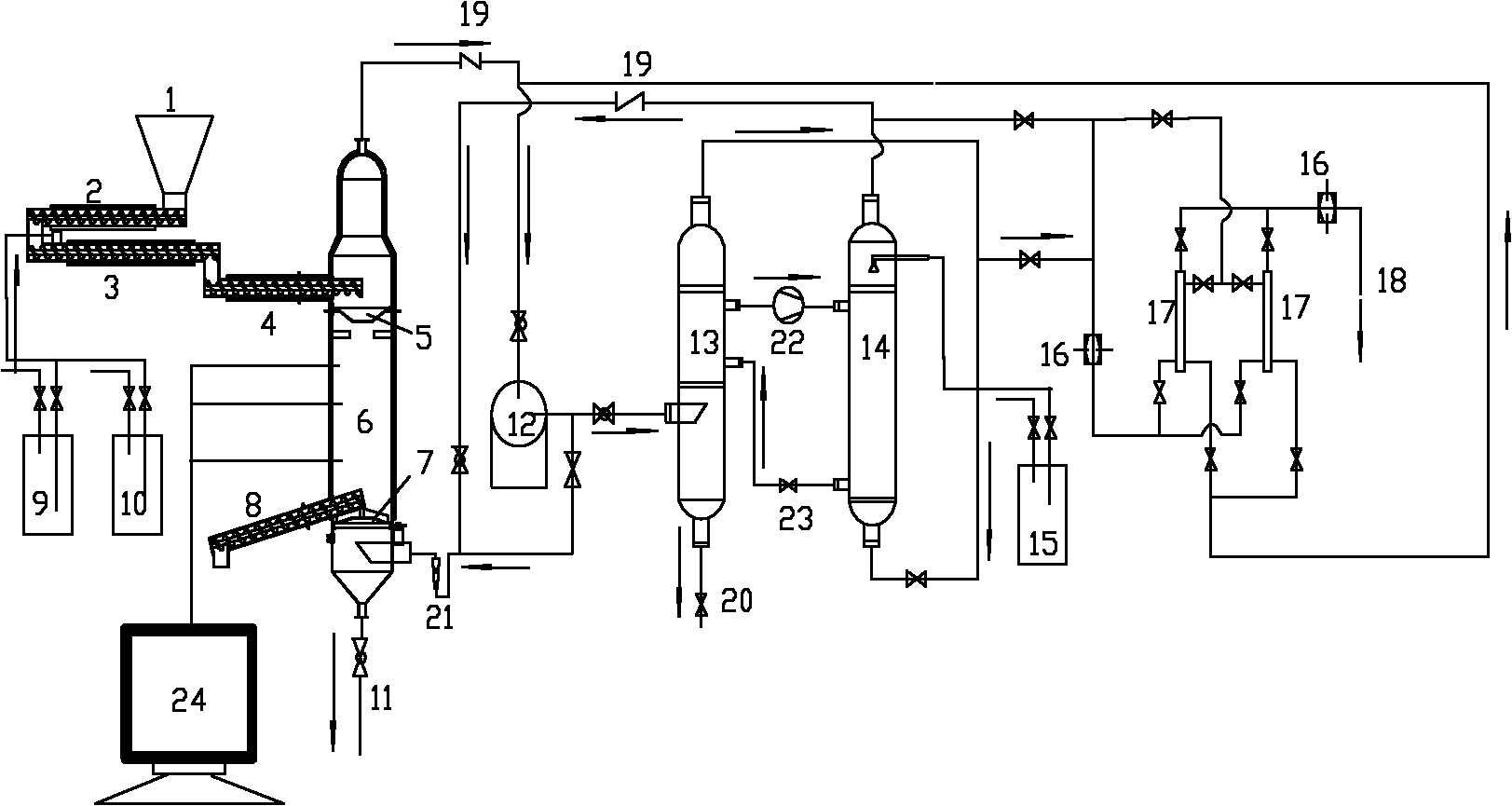

Continuous solid state fermentation and product gas stripping coupled separation method for corn

A technology of solid-state fermentation and product gas, which is applied in the field of corn deep processing, can solve problems such as difficult to achieve continuous solid-state fermentation, and achieve the effects of saving water consumption, increasing porosity, and improving gas circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Corn steam explosion pretreatment: put soaked corn (more than 35% water content) into the steam explosion equipment, maintain 5min under the saturated steam pressure of 1.25MPa, release the pressure instantly, and collect the steam explosion raw materials;

[0032] (2) Mixed fermentation of steam-exploded corn and dry corn grains for ethanol: steam-exploded corn and dry corn grains were mixed according to the dry weight of 2:1, fed through a screw conveyor, and glucoamylase (65U / g substrate) was inoculated at the same time. Qi high active dry yeast Saccharomyces cerevisiae (inoculum size 0.5% (v / v)), and add nutrient salt (0.1% (NH4) 2 SO 4 , 0.1% KH 2 PO 4 ), adjust the pH to be about 5.0, and use CO 2 Replace the air in the system, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 35°C, the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, the fermentation time was 60h, final...

Embodiment 2

[0036] (1) Corn steam explosion pretreatment: put soaked corn (more than 35% water content) into the steam explosion equipment, maintain 5min under the saturated steam pressure of 1.25MPa, release the pressure instantly, and collect the steam explosion raw materials;

[0037] (2) Mixed fermentation of butanol with steam-exploded corn and dry corn kernels: steam-exploded corn and dry corn kernels are mixed according to the dry weight 1:1, fed through a screw conveyor, and 10% (v / v) Clostridium acetobutylicumATCC is added at the same time 824 seed medium, adjust the pH to 6.5, and use CO after feeding 2 Replace the air in the system, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 37°C, the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, fermentation time 72h, the total solvent yield obtained is 19.5g / L, wherein the butanol output is 13.65g / L, the ethanol output is 3.9g / L, and the acetone o...

Embodiment 3

[0041] (1) Corn steam explosion pretreatment: put soaked corn (more than 35% water content) into the steam explosion equipment, maintain 5min under the saturated steam pressure of 1.25MPa, release the pressure instantly, and collect the steam explosion raw materials;

[0042] (2) Mixed fermentation of butanol with steam-exploded corn and dry corn kernels: steam-exploded corn and dry corn kernels are mixed according to dry weight 3:1, fed through a screw conveyor, and 10% (v / v) Clostridium acetobutylicumATCC is added at the same time 824 seed medium, adjust the pH to 6.5, and use CO after feeding 2 Replace the air in the system, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 37°C, the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, the fermentation time was 72h, and the total solvent yield obtained was 17.8g / L, wherein the butanol output was 17.8g / L, the ethanol output was 3.56g / L, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com