Preparation method of gardenia red pigment

A gardenia red and pigment technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of high production cost of gardenia red pigment, unfavorable industrial production, and inability to separate and recycle enzymes, and achieve production Continuity, good water solubility, and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

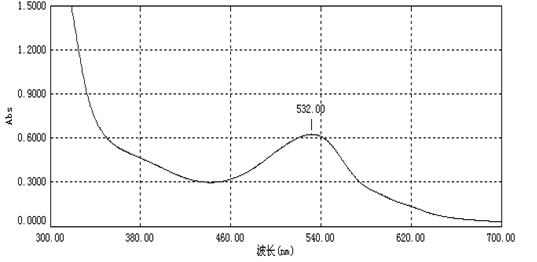

Image

Examples

preparation example Construction

[0034] Adsorption of the present invention has the preparation of the resin of geniposide, and the steps are as follows:

[0035] Grind the fruit of Gardenia jasminoides, soak it in water or extract it under reflux for 1 to 3 times, and filter to obtain the extract of gardenia yellow pigment; pump the extract of gardenia yellow pigment into a container filled with resin (such as glass column, stainless steel container , enamel column, etc.) for adsorption, the saturated resin is desorbed by 30% to 100% ethanol aqueous solution, the mass volume ratio of resin to ethanol aqueous solution is 1:3, desorbed at 15°C to 55°C, only a small amount of gardenia remains in the resin Yellow pigment, the desorption solution is used to prepare gardenia yellow pigment, and the desorbed resin is the resin with geniposide adsorbed.

Embodiment 1

[0038] Pump 200ml of 0.5mol / L sodium hydroxide solution into the container with adsorbed geniposide resin, control the reaction temperature at about 20°C, circulate alkali hydrolysis for 7 hours, and circulate the flow rate at 3BV / h. After the reaction, the lye was discarded, and the citric acid solution of 5 mol / L was pumped into the container to react until the pH value of the solution was 6.0, and the circulation flow rate was 6 BV / h. After acidification, discard the acidification solution, pump 100ml of 0.1u / mL (according to the enzyme activity unit) cellulase solution into the container, control the reaction temperature at about 70°C, and circulate the enzymolysis for 0.5h with a circulation flow rate of 5BV / h . After the enzymatic hydrolysis, discard the enzyme solution, then pump 100ml of 20% glutamic acid solution into the container, control the reaction temperature at about 20°C, and circulate the reaction for 9 hours with a circulation flow rate of 7BV / h to obtain th...

Embodiment 2

[0040]Pump 300ml of 3.0mol / L potassium hydroxide solution into the container with adsorbed geniposide resin, control the reaction temperature at about 70°C, circulate alkali hydrolysis for 6h, and circulate at a flow rate of 6BV / h. After the reaction, the lye was discarded, and the 4.5mol / L tartaric acid solution was pumped into the container to react until the pH value of the solution was 4.0, and the circulation flow rate was 3BV / h. After acidification, discard the acidification solution, pump 150ml of 2.0 u / mL (according to enzyme activity unit) pectin enzyme solution into the container, control the reaction temperature at about 40°C, and circulate enzymatic hydrolysis for 9 hours at a circulation flow rate of 5BV / h. After the enzymatic hydrolysis, the enzyme solution was discarded, and then 190ml of 13% galactosamine solution was pumped into the container, the reaction temperature was controlled at about 46°C, the reaction was circulated for 25 hours, and the circulation fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com