Method for measuring content of 1,3-dioleoyl-2-palmitoyl triglyceride in dairy products

A technology for triglyceride palmitate and dairy products, which is applied in the field of analytical chemistry, can solve problems such as inaccurate determination of OPO addition, and achieve the effect of low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

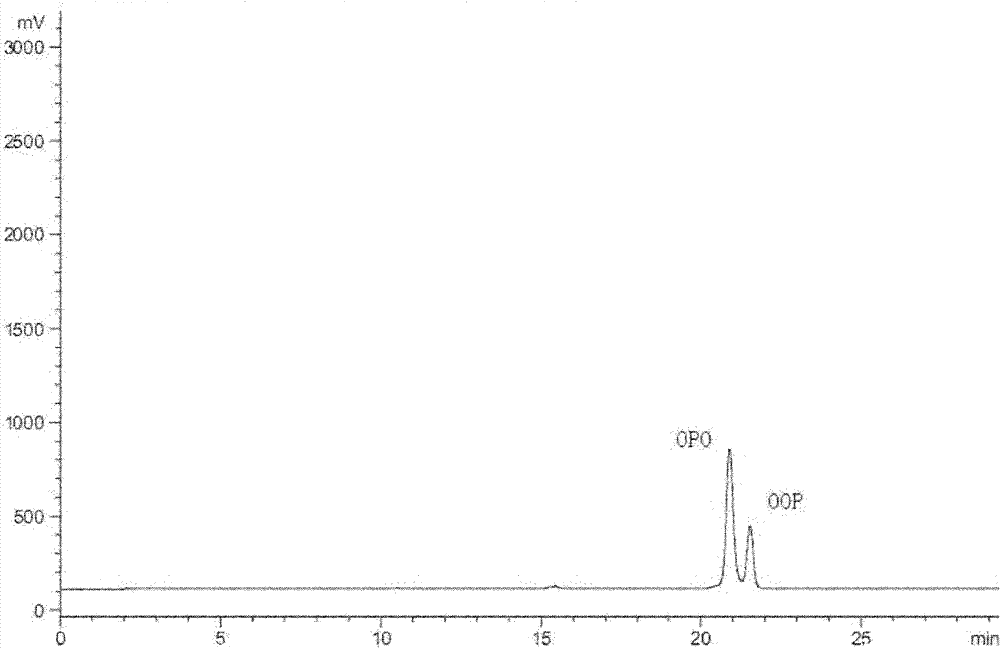

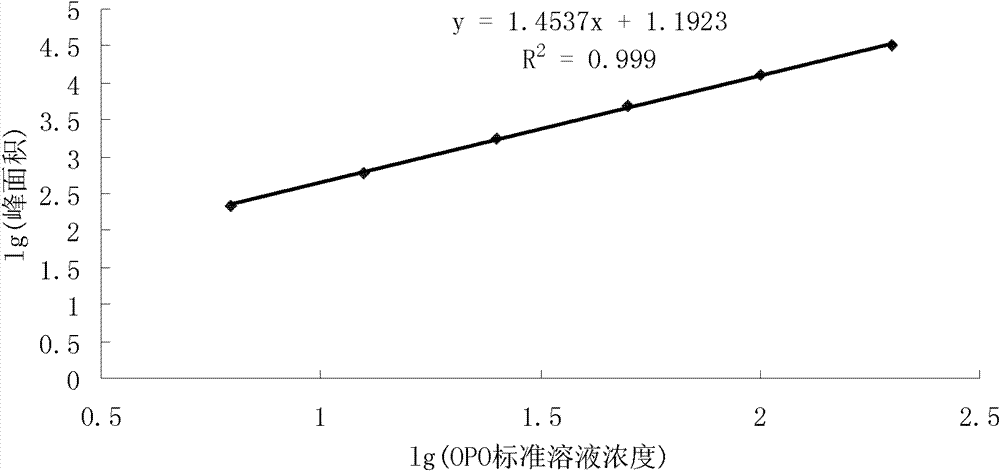

[0040] Example 1: Determination of OPO content in infant milk powder.

[0041]Weigh 1.0g (accurate to 0.1mg) of infant milk powder sample (French Synbiotics) into a liposuction tube, add 10mL of water at 65±1°C to dissolve the sample, and shake to completely disperse the sample. Add 2mL of ammonia water to the sample, place it in a water bath at 65±1°C for 15min, take it out and shake it gently, and cool to room temperature. Add 10 mL of ethanol to the prepared sample and mix well. Add 25mL of diethyl ether, stopper and shake for 1min, add 25mL of petroleum ether, stopper and shake for 1min, let stand, separate layers, and transfer the organic layer into a ground-necked flask. Then add 25mL diethyl ether and 25mL petroleum ether, stopper and shake for 1min, let stand, separate layers, transfer the organic layer into a ground-necked flask, and repeat the extraction operation once more. Combine the organic layers in a ground flask, and concentrate to dryness at 55°C with a rot...

Embodiment 2

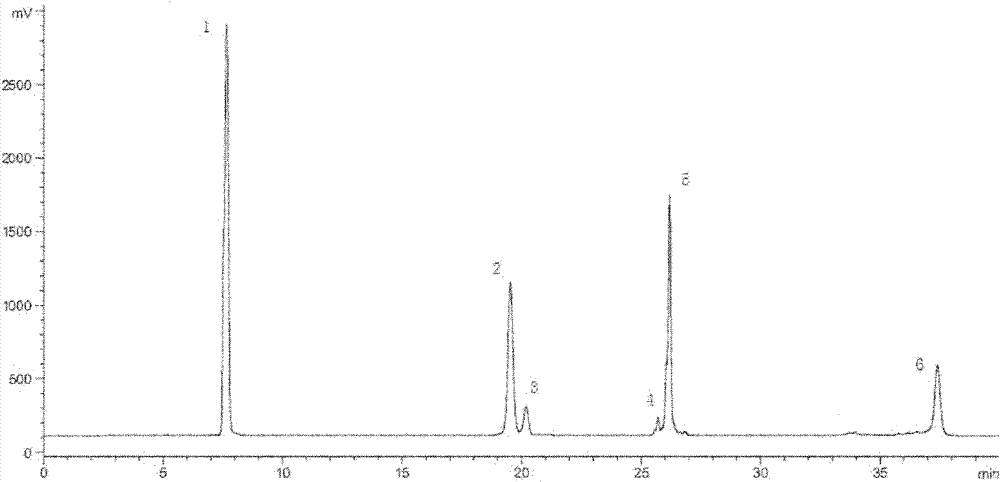

[0066] Embodiment 2: the content determination of OPO in the rice flour.

[0067] Weigh 1.0g of rice flour (accurate to 0.1mg) into a liposuction tube, add 0.1g of peak-type amylase, add 10mL of 50°C water, cover the bottle, place in a 40°C oven for 30min, and cool to room temperature. Add 10 mL of ethanol to the prepared sample, mix well, add 20 mL of diethyl ether, stopper and shake for 1 min, add 20 mL of petroleum ether, stopper and shake for 1 min, let stand, separate layers, and transfer the organic layer into a ground-necked flask. Then add 5 mL of ethanol, 20 mL of diethyl ether and 20 mL of petroleum ether, stopper and shake for 1 min, let stand, separate layers, transfer the organic layer into a ground-necked flask, and repeat the extraction operation once. Combine the organic layers in a ground flask, and concentrate to dryness at 50°C with a rotary evaporator. dichloromethane was diluted to 200mL to obtain a fat solution.

[0068] The fat solution obtained above ...

Embodiment 3

[0083] Example 3: Verification of the recovery rate of OPO in infant milk powder.

[0084] Weigh 1.0g (accurate to 0.1mg) of the two infant milk powder samples into liposuction tubes, add 1-100mg of OPO standard, 10mL of water at 65±1°C to dissolve the samples, and shake to completely disperse the samples . Add 2mL of ammonia water to the sample, place it in a water bath at 65±1°C for 15min, take it out and shake it gently, and cool to room temperature. Add 10 mL of ethanol to the prepared sample, mix well, add 30 mL of diethyl ether, stopper and shake for 1 min, add 30 mL of petroleum ether, stopper and shake for 1 min, let stand, separate layers, and transfer the organic layer into a ground-necked flask. Then add 30mL diethyl ether and 30mL petroleum ether, stopper and shake for 1min, let stand, separate layers, and transfer the organic layer into a ground-necked flask. The combined extracts were placed in a ground-necked flask, and concentrated to dryness at 60°C by a rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com