Multi-beam laser heterodyne distance measurement device and method for measuring young modulus by adopting device

A technology of laser heterodyne and distance measurement, which is applied in the field of testing, can solve the problem of a single parameter value to be measured, and achieve the effect of fast measurement speed, convenient operation and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

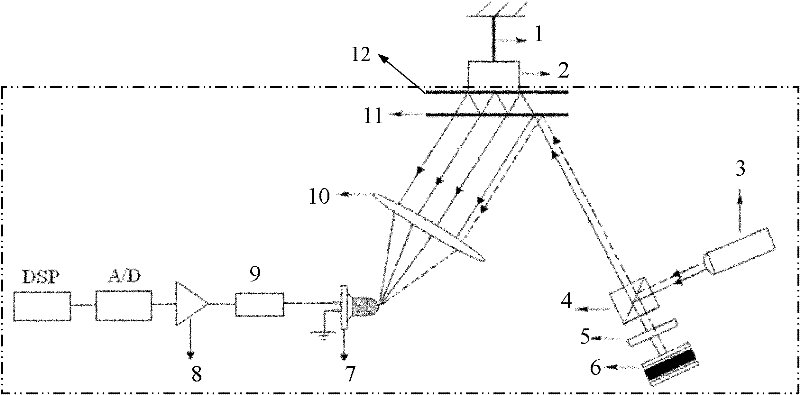

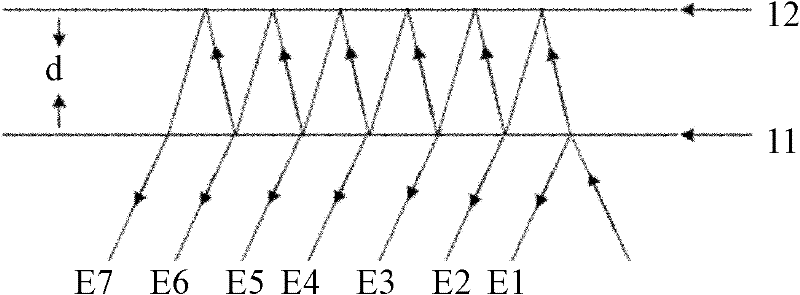

[0023] Embodiment 1. The device for measuring distance by multi-beam laser heterodyne described in this embodiment is composed of H 0 Composition of solid-state laser 3, plane mirror 12, quarter-wave plate 5, galvanometer 6, galvanometer driving power supply, polarizing beam splitter 4, converging lens 10, thin glass plate 11, photodetector 7 and signal processing system , the vibrating mirror drive power supply is used to drive the vibrating mirror 6 to vibrate; the thin glass plate 11 is in a fixed position, and a plane reflector 12 is set on one side of the thin glass plate 11 at a distance d, and the distance between the thin glass plate 11 and the plane reflector 12 The reflective surfaces are opposite and parallel to each other, H 0 The solid-state laser 3, the quarter-wave plate 5, the vibrating mirror 6, the polarizing beam splitter 4, the converging lens 10, and the photodetector 7 are all located under the thin glass plate 11, and the H 0 The solid-state laser 3 emi...

specific Embodiment approach 2

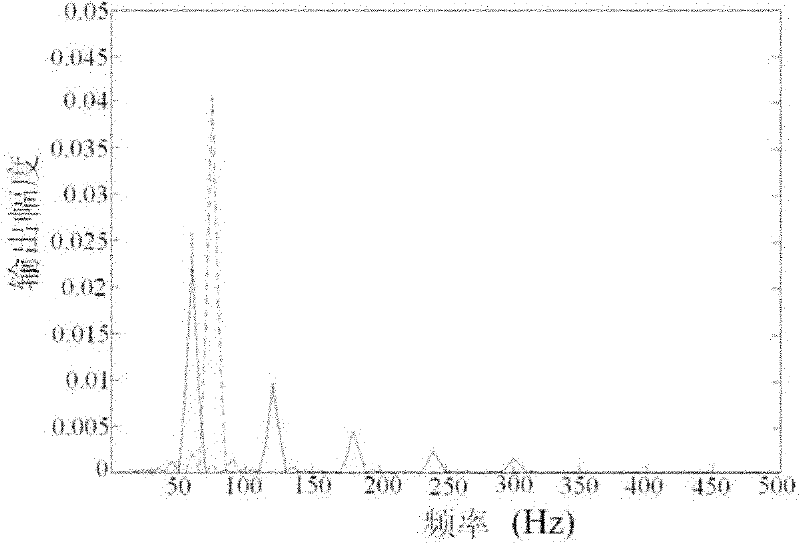

[0039] Specific embodiment two, described in this embodiment is to adopt the device for measuring Young's modulus of the multi-beam laser heterodyne described in specific embodiment one to realize the method for measuring Young's modulus, and the process of this method is:

[0040] Step 1. Hang a metal wire to be tested with a length L and an average diameter of r on a fixed support, and the lower end is fixedly connected with a weight. Under the action of the weight itself, the weight exerts a pulling force F on the steel wire to be tested. To make the steel wire generate internal stress; the bottom of the weight is fixedly connected to the bottom surface of the plane mirror 12, and then the laser is turned on;

[0041] Step 2, the signal processing system collects the signal output by the photodetector 7, and obtains a distance parameter, and records the distance parameter when the plane reflector 12 is in a static state;

[0042] Step 3, increase the quality m of the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com