Method for purifying tail gas of flue gas carbon dioxide collecting system through rotating flow and device thereof

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, separation methods, climate sustainability, etc., can solve problems such as uneconomical, economic benefit impact, and increased operating costs, so as to reduce emissions and avoid entrainment Damage and prevention of atmospheric environment hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

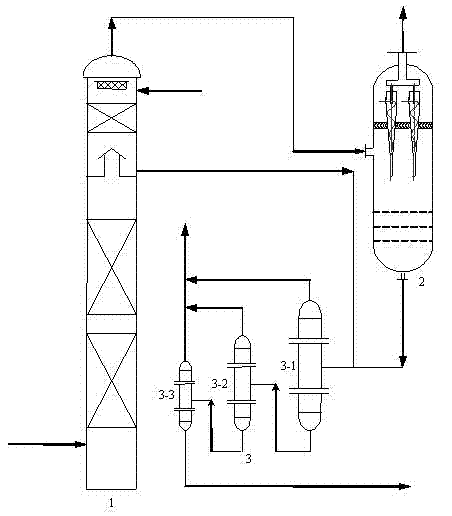

[0028] Such as figure 1 As shown, the absorption tower 1 located at the forefront of the device is used to absorb and capture the carbon dioxide components in the flue gas, and remove the gas components such as sulfur dioxide and nitrogen oxides entrained in the tail gas.

[0029] The ultra-low pressure drop swirl flow separator 2 connected to the tail gas outlet at the top of the absorption tower 1 is used for swirl flow separation and recovery of aerosol particles entrained in the tail gas.

[0030] The liquid-solid micro-swirl flow separator group 3 connected to the wash liquid outlet of the ultra-low pressure drop swirl flow separator 2 and the wash liquid outlet of the absorption tower 1 is used for swirl flow separation of solid particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com