Chiral zinc complex secondary structure hollow microsphere and preparation method thereof

A technology of zinc complexes and hollow microspheres, which is applied in the direction of zinc organic compounds, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as limitations, and achieve regular morphology and high ratio Surface area, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

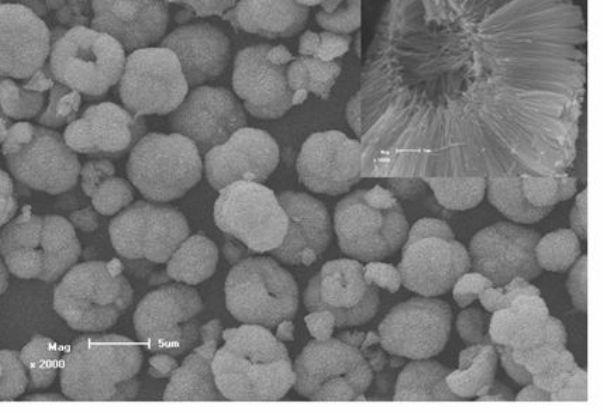

[0021] The present invention uses zinc acetate (Zn(CH 3 COO) 2 ?2H 2 O) and 2,4-tetrahydrothiazole diacid (H 2 L) is a raw material, using water as a solvent, polyvinylpyrrolidone (PVP) as a surfactant, and acetone as a precipitating agent, all of which are commercially available products without any treatment before use. The preparation steps are as follows:

[0022] 1) Add 0.44 g Zn(CH 3 COO) 2 ?2H 2 After O and 11.20 g PVP are mixed, be dispersed in 160.0 g water and make mixed solution, its mass ratio is 1: 25.5: 363.6;

[0023] 2) Add a concentration of 50 mmol / L H 2 O of H 2 Add 40.0 ml of L aqueous solution to the above mixture, stir at room temperature for 2 hours, and stand at 80°C for 6 hours;

[0024] 3) A white precipitate appeared after adding acetone, and the precipitate obtained by centrifugation was washed 10 times with absolute ethanol to obtain a white powder, which was the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com