Polyether polyurethane elastomer toughened polylactic acid alloy and preparation method thereof

A polyether polyurethane and elastomer technology is applied in the field of polyether polyurethane elastomer toughening polylactic acid alloy and its preparation, which can solve the problems of poor interfacial bonding strength, fracture, poor compatibility, etc. Easy to control, high strength and modulus, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dehydrate 12.0 g (0.012 mol) of polyethylene glycol (number average molecular weight: 1000, hydroxyl value: 118 mgKOH / g) at 120° C. and 180 Pa for 1 hour to obtain dehydrated polyethylene glycol.

[0040] In a drying reactor connected with a thermometer, a stirring paddle, a condensing tube and a gas inlet and outlet, the dehydrated polyethylene glycol is heated to 80° C., and 5.4414 g (0.0245 mol) of isophorone diisocyanate is added under nitrogen protection. The catalyst dibutyltin dilaurate that accounts for polyethylene glycol mass 0.5% carries out polymerization reaction, reacts 30min, obtains the prepolymer of isophorone diisocyanate termination; Prepolymer and 1.0814g (0.012mol) are subjected to vacuum distillation The treated small molecule diol chain extender 1,4-butanediol and 40mL solvent N,N'-dimethylformamide were subjected to chain extension reaction at 100°C for 12h, and the product was dried in a vacuum oven at 100°C to obtain a colorless Transparent, hi...

Embodiment 2

[0044] The polyurethane elastomer was prepared according to the preparation steps of the polyurethane elastomer in Example 1.

[0045] Except that the mass parts of polyurethane elastomer are 10 and the mass parts of polylactic acid are 90 (the number average molecular weight of polylactic acid is 100000), all the other operations are the same as in Example 1 to prepare polylactic acid / polyurethane alloy.

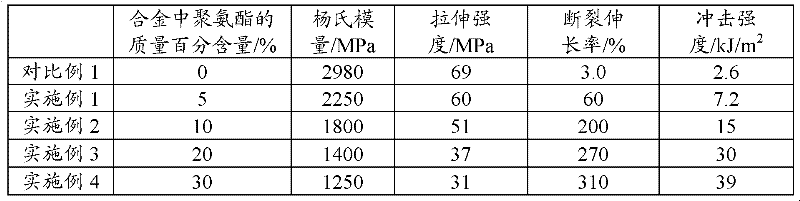

[0046] The polylactic acid / polyurethane alloy was injection molded to obtain a standard test sample, and the mechanical properties of the polylactic acid alloy were shown in Table 1.

Embodiment 3~4

[0048] Except that the mass parts of polyurethane elastomer are respectively 20,30 and the mass parts of polylactic acid are respectively 80,70 (the number average molecular weight of polylactic acid is 100000), all the other operations are the same as embodiment 1, make polylactic acid / polyurethane alloy.

[0049] The polylactic acid / polyurethane alloy was injection molded to obtain a standard test sample, and the mechanical properties of the polylactic acid alloy were shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com