Method for improving yield of L-threonine produced by fermentation

A threonine yield and fermenter technology, which is applied in the field of improving the yield of L-threonine by fermentation, can solve the problems of high equipment investment and production and operation costs, and achieve the advantages of low production cost, improved yield and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

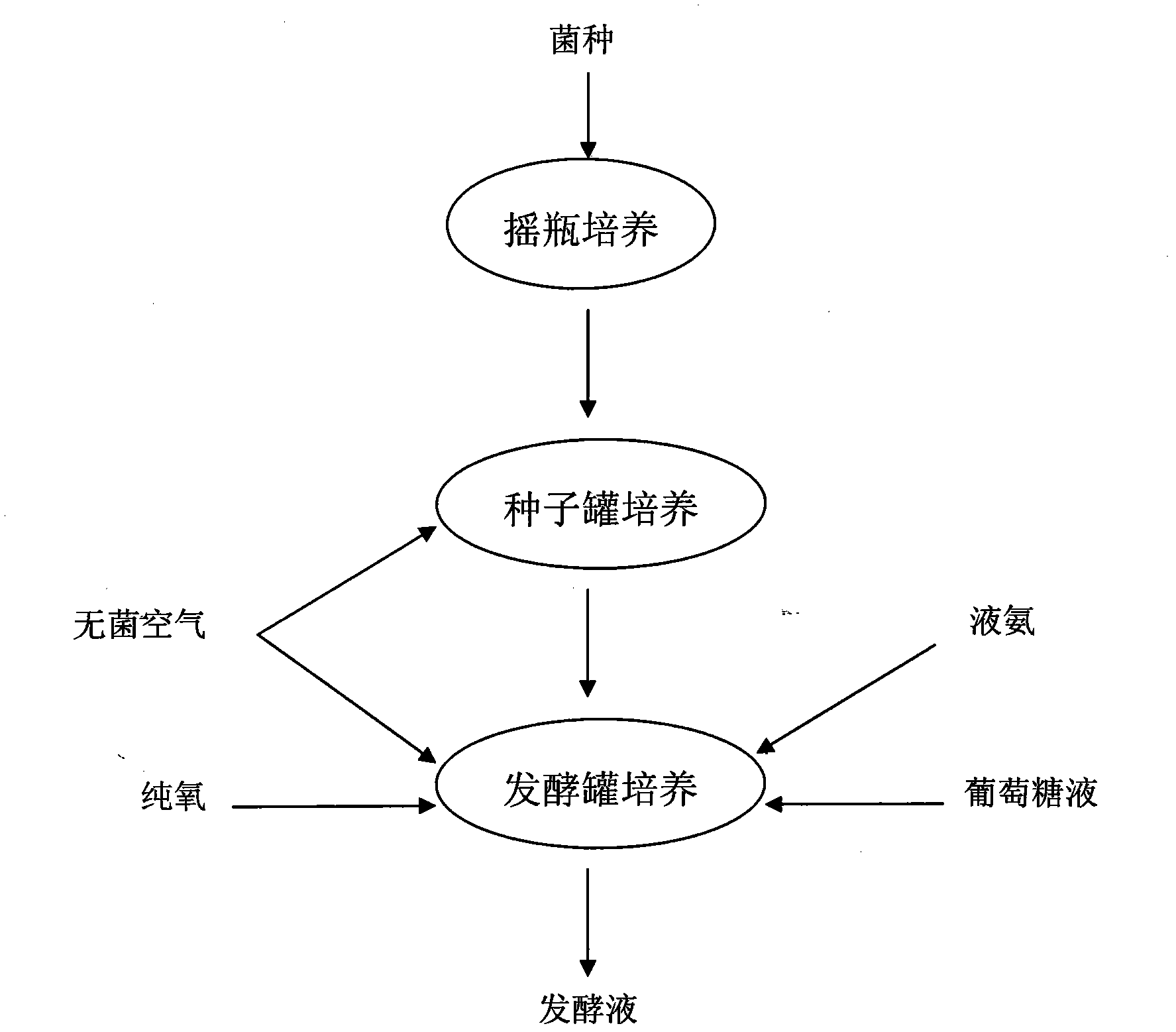

Image

Examples

Embodiment 1

[0012] Embodiment 1: a kind of method that improves fermentative production L-threonine productive rate, it comprises the following steps:

[0013] The strain used is Escherichia coli genetically engineered bacteria, and the medium is a commonly used medium. The cultivation method is as follows: insert the strain into the seed culture medium, cultivate in a 10L seed tank for 10h to the logarithmic growth phase under the conditions of controlled temperature of 37°C and dissolved oxygen of 20%, and transfer it into a 100L fermenter according to 10% inoculation amount Carry out fermentation culture. The temperature of the fermentation process is controlled at 37°C, the relative dissolved oxygen level of the process is controlled at 20%-30% by adjusting the pure oxygen feeding ratio, the pH of the fermentation broth is controlled by feeding liquid ammonia to 7.0-7.2, and an appropriate amount of foam is added to defoam, And by feeding liquid glucose dissolved oxygen with a mass c...

Embodiment 2

[0015] Embodiment 2: a method for improving the yield of L-threonine produced by fermentation, which includes the following steps:

[0016] The strain used is Escherichia coli genetically engineered bacteria, and the medium is a commonly used medium. The cultivation method is as follows: insert the strains into the seed medium, control the temperature at 37°C and dissolve oxygen at 20% in 15m 3 The seed tanks were cultured for 12 hours to the logarithmic growth phase, and the inoculation amount of 10% was inserted into a 150m3 fermenter for fermentation. The temperature of the fermentation process is controlled at 37°C, and the relative dissolved oxygen level of the process is controlled at 25%-35% by adjusting the ratio of pure oxygen feeding. And by feeding liquid glucose dissolved oxygen with a mass concentration of 600g / L, the mass concentration of residual sugar is controlled at 0.1%-0.5%, and the fermentation culture is completed for 36 hours.

[0017] When putting the...

Embodiment 3

[0018] Embodiment 3: A method for improving the yield of L-threonine produced by fermentation, which includes the following steps: the strain used is Escherichia coli genetically engineered bacteria, and the culture medium is a commonly used culture medium. The formulation method is as follows: insert the strains into the seed medium, cultivate them in a 15m3 seed tank for 12 hours to the logarithmic growth phase under the conditions of a controlled temperature of 37°C and 20% dissolved oxygen, and insert them into a 150m3 fermenter according to 10% of the inoculum Carry out fermentation culture. The temperature of the fermentation process is controlled at 37°C, the relative dissolved oxygen level of the process is controlled at 30%-40% by adjusting the pure oxygen feeding ratio, the pH of the fermentation broth is controlled by feeding liquid ammonia to 7.0-7.2, and an appropriate amount of foam is added to defoam, And by feeding liquid glucose dissolved oxygen with a mass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com