Film having low refractive index and method for producing the same, anti-reflection film and method for producing the same, coating liquid set for film having low refractive index, substrate having microparticle-laminated thin film, and method for pr

一种低折射率膜、制造方法的技术,应用在抗反射涂层、光学元件、涂层等方向,能够解决品质劣化、不耐热、热膨胀率小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0489] 1. Formation of microparticle laminated film

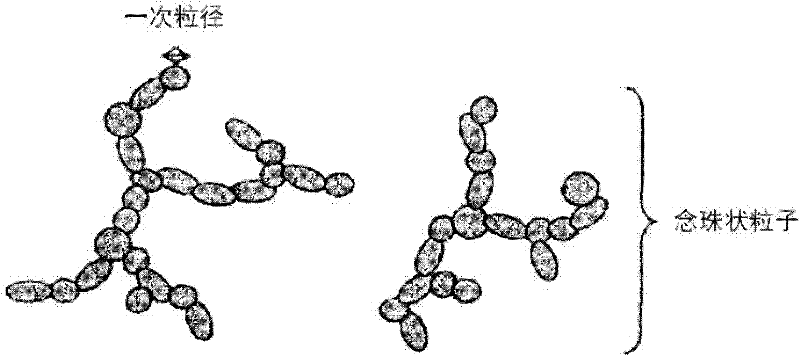

[0490] An aqueous dispersion of silica (manufactured by Nissan Chemical Industries, Ltd., trade name: SNOWTEX (ST) OUP, silica sol) in which bead-shaped silica fine particles having an average primary particle diameter of 8 nm measured by the BET method was dispersed in Without adjusting the pH, the concentration was adjusted to 1% by mass, and the resulting solution was used as a fine particle dispersion; An aqueous solution with a pH of 10 was used as an aqueous electrolyte polymer solution.

[0491] The following steps are carried out in sequence: Step (a), which is a silicon wafer (manufactured by SUMCO Corporation, 6PW-A1, 6 inches Φ, 625 μm thick) as a solid substrate, a glass substrate (manufactured by Matsunami Glass Co., Ltd., trade name: S1111 , 25mm × 75mm × 0.7mm thick, the refractive index at a wavelength of 550nm is 1.54), and a polystyrene plate (manufactured by Hikari, transparent, 1mm thick) irradiated wit...

Embodiment 2

[0505] First, according to the procedure of Example 1, a microparticle-laminated film was fabricated.

[0506] Next, 50 g of diphenyldimethoxysilane (alkoxysilane (I), manufactured by Shin-Etsu Chemical Co., Ltd., KBM202SS) was put into a 300 ml three-necked round-bottomed flask, 81 g of MeOH was added, and the solution was stirred at 25° C. to make the solution uniform. After adding 2.7 mass% H 3 PO 4 12.1 g of the aqueous solution was stirred at 25° C. for 4 hours to obtain a 35% solution (stock solution) with a silane concentration; The steps produce a low-refractive-index film.

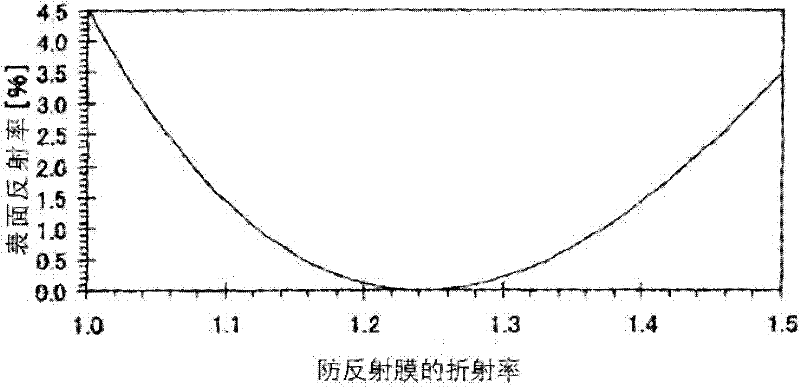

[0507] The low refractive index film evaluated in the same manner as in Example 1 had a refractive index of 1.3 and a thickness of 110 nm, and the haze of the low refractive index film evaluated in the same manner as in Example 1 was 0.3%. When the transmission spectrum of the glass substrate on which the low-refractive-index film was formed was measured similarly to Example 1, the maximum tran...

Embodiment 3

[0510] First, according to the procedure of Example 1, a microparticle-laminated film was produced.

[0511] Next, 50 g of hexyltriethoxysilane (alkoxysilane (I), manufactured by Shin-Etsu Chemical Co., Ltd., KBE3063) was put into a 300 ml three-necked round-bottomed flask, and 42 g of MeOH was added thereto. After stirring at 25° C. to make the solution uniform, add 0.05% by mass H 3 PO 4 7.4 g of the aqueous solution was stirred at 25° C. for 72 hours to obtain a solution (stock solution) with a silane concentration of 50%; The steps of making a low refractive index film.

[0512] The low refractive index film evaluated in the same manner as in Example 1 had a refractive index of 1.3 and a thickness of 110 nm, and the haze of the low refractive index film evaluated in the same manner as in Example 1 was 0.3%. When the transmission spectrum of the glass substrate on which the low-refractive-index film was formed was measured similarly to Example 1, the maximum transmittanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com