Method for preventing shell expansion of thick and large surface of precision-casting stainless steel casting

A technology of precision casting and stainless steel, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of affecting the quality of castings, increasing manufacturing costs, increasing labor load, etc. The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

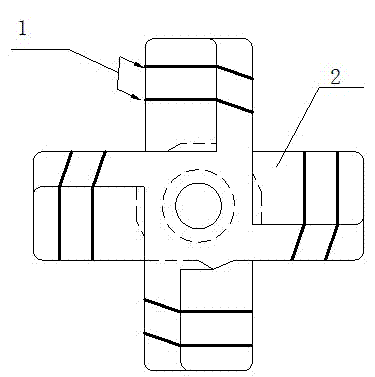

[0030] Embodiment 1: as figure 1 , 2 As shown, the rotor impeller 5802 is made by using the method of preventing the thick and large surface of the stainless steel casting from precision casting.

[0031] Proceed as follows:

[0032] (1) Shell making: Dip the wax mold of rotor impeller 5802 with zircon powder slurry, sprinkle zircon sand, and dry for 6 hours to form a surface shell;

[0033] The zircon powder slurry is composed of silica sol, wetting agent, and defoamer (the silica sol adopts JN30 silica sol produced by Qingdao Fusaike Casting Material Co., Ltd., and the lubricant adopts J.F.C. produced by Hangzhou Investment Precision Casting Research Institute. Lubricant and defoamer are composed of A-type defoamer produced by Shangyu Shuangyang Silicon Products Co., Ltd.) and 300-mesh zircon powder, with a weight ratio of 100:0.45:0.22:380; the sprinkled zircon sand is 100 mesh zircon sand;

[0034] Use the mullite powder slurry to dip the surface layer shell of the rot...

Embodiment 2

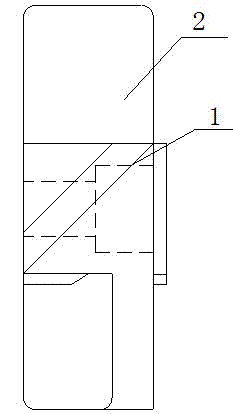

[0044] Embodiment 2: The L base 6205 is made by using the method of preventing the thick surface of the precision casting stainless steel casting from bulging.

[0045] Proceed as follows:

[0046] (1) Shell making: use zircon powder slurry to dip the wax mold of L base 6205 into the surface layer slurry, sprinkle zircon sand, and dry for 4-6 hours to form a surface layer shell;

[0047] The zircon powder slurry is composed of silica sol, wetting agent, and defoamer (the silica sol adopts JN30 silica sol produced by Qingdao Fusaike Casting Material Co., Ltd., and the lubricant adopts J.F.C. produced by Hangzhou Investment Precision Casting Research Institute. Lubricant and defoamer are composed of A-type defoamer produced by Shangyu Shuangyang Silicon Products Co., Ltd.) and 300-mesh zircon powder, and the weight ratio is 100: (0.45-0.47): (0.22-0.24): (360~400); the zircon sand sprinkled is 100 mesh zircon sand;

[0048] Use mullite powder slurry to dip the surface shell of...

Embodiment 3

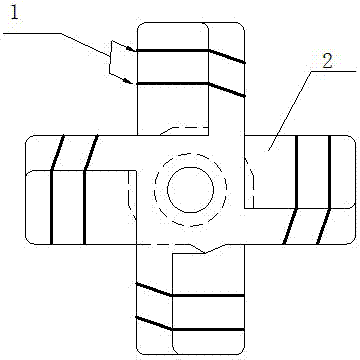

[0058] Embodiment 3: The guide rail 421 is made by using the method of preventing the thick surface of the precision casting stainless steel casting from bulging.

[0059] Proceed as follows:

[0060] (1) Shell making: Dip the wax pattern of the guide rail 421 with zircon powder slurry, sprinkle zircon sand, and dry for 5 hours to form a surface shell;

[0061] The zircon powder slurry is composed of silica sol, wetting agent, and defoamer (the silica sol can adopt JN30 silica sol produced by Qingdao Fusaike Casting Material Co., Ltd., and the lubricant adopts the product produced by Hangzhou Investment Precision Casting Research Institute. J.F.C lubricant and defoamer are composed of A-type defoamer produced by Shangyu Shuangyang Silicon Products Co., Ltd.) and 300-mesh zircon powder, with a weight ratio of 100:0.46:0.23:400; sprinkled zircon sand 100 mesh zircon sand;

[0062] Use mullite powder slurry to dip the surface shell of the guide rail 421 with two-layer slurry an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com