Processing and recycling method of waste water discharged from stainless steel pickling process

A technology for pickling wastewater and stainless steel, applied in the field of environmental engineering, can solve the problems of serious secondary pollution, difficult industrial promotion, high processing cost, and achieve the effect of small secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

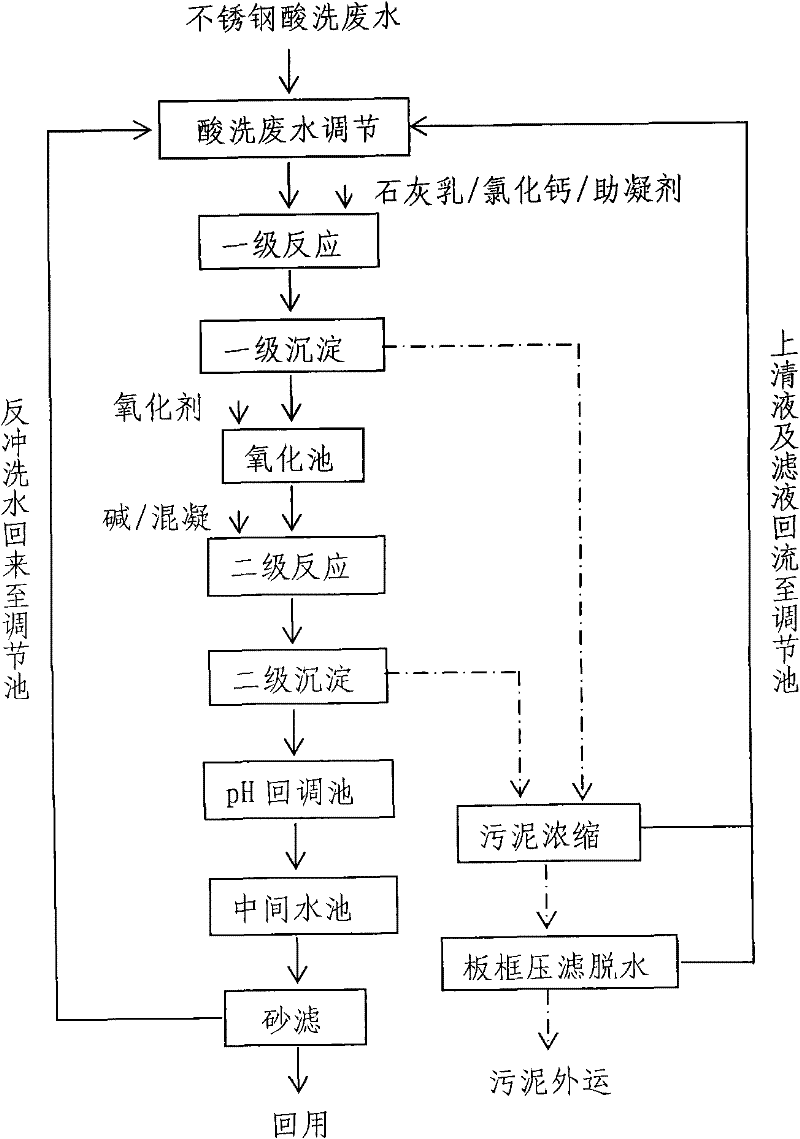

Image

Examples

Embodiment 1

[0021] 1) stainless steel pickling waste water, the water volume is 1000m 3 / d, the water quality is as follows: pH is 1.2, COD Cr 145mg / L, total chromium 420mg / L, total iron 750mg / L, Ni 2+ is 300mg / L, F- is 650mg / L, SS is 160mg / L, the wastewater is pumped into the regulating tank for water quality and water homogenization treatment, and the hydraulic retention time is 2h;

[0022] 2) Pump the effluent from the adjustment tank into the primary reaction tank, adjust the pH to 6.5 by adding lime milk, and add calcium chloride to make most of the fluoride ions in the wastewater react to form CaF 2 , and then add polyacrylamide with a weight percentage of 0.2g / L for flocculation, and the hydraulic retention time of the reaction tank is 0.5h;

[0023] 3) Pump the effluent from the primary reaction tank into the primary sedimentation tank, the hydraulic retention time is 1h, and pump the settled sludge into the sludge thickening tank;

[0024] 4) Pump the effluent from the primar...

Embodiment 2

[0032] 1) stainless steel pickling waste water, the water volume is 800m 3 / d, the water quality is as follows: pH is 1.5, COD Cr 126mg / L, total chromium 362mg / L, total iron 580mg / L, Ni 2+ is 244mg / L, F- is 765mg / L, SS is 186mg / L, the wastewater is pumped into the regulating tank for water quality and water homogenization treatment, and the hydraulic retention time is 2h;

[0033] 2) Pump the effluent from the adjustment tank into the primary reaction tank, adjust the pH to 6.5 by adding lime milk, and add calcium chloride to make most of the fluoride ions in the wastewater react to form CaF 2 , and then add polyacrylamide with a weight percentage of 0.2g / L for flocculation, and the hydraulic retention time of the reaction tank is 0.7h;

[0034] 3) Pump the effluent from the primary reaction tank into the primary sedimentation tank, the hydraulic retention time is 1.5h, and pump the settled sludge into the sludge thickening tank;

[0035] 4) Pump the effluent from the prima...

Embodiment 3

[0043] 1) stainless steel pickling waste water, the water volume is 640m 3 / d, the water quality is as follows: pH is 1.8, COD Cr 164mg / L, total chromium 372mg / L, total iron 850mg / L, Ni 2+is 350mg / L, F- is 850mg / L, SS is 196mg / L, the wastewater is pumped into the regulating tank for water quality and water homogenization treatment, and the hydraulic retention time is 2h;

[0044] 2) Pump the effluent from the adjustment tank into the primary reaction tank, adjust the pH to 6.5 by adding lime milk, and add calcium chloride to make most of the fluoride ions in the wastewater react to form CaF 2 , and then add polyacrylamide with a weight percentage of 0.2g / L for flocculation, and the hydraulic retention time of the reaction tank is 0.8h;

[0045] 3) Pump the effluent from the primary reaction tank into the primary sedimentation tank, the hydraulic retention time is 1h, and pump the settled sludge into the sludge thickening tank;

[0046] 4) Pump the effluent from the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com