Preparation method of combined phosphorus type flame-retardant acrylic ester pressure-sensitive adhesive

A technology of acrylate and pressure-sensitive adhesives, applied in the direction of adhesive types, adhesives, ester copolymer adhesives, etc., to achieve the effect of solving the technical bottleneck of balance, improving flame retardancy and stability, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 (Phosphorus-containing monomer PAM-300 accounts for 10%)

[0025] Step a: in N 2 Under protection, the design solid content is 40%, and the glass transition temperature is -61℃. Add 28.0gBA, 7.0g2-EHA, 12.7gVAc, 2.1gHEA, 1.1gAA, and 5.0g phosphorous monomer PAM-300 to 15g sequentially In a mixed solvent of xylene and 100 g of ethyl acetate, stir to make the mixture uniform and increase the temperature.

[0026] Step b: Add 0.4g of initiator BPO to 20g of ethyl acetate solvent and stir to dissolve and mix uniformly. When the temperature is raised to the reflux temperature of 78°C, the initiator is added dropwise. The dropwise addition is completed in about 0.5h, and the constant temperature reaction is 1.0h. Cool down to 75°C and react for 1.5h.

[0027] Step c: Add the remaining monomers: 28.0g BA, 7.0g 2-EHA, 11.0g VAc, 2.1g HEA, 1.0gAA, and 5.0gPAM-300 to the reaction solution in sequence, and raise the temperature for 10min to about 78℃, React for 0.5h after the...

Embodiment 2

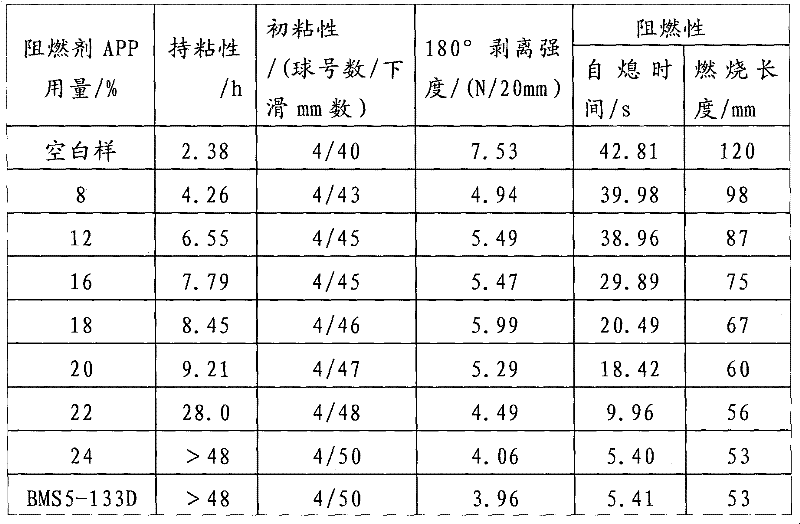

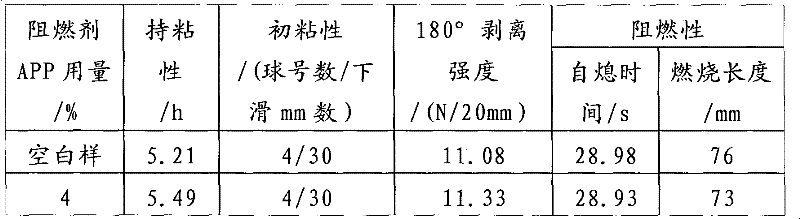

[0034] Example 2 (Phosphorus-containing monomer PAM-300 accounts for 10%, and ammonium polyphosphate APP accounts for different proportions)

[0035] Step a: in N 2 Under protection, the design solid content is 40%, and the glass transition temperature is -61℃. Add 28.0gBA, 7.0g2-EHA, 12.7gVAc, 2.1gHEA, 1.1gAA, and 5.0g phosphorous monomer PAM-300 to 15g sequentially In a mixed solvent of xylene and 100 g of ethyl acetate, stir to make the mixture uniform and increase the temperature.

[0036] Step b: Add 0.4g of initiator BPO to 20g of ethyl acetate solvent and stir to dissolve and mix uniformly. When the temperature is raised to the reflux temperature of 78°C, the initiator is added dropwise. The dropwise addition is completed in about 0.5h, and the constant temperature reaction is 1.0h. Cool down to 75°C and react for 1.5h.

[0037] Step c: Add the remaining monomers: 28.0g BA, 7.0g 2-EHA, 11.0g VAc, 2.1gHEA, 1.0g AA, and 5.0gPAM-300 to the reaction solution in sequence, and rais...

Embodiment 3

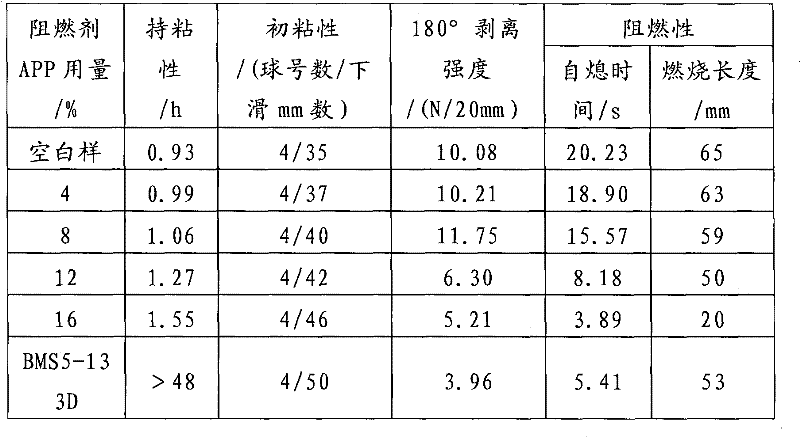

[0045] Example 3 (Phosphorus-containing monomer PAM-300 accounts for 20%)

[0046] Step a: in N 2 Under protection, the design solid content is 40%, the glass transition temperature is -60℃, and 23.3gBA, 7.0g2-EHA, 12.7gVAc, 2.1gHEA, 1.1gAA, and 10.0g phosphorous monomer PAM-300 are added to 15g in turn In a mixed solvent of xylene and 100 g of ethyl acetate, stir to make the mixture uniform and increase the temperature.

[0047] Step b: Add 0.4g of initiator BPO to 20g of ethyl acetate solvent and stir to dissolve and mix uniformly. When the temperature is raised to the reflux temperature of 78°C, the initiator is added dropwise. The dropwise addition is completed in about 0.5h, and the constant temperature reaction is 1.0h. Cool down to 75°C and react for 1.5h.

[0048] Step c: Add the remaining monomers: 23.0g BA, 7.0g 2-EHA, 11.0g VAc, 2.1g HEA, 1.0g AA, and 10.0gPAM-300 to the reaction solution in sequence, and increase the temperature by 10min to 78℃ About 0.5h after the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| 180°peel strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com