High-humidity and high-temperature resisting single component epoxy adhesive and its preparation method

An epoxy adhesive, high-humidity technology, applied in adhesives, novolak epoxy resin adhesives, epoxy resin adhesives, etc., can solve the problems of loose wiring structure, low water absorption, restrictions, etc., and reach the scope of application Wide range, extended application range, and high bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

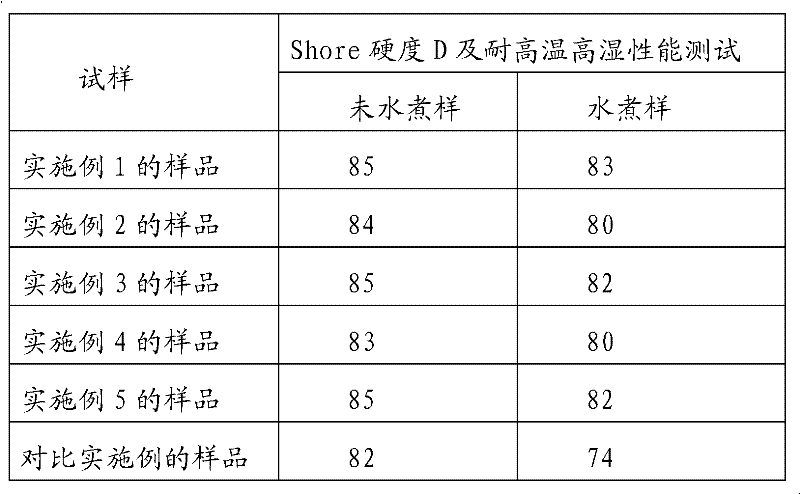

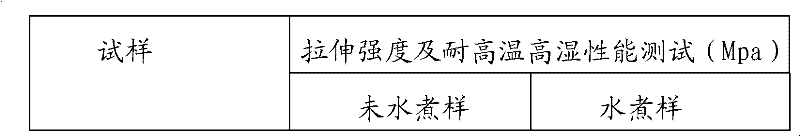

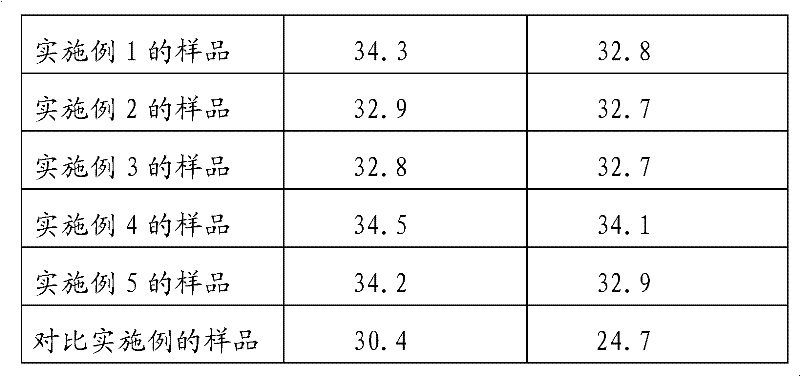

Examples

Embodiment 1

[0017] Accurately weigh each raw material according to the following weight percentages, bisphenol F epoxy resin: 30%, novolac epoxy resin 10%, ethylene glycol diglycidyl ether: 2%, silicon micropowder: 43%, silane active coupling Adding agent 0.5%, trimellitic anhydride 0.5%, liquid nitrile rubber 3%, latent curing agent imidazole: 8%, modified amine mixture M-10: 3%, add the above components into the double planetary power mixer in turn Inside, vacuumize to a vacuum degree of -0.08~-0.05MPa, stir at 500 rpm for 2 hours, stir evenly, let it air naturally to room temperature, and obtain a high-temperature and high-humidity one-component epoxy adhesive, which can be sealed and packaged.

Embodiment 2

[0019] Accurately weigh each raw material according to the following weight percentages, bisphenol A epoxy resin: 30%, novolac epoxy resin 10%, butanediol diglycidyl ether: 5%, kaolin: 33%, silane active coupling agent 1.5%, trimellitic anhydride 0.5%, epoxy-terminated nitrile rubber 10%, latent curing agent imidazole: 5%, modified imidazole Kingcure-390: 5%, add the above components in turn to double planetary dynamic mixing In the mixer, evacuate to a vacuum degree of -0.08~-0.05MPa, stir at 500 rpm for 2 hours, stir evenly, let it air naturally to room temperature, and obtain a high-temperature and high-humidity one-component epoxy adhesive, which can be sealed and packaged .

Embodiment 3

[0021] Accurately weigh each raw material according to the following weight percentages, bisphenol A type epoxy resin: 25%, bisphenol F type epoxy resin: 25%, multifunctional epoxy epoxy resin 10%, 1,2-cyclohexane Alcohol diglycidyl ether: 1%, diatomaceous earth: 21%, silane active coupling agent 1%, 3,3',4,4'-benzophenone tetraacid dianhydride 1%, epoxy-terminated butyronitrile Rubber 5%, latent curing agent imidazole: 8%, modified imidazole PN-40: 3%, add the above components into the double planetary power mixer in turn, and vacuum until the vacuum degree is -0.08~-0.05MPa, Stir at 500 rpm for 2 hours, stir evenly, and let it air naturally to room temperature to obtain a high-temperature and high-humidity one-component epoxy adhesive, which can be sealed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com