Preparation method of diesel oil low temperature flow properties improver

A low-temperature flow and improver technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., to achieve the effect of reducing the cloud point of diesel oil, good sensitivity, and excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

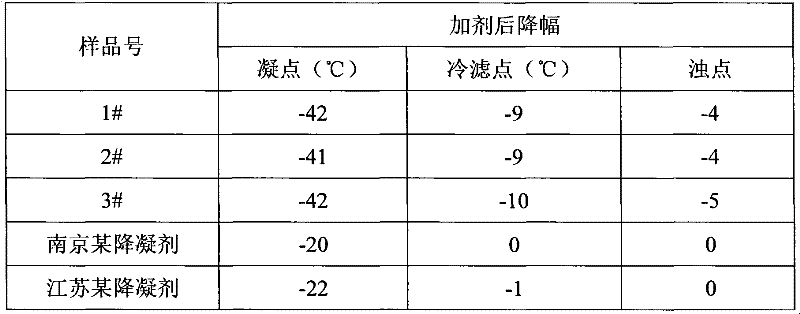

Examples

Embodiment 1

[0014] (1) Add 200ml of xylene to a 500ml esterification kettle, then add 81g of ethylene-vinyl acetate-vinyl alcohol copolymer, 4g of dodecylbenzenesulfonic acid, and 100g of lauric acid, and heat to reflux at 135°C to react After 10 hours, a mixture with a degree of esterification of 60% was obtained, which was distilled under reduced pressure at a vacuum of 3 kilopascals, and 215 g of C 9 , After stirring evenly, under cooling, add about 8g of tetradecylamine to obtain component A.

[0015] (2) Add 80 g of acrylic acid and 180 g of dodecanol to 1 g of concentrated sulfuric acid, add 5 g of hydroquinone, heat up to 120° C., and react for 5 hours. Add 84g of hexene-1 and 100g of maleic anhydride, heat up polymerization for 4.5 hours, add 213g of tetradecylamine, react at 180°C for 1 hour to form component B.

[0016] (3) Add solvent C to component A 9 , slowly add component B, heat and stir for 1 hour, slowly add component dioctyl phosphate, heat at 40-60°C and stir for 1 h...

Embodiment 2

[0018] (1) Add 180ml of xylene into a 500ml esterification kettle, then add 85.5g of ethylene-vinyl acetate-vinyl alcohol copolymer, 3g of p-toluenesulfonic acid, 50g of lauric acid and 72g of stearic acid, and heat to 140°C Reflux and react for 10 hours to obtain a mixture with a degree of esterification of about 55%, distill under reduced pressure at a vacuum of 2.5 kPa, add 205 g of C 9 , After stirring evenly, under cooling, add about 8g of decylamine to obtain component A.

[0019] (2) 80 g of acrylic acid and 214 g of myristyl alcohol were added with 1 g of concentrated sulfuric acid, 5 g of hydroquinone, heated to 130° C., and reacted for 5 hours. Add 80g of hexene-1 and 90g of maleic anhydride, heat up polymerization for 4 hours, add 160g of decylamine, react at 175°C for 1 hour to form component B.

[0020] (3) Add C to component A 9 , slowly add component B, heat and stir for 1 hour, slowly add dioctyl phosphate, heat and stir for 1 hour, that is, composite diesel ...

Embodiment 3

[0022] (1) Add 180ml of xylene into a 500ml esterification kettle, then add 80g of ethylene-vinyl acetate-vinyl alcohol copolymer, 3g of p-toluenesulfonic acid, and 143g of stearic acid, heat to reflux at 140°C, and react for 12 hours , to obtain a mixture with a degree of esterification of about 70%, distill under reduced pressure at a vacuum of 3 kPa, add 195gC 9 After stirring evenly, under cooling, add about 6g of hexadecylamine to obtain component A.

[0023] (2) 80 g of acrylic acid and 180 g of lauryl alcohol were added to 1 g of concentrated sulfuric acid, 5 g of hydroquinone was added, the temperature was raised to 120° C., and the reaction was carried out for 5 hours. Add 80g of hexene-1 and 100g of maleic anhydride, heat up polymerization for 5 hours, add 214g of tetradecylamine, react at 185°C for 1 hour to form component B.

[0024] (3) Add C to component A 9 , slowly add component B, heat and stir for 1 hour, slowly add dioctyl phthalate, heat and stir for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com