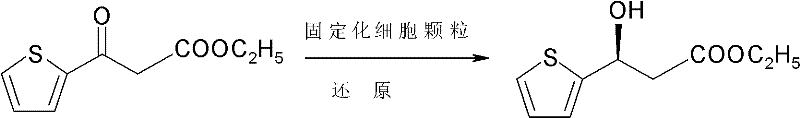

Method for inversing microbe to prepare ethyl (S)-3-hydroxy-3-(2-thienyl)-propanoate

A technology of microbial transformation and ethyl propionate, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low production efficiency, emulsification, and affecting extraction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of slant medium: wort juice 10g / L, yeast powder 3g / L, peptone 5g / L, glucose 10g / L, agar 20g / L, natural pH value, solvent is water, sterilized at 121°C for 20min to make slant spare.

[0046] Preparation of seed medium: glucose 30g / L, yeast powder 3g / L, ammonium sulfate 5g / L, anhydrous MgSO 4 0.25g / L, K 2 HPO 4 ·3H 2 O 1g / L, KH 2 PO 4 1g / L, natural pH value, solvent is water, sterilized at 121°C for 20min, ready for use.

[0047] The composition of the fermentation medium was the same as that of the seed medium.

[0048] Slant culture: Saccharomyces cerevisiae CGMCC No.2266 strain was inoculated in the slant medium, cultured at 30° C. for 4 to 6 days, and the slant of the bacteria was obtained.

[0049]Seed culture: use an inoculation needle to take an inoculation ring from the slant of the bacterium and inoculate it into a 250mL Erlenmeyer flask containing 100mL of the seed medium, and cultivate it at 30°C and 180r / min for 24 hours to obtain the seed ...

Embodiment 2

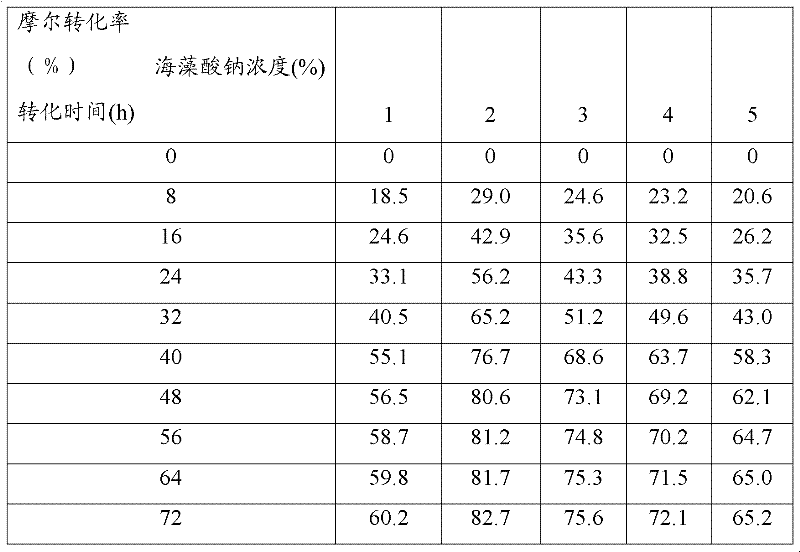

[0056] Saccharomyces cerevisiae CGMCC No.2266 was cultivated according to the method in Example 1 to obtain a bacterial cell fermentation broth. Four portions of 100 mL of fermentation broth with a bacterial cell concentration of 4.3 g / mL were mixed with an equal volume of 2% sodium alginate aqueous solution, and the mixed solutions were respectively filled into syringes with needle sizes of 2 mm, 3 mm, 4 mm, and 5 mm. Add dropwise 500mL 3.5% (w / v) CaCl 2 Form immobilized particles in the aqueous solution, the diameters of the formed immobilized particles are 2mm, 3mm, 4mm and 5mm respectively, solidify at 37°C for 30min, and the obtained immobilized particles are washed with sterile physiological saline to remove excess calcium ions and untreated particles. For the captured cells, the obtained immobilized cell particles were cultured in 500mL fermentation medium at 30°C for 24 hours, filtered, and 4 immobilized cell particles after proliferation were obtained. The diameters o...

Embodiment 3

[0062] Saccharomyces cerevisiae CGMCC No.2266 was cultivated according to the method in Example 1 to obtain a bacterial cell fermentation broth. Four parts of 100mL of fermented liquid with a cell concentration of 4.3g / mL were mixed with an equal volume of 2% sodium alginate aqueous solution, the mixed solution was respectively packed into a syringe with a needle size of 2mm, and 500mL of 3.5% (w / v) CaCl 2 Form immobilized particles in an aqueous solution, the diameter of the formed immobilized particles is 2 mm, solidify at 37 ° C for 30 min, and the obtained immobilized particles are washed with sterile physiological saline to remove excess calcium ions and uncaptured cells, and the obtained 4 The immobilized cell granules were respectively cultured in 500mL fermentation medium at 30°C for 0h, 24h, 48h and 72h to obtain immobilized cell granules after proliferation.

[0063] Add the above 4 portions of immobilized cell particles after proliferating culture to 300mL dibutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com