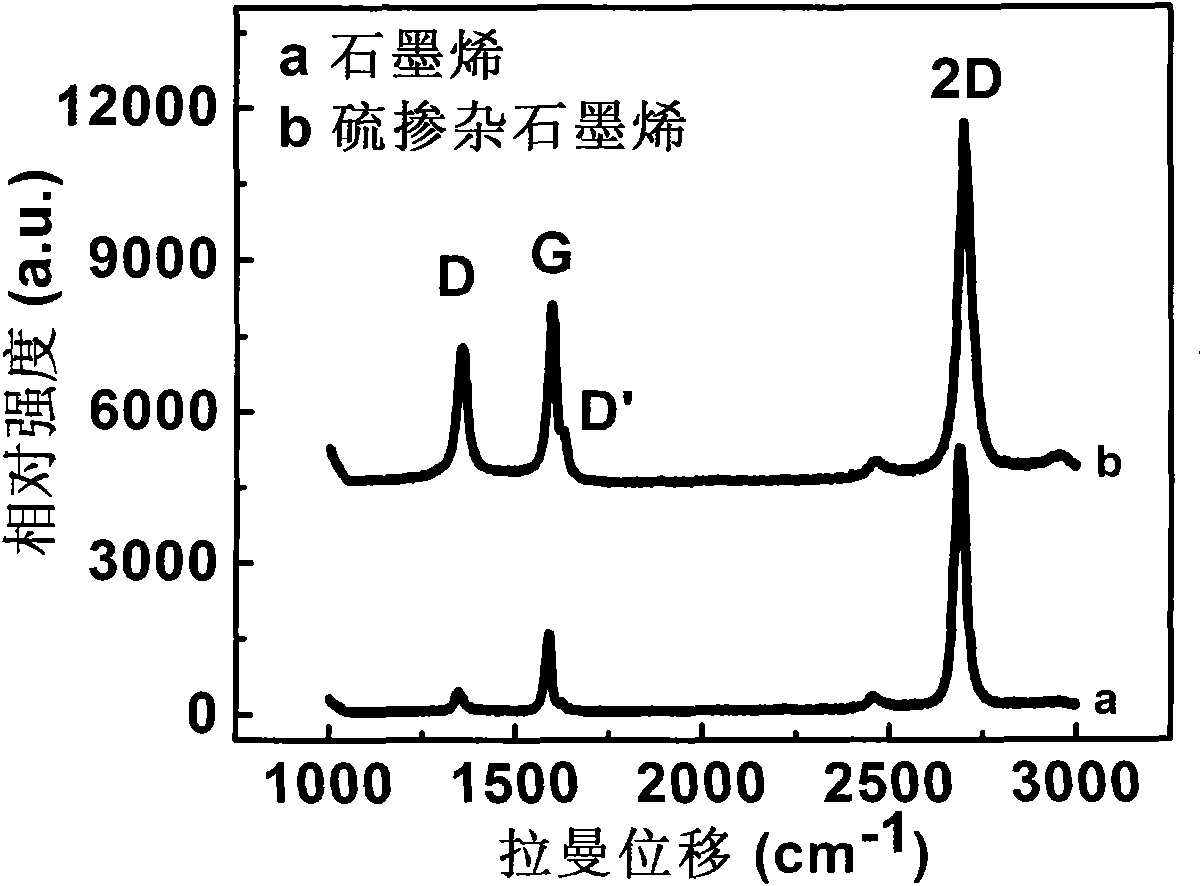

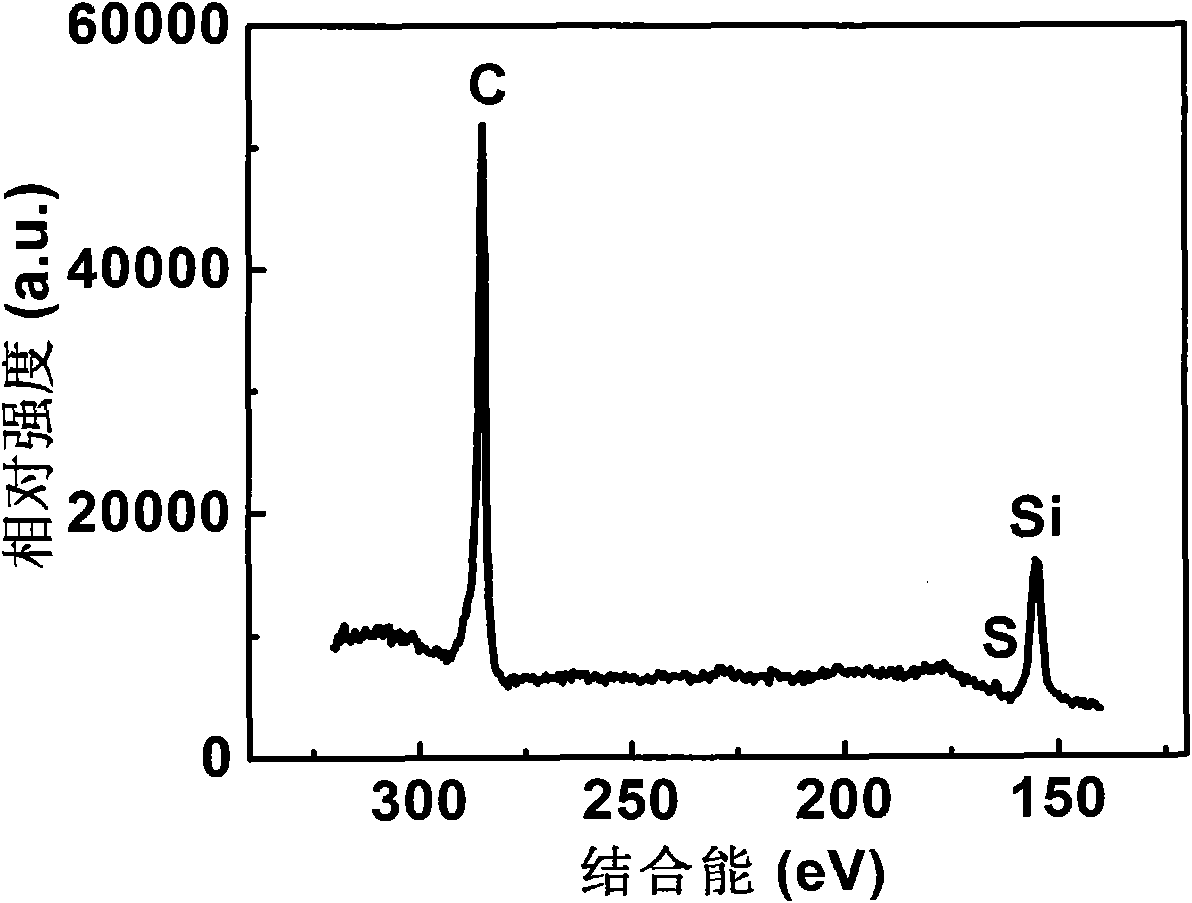

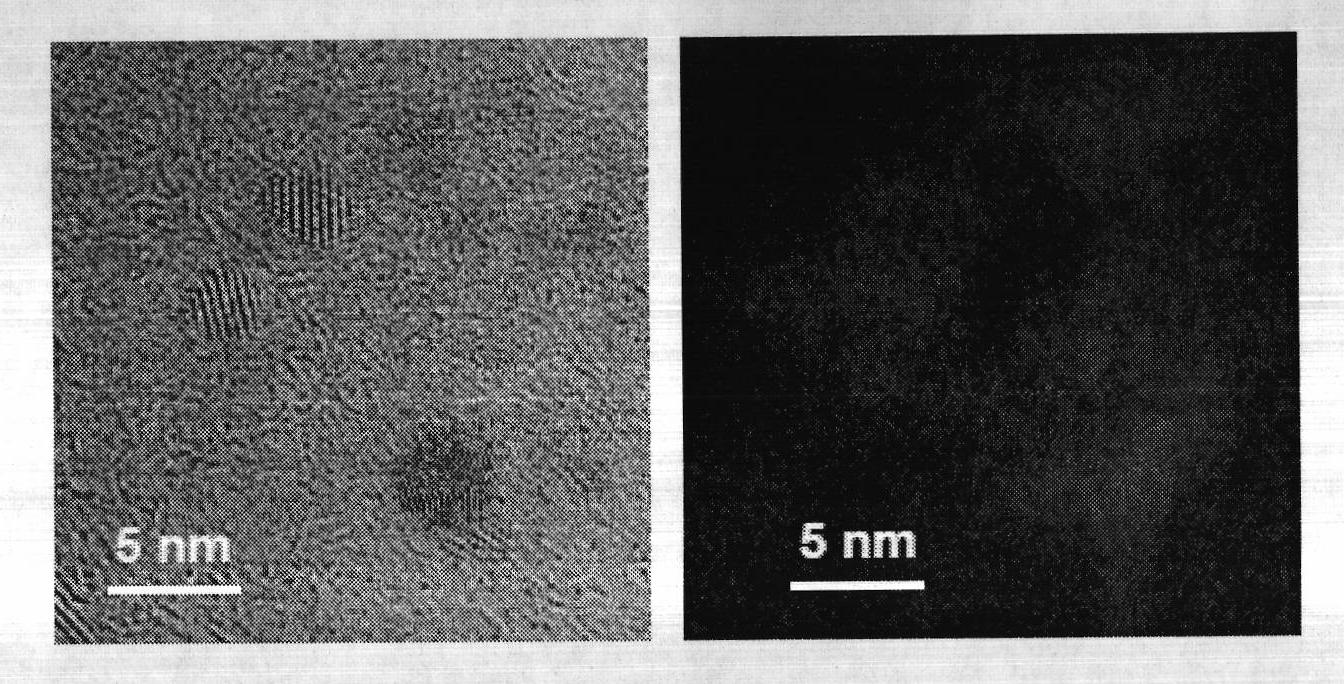

Method for preparing sulfur-doped graphene films

A technology of sulfur-doped graphene and thin films, applied in chemical instruments and methods, gaseous chemical plating, crystal growth and other directions, to achieve the effects of simple and feasible preparation process, stable product quality, and convenience for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the first step, hexane and sulfur powder are mixed, and the mixed liquid is treated under ultrasonic waves for about 20 minutes to form a uniform and transparent solution. Wherein the consumption of hexane is 50ml, and the sulfur powder is 1mg.

[0022] In the second step, the metal copper substrate is placed in the center of the quartz tube, and the entire chemical vapor deposition (CVD) system is evacuated to 10 -3 torr, into the reducing protective atmosphere H 2 Mix gas with Ar (volume ratio 1:5) until the pressure in the system reaches 10-11 torr (gas flow rate is about 400 sccm); heat the metal substrate at 500°C for about 30 minutes.

[0023] In the third step, when the temperature of the center of the electric furnace reaches 950°C, stop introducing the reducing protective atmosphere, and make the vacuum degree in the furnace reach 10°C. -3 torr, introduce the mixed liquid precursor of hexane and sulfur powder into the reaction system, control its feed rate...

Embodiment 2

[0028] In the first step, hexane and sulfur powder are mixed, and the mixed liquid is treated under ultrasonic waves for about 20 minutes to form a uniform and transparent solution. Wherein the consumption of hexane is 50ml, and the sulfur powder is 1mg.

[0029] In the second step, the metal copper substrate is placed in the center of the quartz tube, and the entire chemical vapor deposition system is evacuated to 10 -3 torr, into the reducing protective atmosphere H 2 Mix gas with Ar (1:5) until the pressure in the system reaches 10-11 torr (the gas flow rate is about 400 sccm); raise the temperature to 500° C. and heat-treat the metal substrate for about 30 minutes.

[0030] In the third step, when the temperature of the center of the electric furnace reaches 950°C, stop introducing the reducing protective atmosphere, and make the vacuum degree in the furnace reach 10°C. -3 torr, introduce the mixed liquid precursor of hexane and sulfur powder into the reaction system, co...

Embodiment 3

[0035] In the first step, hexane and sulfur powder are mixed, and the mixed liquid is treated under ultrasonic waves for about 20 minutes to form a uniform and transparent solution. Wherein the hexane consumption is 50ml, and the sulfur powder is 1.5mg.

[0036] In the second step, the metal copper substrate is placed in the center of the quartz tube, and the entire chemical vapor deposition system is evacuated to 10 -3 torr, into the reducing protective atmosphere H 2 Mix gas with Ar (1:5) until the pressure in the system reaches 10-11 torr (the gas flow rate is about 400 sccm); raise the temperature to 500° C. and heat-treat the metal substrate for about 30 minutes.

[0037] In the third step, when the temperature of the center of the electric furnace reaches 950°C, stop introducing the reducing protective atmosphere, and make the vacuum degree in the furnace reach 10°C. -3 torr, introduce the mixed liquid precursor of hexane and sulfur powder into the reaction system, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com