Lightweight rigid ceramic heat-insulation tile and manufacture method thereof

A technology of heat insulation tiles and ceramics, applied in the field of porous ceramic materials, can solve the problems of high manufacturing cost, stop of research work, and poor performance of alumina fibers and aluminum borosilicate, so as to improve heat insulation performance and mechanical properties, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

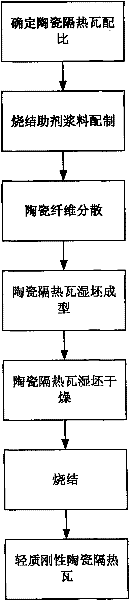

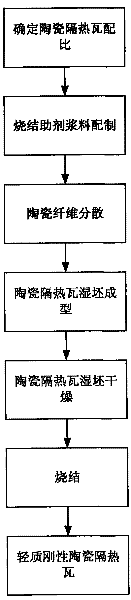

Method used

Image

Examples

example 1

[0035] (1) Weigh 84g of boron nitride and disperse it in 1000mL of ethanol, after the dispersion is uniform, set aside.

[0036] (2) Weigh 1912g of quartz fiber, 350g of mullite fiber, 207g of starch, and mix the solution in (1) with 100L of deionized water, and use a mechanical stirrer to uniformly disperse the fibers in deionized water to obtain a slurry.

[0037] (3) Transfer the above-mentioned slurry to a forming mold, and vacuum filter; transfer the filter cake to a pressure forming machine, apply a pressure of 7-9 MPa to form, and obtain a ceramic heat-insulating tile wet blank.

[0038] (4) Put the wet body of the ceramic heat-insulating tile into an oven at 80-120° C. and dry it for 24-48 hours to obtain a dry body of the ceramic heat-insulating tile.

[0039] (5) Put the dry ceramic tile into a high-temperature sintering furnace and treat it at 1200-1500°C for 4-10 hours to obtain a ceramic tile with a density of 0.33g / cm 3 ; The tensile strength in the plane direct...

example 2

[0041] (1) Weigh 84g of boron nitride and 100g of silicon carbide and disperse them in 2000mL of absolute ethanol, and disperse evenly before use.

[0042] (2) Weigh 1912g of quartz fiber, 350g of mullite fiber, 207g of starch, and mix the solution in (1) with 100L of deionized water, and use a mechanical stirrer to uniformly disperse the fibers in deionized water to obtain a slurry.

[0043] (3) Transfer the above slurry to a forming mold, and vacuum filter; transfer the filter cake to a pressure forming machine, apply a pressure of 8-10 MPa to form, and obtain a ceramic heat-insulating tile wet body.

[0044] (4) Put the wet body of the ceramic heat-insulating tile into an oven at 80-120° C. and dry it for 24-48 hours to obtain a dry body of the ceramic heat-insulating tile.

[0045] (5) Put the dry body of the ceramic heat-insulating tile into a high-temperature sintering furnace, and treat it at 1200-1500° C. for 4-10 hours to obtain the ceramic heat-insulating tile. The ...

example 3

[0047] (1) Weigh 38.2g of boron nitride and disperse it in 1000mL of ethanol, evenly disperse it, and set it aside.

[0048] (2) Weigh 870 g of quartz fiber, 240 g of mullite fiber, 94 g of starch, and mix the solution in (1) with 100 L of deionized water, and use a mechanical stirrer to uniformly disperse the fibers in deionized water to obtain a slurry.

[0049] (3) Transfer the above-mentioned slurry to a forming mold, and vacuum filter; transfer the filter cake to a pressure forming machine, apply a pressure of 4-6 MPa to form, and obtain a ceramic heat-insulating tile wet body.

[0050] (4) Put the wet body of the ceramic heat-insulating tile into an oven at 120-150° C. and dry it for 12-36 hours to obtain a dry body of the ceramic heat-insulating tile.

[0051] (5) Put the dry body of the ceramic heat-insulating tile into a high-temperature sintering furnace, and treat it at 1300-1500° C. for 4-8 hours to obtain a ceramic heat-insulating tile. The density is 0.15g / cm 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com