Production method of jiji mushroom strain and jiji mushroom fruiting body

A technology of jiji mushrooms and strains, applied in fungi, botanical equipment and methods, mushroom cultivation, etc., can solve problems such as lowering the culture temperature, lowering the production efficiency of fruiting bodies, and unclear causes or mechanisms of inoculum sclerosis, etc. Achieve the effect of simple screening method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] 62 g of sawdust (fir wood) in dry weight, 60 g of rice bran (moisture content 10%) in wet weight, 30 g of corncob powder (10% in water content) in wet weight, and 20 g of soybean hulls in wet weight (moisture content 10%), wheat bran (moisture content 10%) that wet weight is 20g is fully mixed, with 2.5g / bottle or 15g / bottle (relative to the total dry weight of solid culture medium, with dry weight ratio 1.1% by weight, 6.4% by weight, respectively) were added to the mixture obtained by adding magnesium aluminum silicate (18% dry loss, produced by Fuji Chemical Industry Co., Ltd., trade name: Noysilin), and the moisture content After adjusting to 65%, it was press-packed in a polypropylene wide-mouth culture bottle with a capacity of 850 mL (ブロビビン S-850, manufactured by Shin-Etsu Agricultural Supplies Co., Ltd.). In the center of the surface of the pressed product, an inoculation hole with a diameter of about 1 cm is opened, and after the lid is closed, it is autoclaved...

Embodiment 2

[0149] The following discusses whether the temperature of cultivating mycelium when adding 15g of aluminum magnesium silicate has an effect on the selection of strains that are not prone to or do not occur inoculum sclerosis.

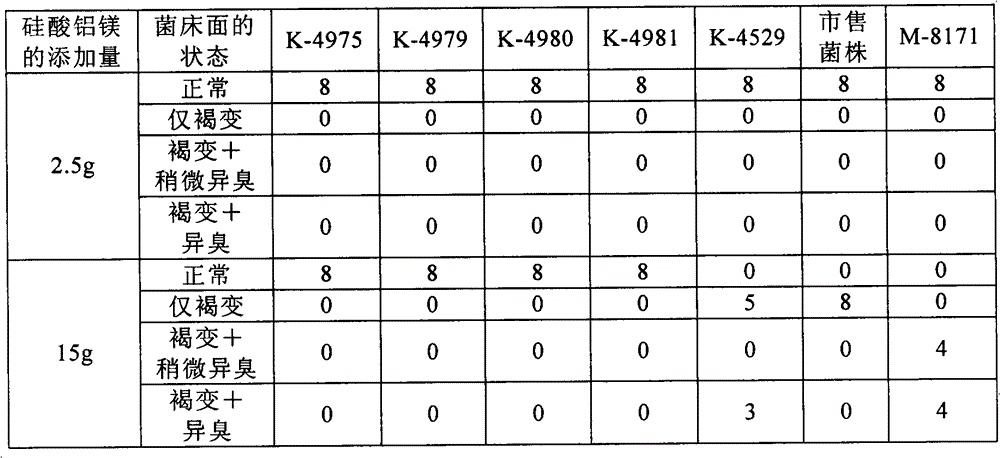

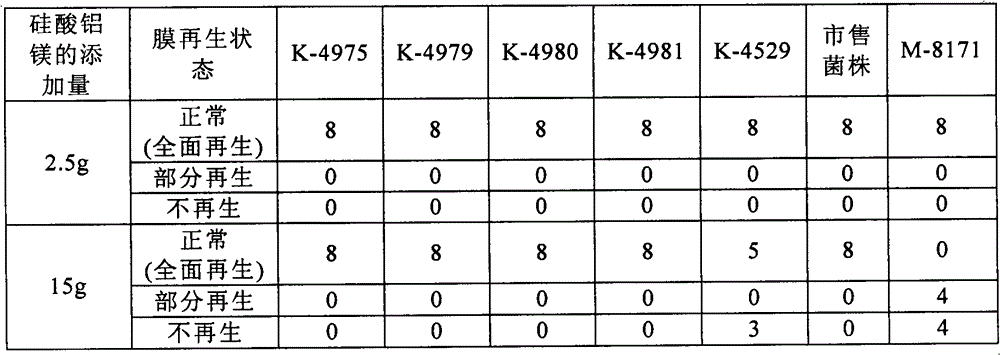

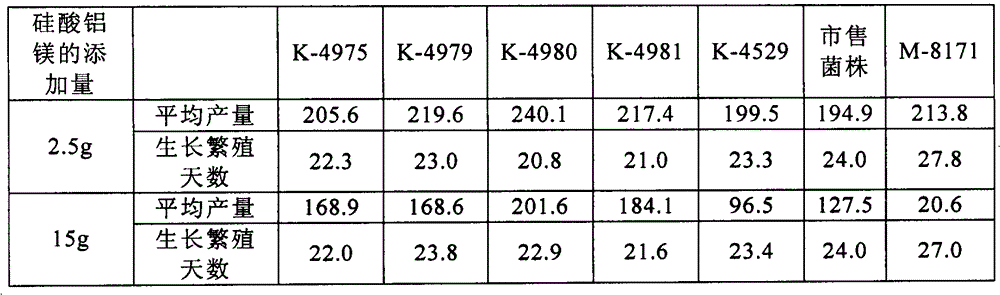

[0150] Using a solid cultivation medium to which 15 g of magnesium aluminum silicate was added, the temperature at the time of cultivating mycelium was set at 25°C and 27°C, and the same method as that described in Example 1 was adopted. , for Hypsizygusmarmoreus K-4975(FERMBP-11321), K-4979(FERMBP-11322), K-4980(FERMBP-11323), K-4981(FERMBP-11324), K-4529, for comparison The commercially available strains and Ulmus edulis M-8171 (FERMBP-1415) were studied. First, check the state of the fungus bed surface when scratching the fungus. The results are shown in Table 4.

[0151] [Table 4]

[0152]

[0153] As can be seen from Table 4, under the condition of adding 15 g of magnesium aluminum silicate and the culture temperature of the mycelia is 25° C....

Embodiment 3

[0164] Adopt the method identical with embodiment 2, to true Ji mushroom (Hypsizygusmarmoreus) K-4975 (FERMBP-11321), K-4979 (FERMBP-11322), K-4980 (FERMBP-11323), K-4981 (FERMBP-11324 ), K-4529, commercially available strains for comparison, and Ulmushimega M-8171 (FERMBP-1415), the difference is that 5g / bottle was added (relative to the total amount of solid culture medium Dry weight, being about 2.5% by weight in terms of dry weight ratio) aluminum oxide magnesium hydroxide (co-precipitation of aluminum hydroxide and magnesium hydroxide, drying loss 10%, produced by Kyowa Chemical Industry Co., Ltd., trade name: キヨ一ワ一ド300) to replace magnesium aluminum silicate. First, check the state of the fungus bed surface when scratching the fungus. The results are shown in Table 7.

[0165] [Table 7]

[0166]

[0167] As can be seen from Table 7, under the conditions of adding 5 g of alumina magnesium hydroxide and the culture temperature of mycelium being either 25° C. or 27° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com