Flat solar heat absorption coated plate production method and vertical coating apparatus

A flat-panel solar energy and coating device technology, applied in the field of solar thermal utilization, can solve problems such as inability to produce large areas, high deposition rate, and inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

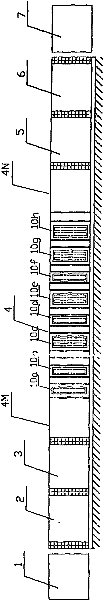

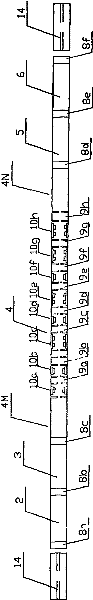

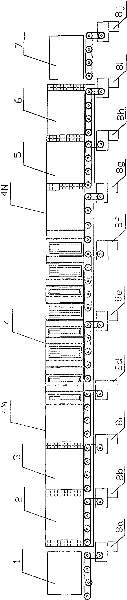

[0050] Figure 1 to Figure 12 Figure 1 of this example is given. This embodiment introduces the method and device for depositing at least one group of "interference film stack" film system type solar heat absorbing coating plate film, the selected film system is substrate / Al infrared light reflection layer / AlN dielectric layer / stainless steel metal layer / AlN dielectric layer / stainless steel metal layer / AlN anti-reflection layer, including two sets of AlN / stainless steel interference film stacks, with 2000×1000×0.2mm aluminum as the substrate. see figure 1 , figure 2 , the present embodiment device comprises upper film area 1, front vacuum lock chamber 2, front holding chamber 3, continuous coating chamber 4, rear holding chamber 5, rear vacuum lock chamber 6, lower film area 7, slide rack 14 (referring to Figure 6 , Figure 7 ), there are pegs 15 on the carrier 14, a piece of metal substrate 16 is hung on both sides of the carrier, the round rod-shaped bottom 17 of the ...

Embodiment 2

[0060] Figure 3 ~ Figure 11 , Figure 13 , Figure 15 , Figure 16 Figure 2 of Embodiment 2 of the present invention is given. The present embodiment 2 is basically the same as the embodiment 1, and the difference is that the present embodiment mainly deposits Figure 13 A kind of solar energy heat-absorbing film plate of the " heat-absorbing semiconductor material film system " type of nitrogen oxide shown, the film system that selects is substrate 16 / Al infrared light reflection layer 18 / CrNiOyNx semiconductor absorption layer (heat-absorbing semiconductor material film) 34 / SiN anti-reflection layer 35, with an aluminum material of 2000×1000×0.2mm as the substrate. The transmission system, the transmission mechanism, the transmission mode of the substrate, the sputtering target and the structure of the corresponding sputtering chamber of the coating device are all the same as those in Example 1. Figure 3 ~ Figure 11 The structure and method shown are the same, but acc...

Embodiment 3

[0067] Figure 3 ~ Figure 11 , Figure 14 , Figure 17 , Figure 18 Figure 3 of Embodiment 3 of the present invention is given. The present embodiment 3 is basically the same as the embodiment 1, and the difference is that the present embodiment mainly deposits Figure 14 Shown " metal dielectric composite material film " (or be referred to as " metal-doped dielectric material ") type a kind of solar heat absorbing coating plate, the film system that needs to use is substrate 16 / Al infrared light reflective layer 18 / AlNx metal-dielectric composite material layer 36 / AlNy metal-dielectric composite material layer 37 / AlN anti-reflection layer 38, wherein the filling factor of Al in AlNx is higher than the filling factor of Al in AlNy, also adopting the same size of 2000×1000×0.2mm aluminum as the substrate.

[0068] In this embodiment, the transmission system, the transmission mechanism, the transmission mode of the substrate, the structure of the magnetron sputtering targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com