Method for preparing light thermal diffusion junction for silicon solar cell

A silicon solar cell and photothermal technology, applied in the field of solar cells, can solve problems such as affecting production cost and production efficiency, complex process flow, difficult process control, etc., to reduce masking and high temperature processes, simplify preparation process flow, reduce Effects of heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

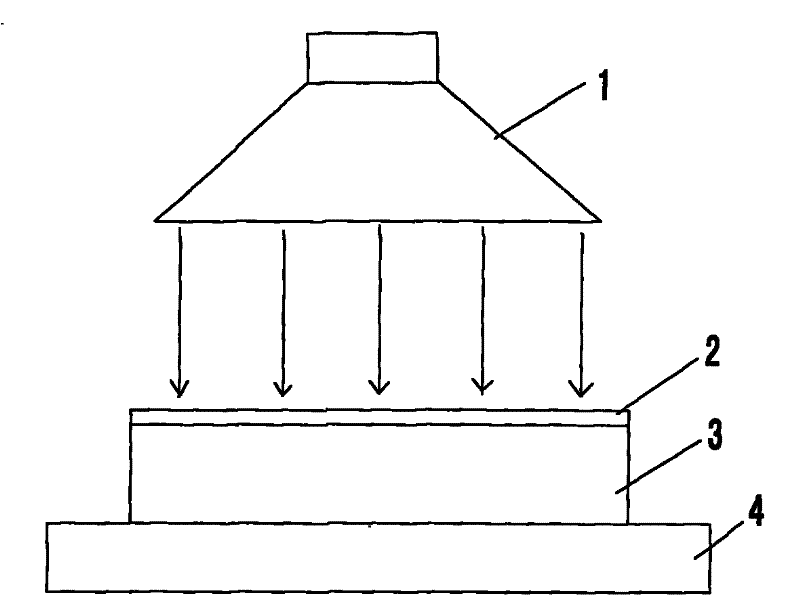

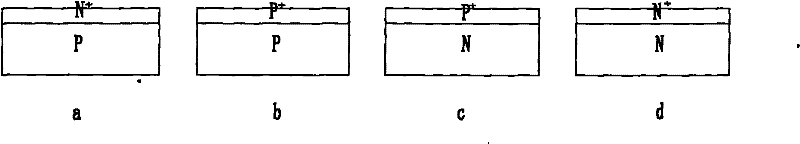

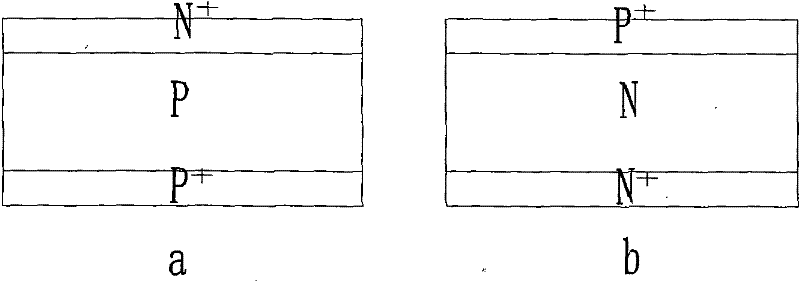

[0023] see figure 1 , the light-induced thermal diffusion junction method of silicon solar cells of the present invention is to place the P-type silicon wafer 3 (or N-type silicon wafer) on the back temperature control device 4 with temperature adjustment function. The backside temperature control device 4 plays an auxiliary role in raising the temperature of the entire silicon wafer by controlling the temperature of the backside (ie, the non-diffusion surface) of the silicon wafer 3 . According to the actual situation, the silicon wafer can be raised to a certain temperature in advance to increase the diffusion rate. Apply a layer of N-type slurry 2 with a certain thickness and concentration evenly on the surface of the P-type silicon wafer. Through the transmission device ( figure 1 (not shown in ) send the silicon wafer to the heating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com