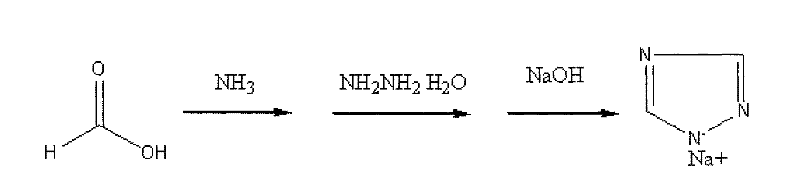

Preparation of granular 1,2,4-triazole sodium salt

A technology of triazole sodium salt and triazole sodium, which is applied in the field 1, can solve the problems of harsh operating environment, unfavorable process, and inaccurate measurement of workers, and achieves easy feeding and storage, good fluidity, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 164g of formic acid in a 500mL three-necked flask, add 350mL 25% ammonia water dropwise at 20-30℃, stir for 30min, heat up to 165-170℃, slowly add 80g hydrazine hydrate dropwise, while steaming ammonia water, keep warm Hours, cooling to obtain triazole. Add 45% NaOH solution dropwise to the triazole system. The temperature is at 30-40°C and the pH is 10-11. Stop the dropwise addition. Stir for 2-3 hours to precipitate crystals to obtain 1,2,4-triazole The crude sodium azole product is in powder form, and the particle size of more than 80% by weight of the powder is less than 60 microns.

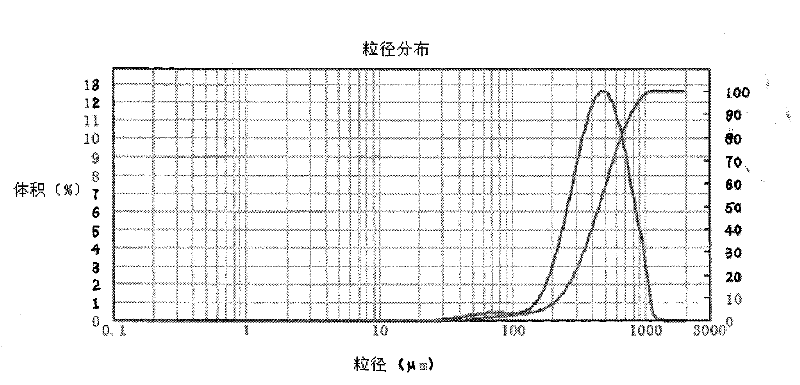

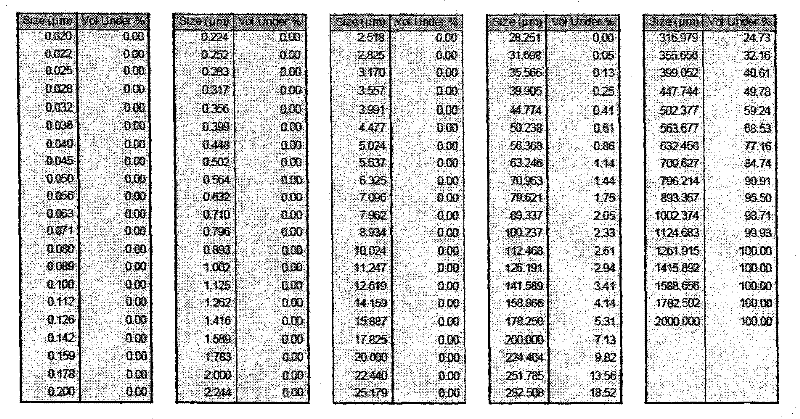

[0040] Add 250g of pure water to the obtained crude sodium triazole, stir, heat to clear, reflux for 30 minutes, adjust the stirring speed to 20-30 revolutions / min, and slowly reduce to 8-10 at a speed of 2-3°C / min ℃, filter. First, in a vacuum state at 50-60℃, after drying off most of the surface water, slowly heat up to 105℃, continue to bake until the moisture content is less tha...

Embodiment 2

[0046] Add 180g of formic acid to a 500mL three-necked flask, add 400mL of 25% ammonia water dropwise at 25-35°C, stir for 50min, heat to 160-165°C, slowly add 90g hydrazine hydrate dropwise, while steaming ammonia water, keep warm for about 3.5 hours , Cool to obtain triazole. Add 48% NaOH solution dropwise to the triazole system. The temperature is at 35-45°C and the pH is 11-12. Stop the dropwise addition. Stir for 3-4 hours to precipitate crystals to obtain 1,2,4-triazole The crude sodium azole product is in powder form, and the particle size of more than 70% by weight of the powder is less than 55 microns.

[0047] Add 250g of methanol to the obtained crude sodium triazole, stir, heat to clear, reflux for 60min, adjust the stirring speed to 20-30 rpm, and slowly reduce to 8-10 ℃ at a speed of 5-8 ℃ / min ,filter. First, in a vacuum at 30-40℃, after drying off most of the surface methanol, slowly increase the temperature to 70℃ for 2 hours, and finally rise to 110℃, and conti...

Embodiment 3

[0051] Add 150g of formic acid to a 500mL three-necked flask, add 320mL of 25% ammonia water dropwise at 30-35°C, stir for 50min, heat to 150-160°C, slowly add 75g hydrazine hydrate dropwise, while steaming ammonia water, keep warm for about two hours , Cool to obtain triazole. Add 40% NaOH solution dropwise to the triazole system. The temperature is at 20-30°C and the pH is 10.5-11.5. Stop the dropwise addition. Stir for 3-4 hours to precipitate crystals to obtain 1,2,4-triazole The crude sodium azole product is in powder form, and the particle size of more than 85% by weight of the powder is less than 70 microns.

[0052] Add 300 g of ethanol to the crude sodium triazole product, stir, heat to clear, reflux for 90 min, adjust the stirring speed to 40-50 revolutions / min, and slowly reduce to 0-5°C at a rate of 10-15°C / min ,filter. First, in a vacuum state of 30-40℃, after drying off most of the surface ethanol, slowly increase the temperature to 80℃ for 2 hours, and finally ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com