Multiphase composite system infrared radiation ceramic powder and preparation method thereof

A technology of ceramic powder and infrared radiation, which is applied in the field of infrared radiation materials, can solve problems such as unstable infrared radiation performance, achieve excellent infrared radiation performance, reduce thermal expansion coefficient, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

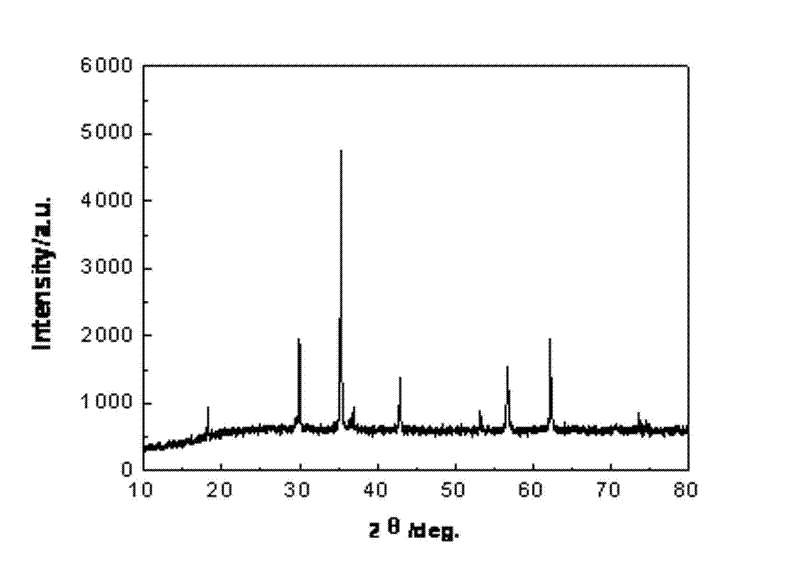

[0035] Embodiment 1: by mass ratio: 50% Fe 2 o 3 , 30%MnO 2 , 6%CuO, 6%Mo 2 o 3 , 5%V 2 o 5 , 3%WO 3 For batching, the above ingredients are ball milled, mixed, dried and pressed into a block body, solid-phase synthesized at 1115°C for 3 hours, then crushed and crushed, and passed through a 320 mesh sieve to prepare a spinel solid solution Ceramic powder.

[0036] According to mass ratio: 40% spinel solid solution ceramic powder, 21% Al 2 o 3 , 26%SiO2 2 , 10%MgO, 1.5%BaO, 1.5%CaO for batching, the above ingredients were ball milled, mixed, dried and pressed to form a block green body, solid-phase synthesis was carried out at 1290°C for 5 hours, and then crushed and pulverized. 320-mesh sieve to prepare spinel-silicate multiphase composite system ceramic powder.

[0037]The normal full-band emissivity of the spinel-silicate multiphase composite system ceramic powder is 0.90, the emissivity of the 8μm~25μm band is 0.93, the emissivity of the 8μm~14μm band is 0.92, an...

Embodiment 2

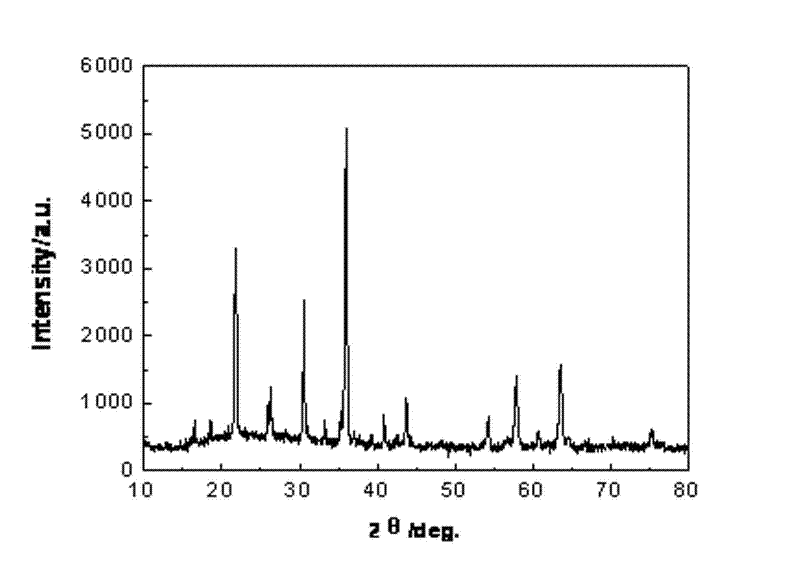

[0038] Embodiment 2: by mass ratio: 30%Fe 2 o 3 , 49%MnO 2 , 10%Co 2 o 3 , 3%Mo 2 o 3 , 3%V 2 o 5 、5%WO 3 The batching is carried out, and the above ingredients are ball milled, mixed, dried, shaped, and solid-phase synthesized at 1050°C for 6 hours, then crushed and pulverized, and passed through a 320-mesh sieve to prepare spinel-type solid solution ceramic powder.

[0039] According to mass ratio: 20% spinel solid solution ceramic powder, 60% Al 2 o 3 , 11%SiO2 2 , 6%TiO 2 , 3% CaO for batching, the above ingredients were ball milled, mixed, dried and shaped, solid-phase synthesized at 1300 ° C for 2 hours, then crushed and pulverized, and passed through a 200-mesh sieve to prepare spinel-silicate poly Phase composite system ceramic powder.

[0040] The normal full-band emissivity of the spinel-silicate multiphase composite ceramic powder is 0.89, the emissivity in the 8μm~25μm band is 0.94, the emissivity in the 8μm~14μm band is 0.91, and the radiation in the ...

Embodiment 3

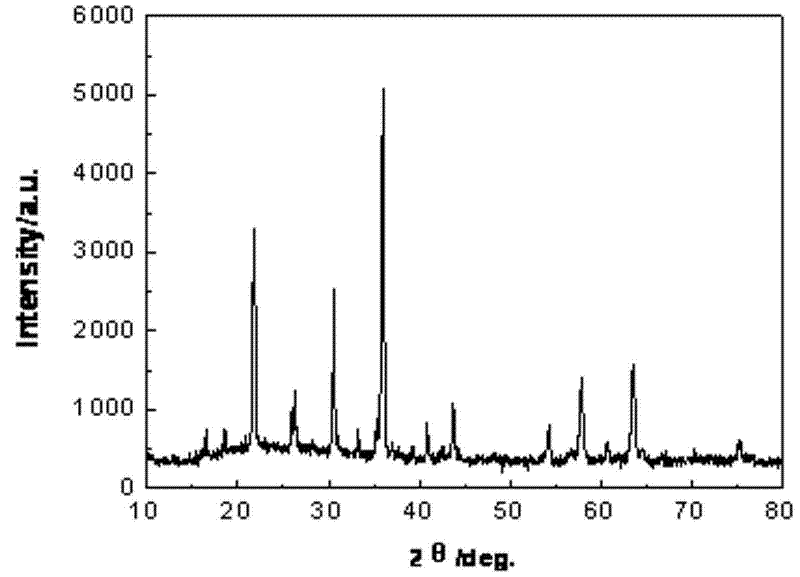

[0041] Embodiment 3: by mass ratio: 60%Fe 2 o 3 , 13%MnO 2 , 12%CuO, 5%Co 2 o 3 , 5%V 2 o 5 、5%WO 3 For batching, the above ingredients are ball milled, mixed, dried and formed, solid-phase synthesized at 1180° C. for 1 hour, then crushed and pulverized, and passed through a 320 mesh sieve to prepare spinel solid solution ceramic powder.

[0042] According to mass ratio: 20% spinel solid solution ceramic powder, 15.5% Al 2 o 3 , 56%SiO2 2 , 5% MgO, 3% BaO, 0.5% CaO for batching, the above ingredients were ball milled, mixed, dried and shaped, solid-phase synthesized at 1050 ° C for 8 hours, then crushed and pulverized, passed through a 500-mesh sieve, and prepared Spinel-silicate multiphase composite system ceramic powder.

[0043] The normal full-band emissivity of the spinel-silicate multiphase composite system ceramic powder is 0.89, the emissivity of the 8μm~25μm band is 0.92, the emissivity of the 8μm~14μm band is 0.91, and the radiation of the 14μm~25μm band T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com