Automatic acidless continuous furfural hydrolysis system

A furfural and furfural slag technology, applied in the field of furfural acid-free continuous automatic hydrolysis system, can solve the problems of high production cost, low comprehensive utilization rate, corrosion, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

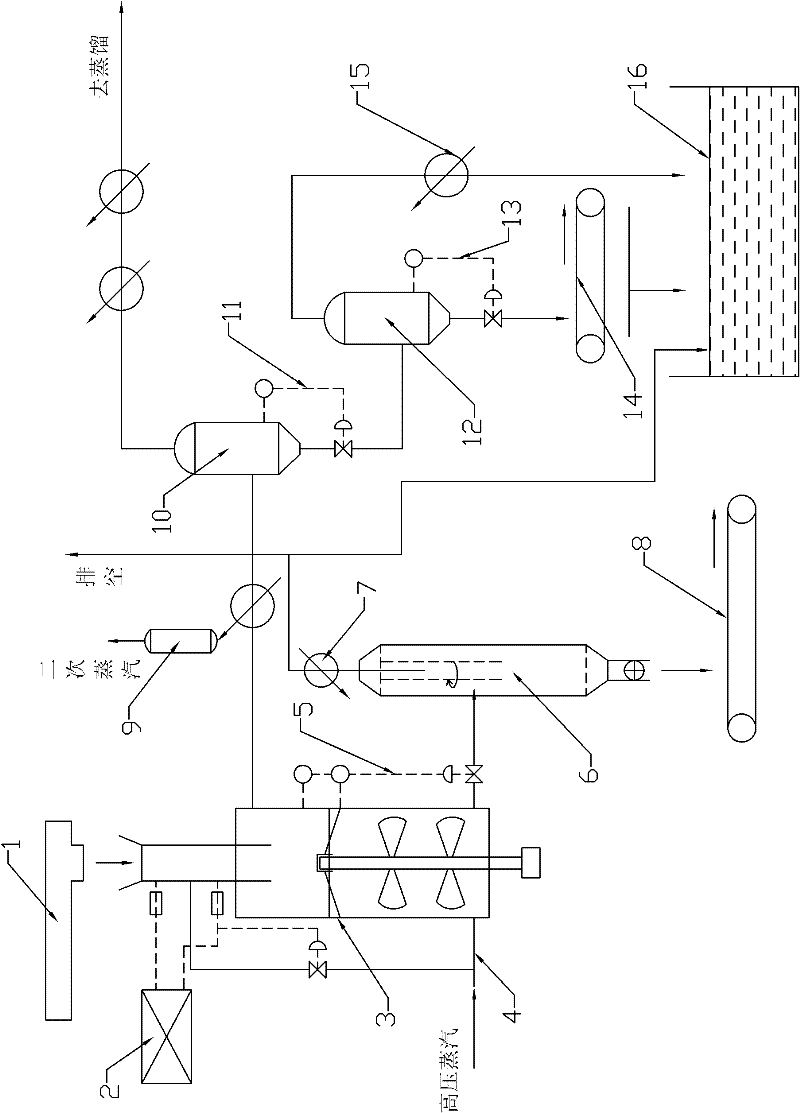

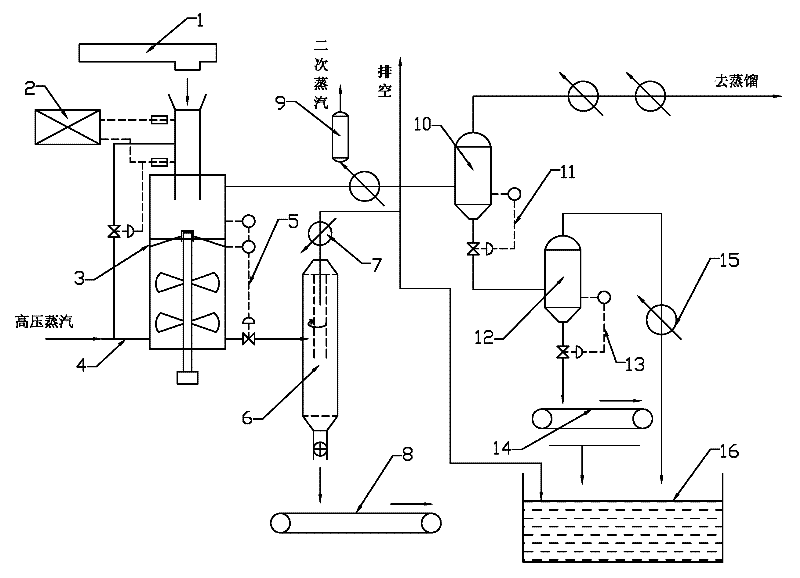

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] like figure 1 shown. The furfural acid-free continuous automatic hydrolysis system includes a feed unit, a hydrolysis unit and a residue treatment unit. The residue treatment unit includes a solid-liquid separation unit and a raw liquid storage tank 16. Secondary steam is provided between the hydrolysis unit and the solid-liquid separation unit. Generator 9; described feed unit comprises feeder 1 and automatic control feed system 2, and hydrolysis unit comprises continuous hydrolysis reactor 3, and solid-liquid separation unit comprises furfural slag separator 6, self-evaporator 10, cyclone-liquid separation device 12, conveyor belt 8 and rotary slagging device 14; the slag outlet of the continuous hydrolysis reactor 3 is connected with the furfural slag separator 6, and the aldehyde vapor outlet is connected with the secondary steam generator 9, the self-evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com