Clostridium butyricum and production method of clostridium butyricum feed additive

A feed additive, the technology of Clostridium butyricum, applied in the field of microbial fermentation, can solve the problems of high cost of liquid culture, high requirements for equipment and environment, and achieve the effect of small material loss, simple equipment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 7

[0077] Solid-state fermentation medium (%): cottonseed meal hydrolyzed by neutral protease for 1 hour 27; rice bran 9; glucose 1.5; brewer’s yeast powder 2.5; CaCO 3 0.02; water 60.

[0078] Inoculation and culture conditions: inoculum size 10% (v / w), natural pH, culture temperature 37±1°C, culture time 48 hours.

[0079] The number of live bacteria measured was 1.16×10 9 cfu / g.

example 8

[0081] Solid-state fermentation medium (%): cottonseed meal hydrolyzed for 3 hours by neutral protease 27; rice bran 9; glucose 1.5; beer yeast powder 2.5; CaCO 3 0.02; water 60.

[0082] Inoculation and culture conditions: inoculum size 10% (v / w), natural pH, culture temperature 37±1°C, culture time 48 hours.

[0083] The number of live bacteria measured was 2.25×10 9 cfu / g.

[0084] result

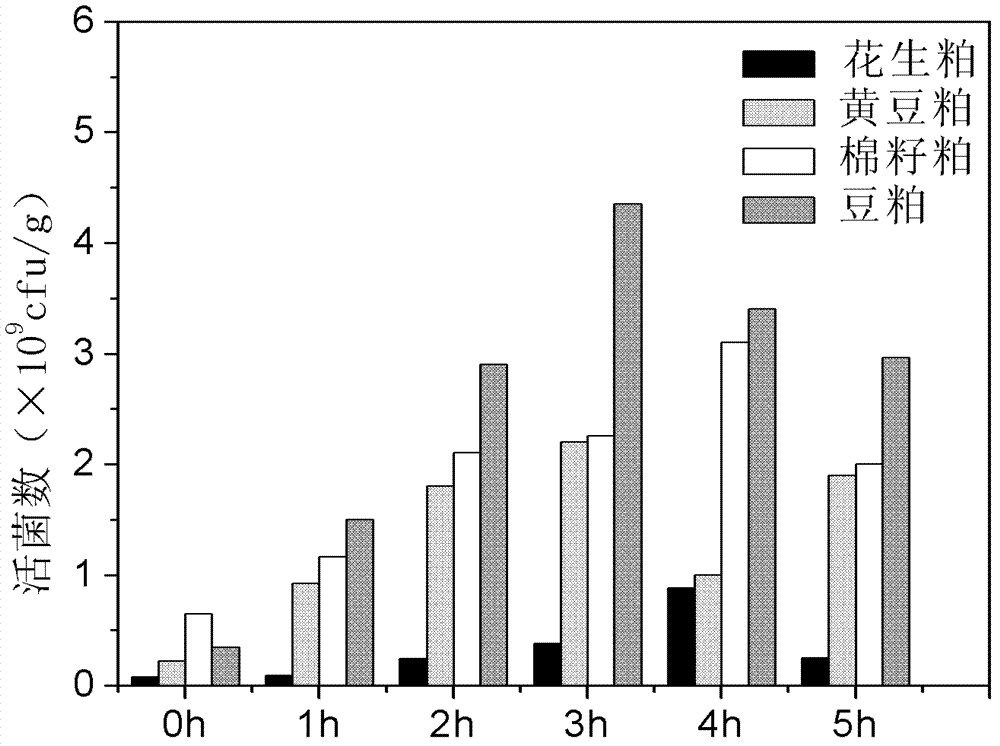

[0085] Clostridium butyricum TK2 uses cheap soybean meal, peanut meal, soybean meal, and cottonseed meal as nitrogen sources. After treatment with neutral protease, its utilization rate has been greatly improved, especially soybean meal after hydrolysis for 3 hours (attached figure 1 ), the effect is remarkable, the number of live bacteria is as high as 4.35×10 9 cfu / g, which greatly reduces the cost for the large-scale production of Clostridium butyricum. Therefore, soybean meal hydrolyzed with neutral protease for 3 hours was selected as the nitrogen source.

[0086] 3. Determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com