Method for preparing high purity alkoxysilanes from polysilicon byproduct silicon tetrachloride

A technology of high-purity alkoxysilane and silicon tetrachloride, applied in the direction of chlorine/hydrogen chloride, silicon organic compounds, etc., can solve the problems of blocked pipelines, silicon tetrachloride is volatile, etc., and achieves increased productivity and stable product quality , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

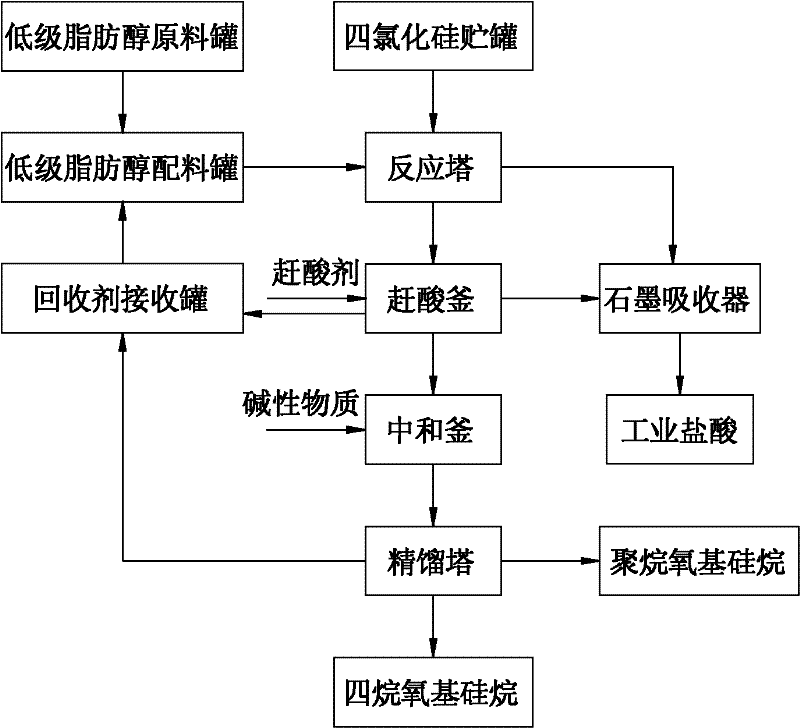

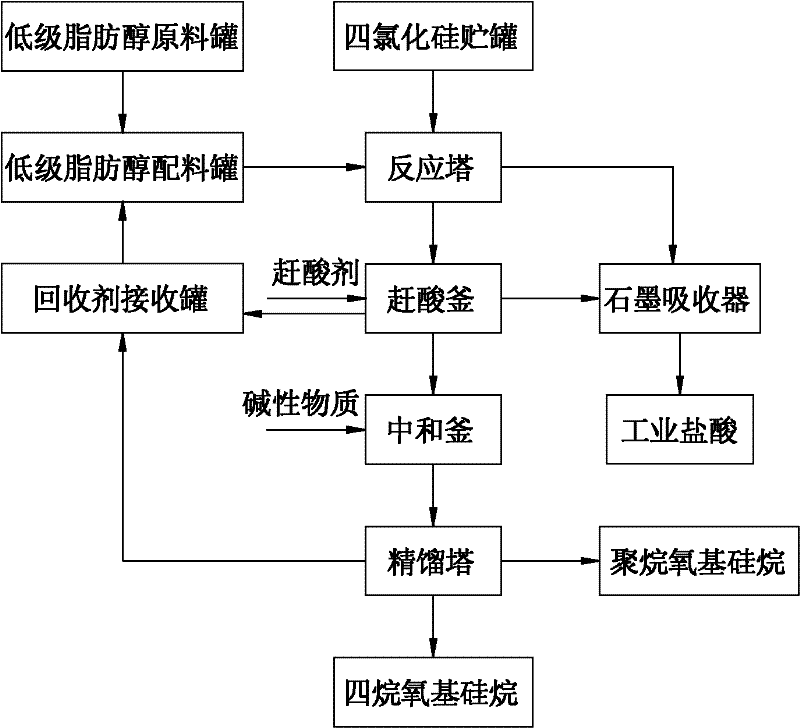

Image

Examples

Embodiment 1

[0053] Embodiment 1 Utilizes polysilicon by-product silicon tetrachloride to prepare high-purity tetraethoxysilane

[0054] A small amount of ethanol is pre-added in the packed reaction tower, and the molar ratio of silicon tetrachloride and ethanol is 1.0:4.1 and simultaneously passed into the reaction tower. Reaction material of ethoxysilane and hydrogen chloride. The hydrogen chloride gas generated by the reaction is absorbed by water in a graphite absorber to obtain industrial hydrochloric acid.

[0055] Press the reaction material into the acid catcher, slowly heat to the bottom temperature of 130°C, distill off the unreacted raw materials and part of hydrogen chloride; add the acid catcher ethanol for the first time, the dosage is 1.0 times the mole of silicon tetrachloride, Heating to the bottom temperature of 130°C, distilling off the acid dispersing agent and hydrogen chloride; adding the acid catching agent ethanol for the second time, the dosage is 1.0 times the mo...

Embodiment 2

[0066] A small amount of recovering agent was pre-added in the packed reaction tower, and silicon tetrachloride and the recovering agent recovered in Example 1 (calculated as pure ethanol) were simultaneously passed into the reaction tower at a molar ratio of 1.0:4.1. Other conditions are with embodiment 1.

[0067] The purity of the tetraethoxysilane product is 99.6%, and the yield is over 96%. Each batch of finished tetraethoxysilane is a colorless transparent liquid, specific gravity 0.934 (20°C), acidity (HCl) ≤ 10ppm, boiling point 169°C, kinematic viscosity 0.7mm 2 / s.

[0068] Each batch of finished polyethoxysilane is a colorless transparent liquid with a purity of 98%, an acidity (HCl) ≤ 10ppm, a specific gravity of 0.96-1.00 (20°C), and a kinematic viscosity of 1-1.6mm 2 / s, the content of silicon in polyethoxysilane is SiO 2 Calculated as 30 to 34%.

Embodiment 3

[0070] Ethanol and recovering agent (in terms of pure ethanol) are passed into the ethanol batching tank in a molar ratio of 1.0: 1.0, a small amount of ethanol mixed solution is added in advance in the packed reaction tower, and then the molar ratio of silicon tetrachloride and ethanol mixed solution is 1.0:4.1 is passed into the reaction tower at the same time. Other conditions are with embodiment 1.

[0071] The purity of the tetraethoxysilane product is 99.7%, and the yield is over 95%. Each batch of finished tetraethoxysilane is a colorless transparent liquid, specific gravity 0.934 (20°C), acidity (HCl) ≤ 10ppm, boiling point 169°C, kinematic viscosity 0.7mm 2 / s.

[0072] Each batch of finished polyethoxysilane is a colorless transparent liquid with a purity of 98%, an acidity (HCl) ≤ 10ppm, a specific gravity of 0.96-1.00 (20°C), and a kinematic viscosity of 1-1.6mm 2 / s, the content of silicon in polyethoxysilane is SiO 2 Calculated as 30 to 34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com