Method for self-lubricating treatment of laser micro-texture of bearing

A processing method and micro-modeling technology, which is applied to bearing components, shafts and bearings, laser welding equipment, etc., can solve problems that affect bearing fitting accuracy and support rigidity, increase process difficulty and cost, and affect lubrication effect, etc., to achieve savings Dosage, ensure stable supply and uniform coating, and ensure the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

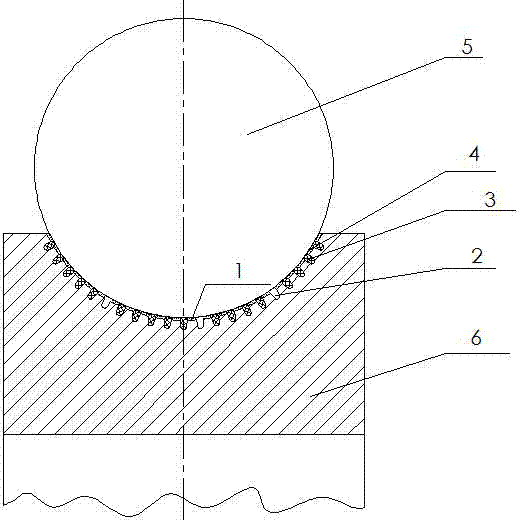

[0042] combine figure 1 , When the bearing is in motion, due to heat and friction, the solid lubricant 3 will continuously seep out and transfer to play the role of lubrication and friction reduction. The machining of the micro-cavity 11 or the micro-groove is realized by removing the material by the laser. Through the strengthening effect of the laser on the metal material, the strengthening of the bearing bearing area is realized. By reserving micro-cavities 11 or micro-grooves, the collection of lubricating oil (grease) and abrasive particles during operation is realized, and the adaptability to complex working conditions is improved. At the same time, laser micro-modeling and self-lubricating treatment can also be carried out on the raceway of the outer ring of the bearing according to the needs.

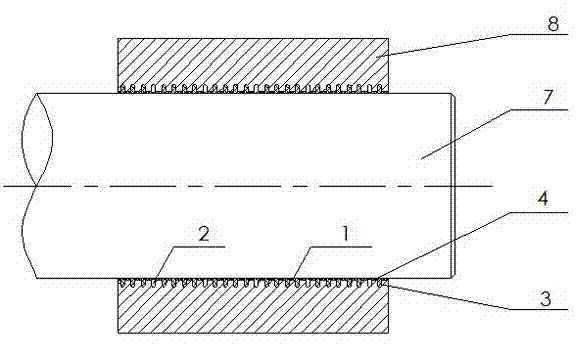

[0043] combine figure 2 , Since the shaft 7 and the sliding bearing sleeve 8 are always in a state of sliding friction, using solid lubrication treatment, the effect of redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com