Method for preparing deionized formamide

A technology for deionizing formamide and formamide, which is used in the fields of forensic genetics and molecular biology, and can solve problems such as reducing flow and production capacity, and increasing fluid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

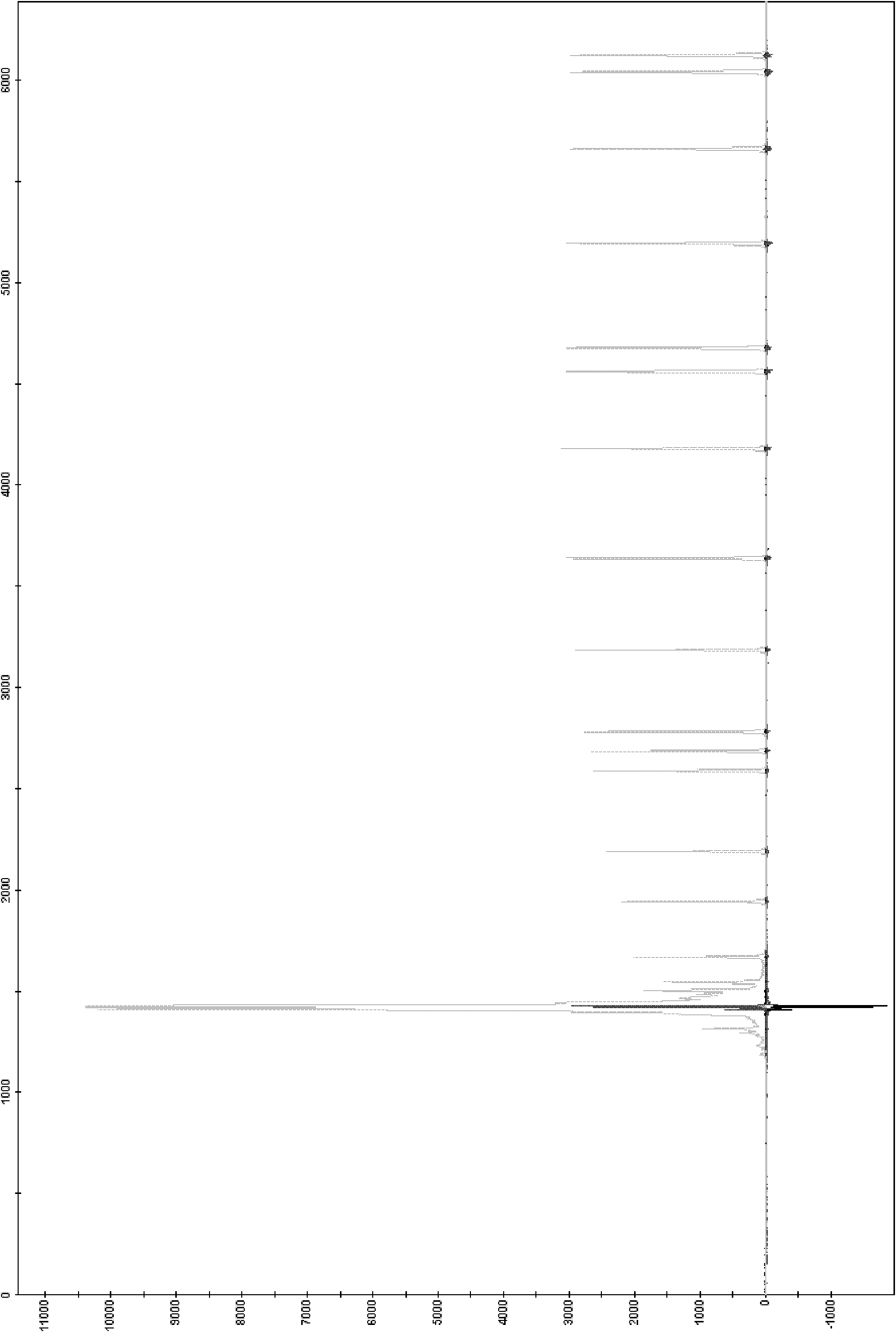

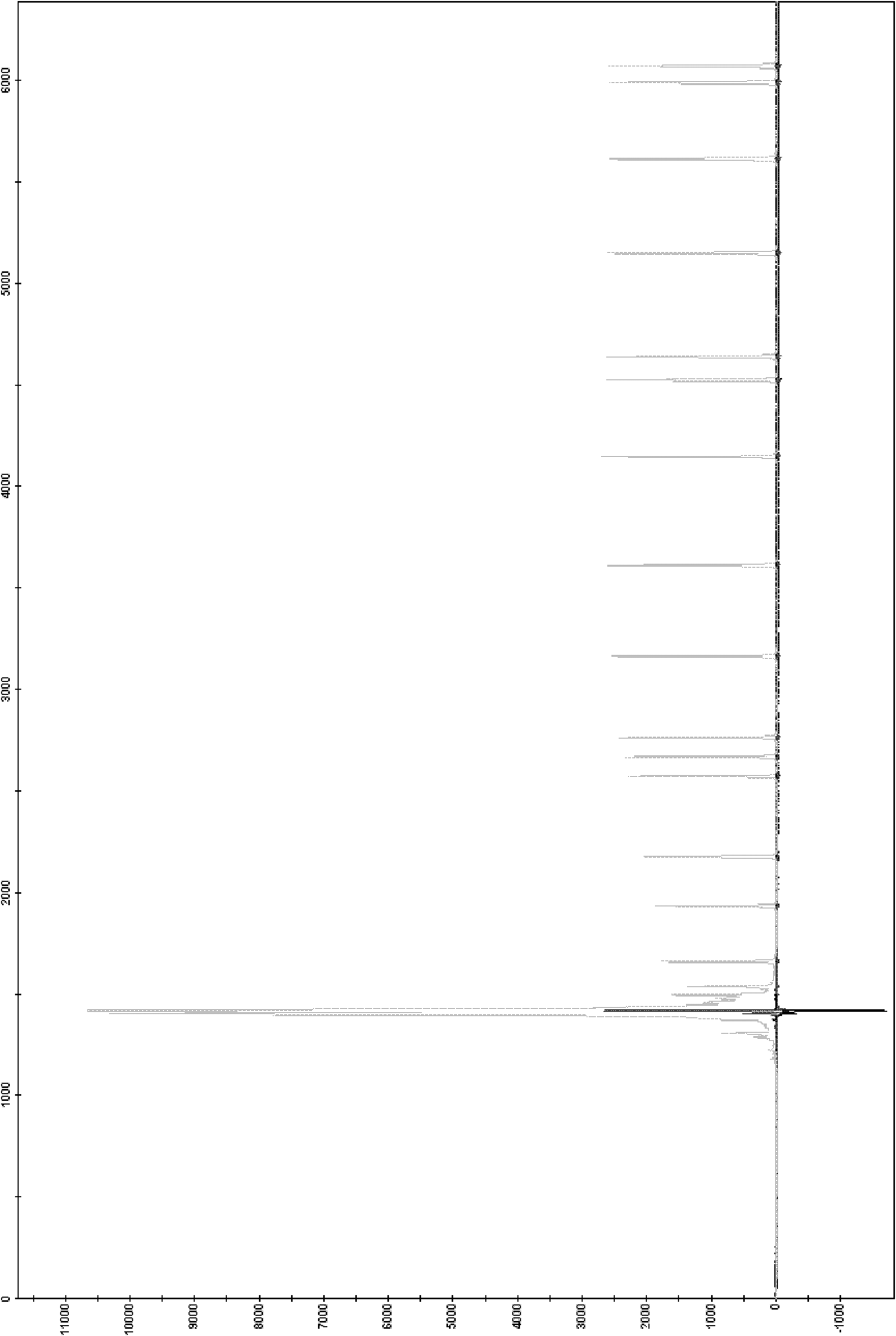

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of deionized formamide

[0031] (1) Take 100 ml of analytically pure (99.9% by mass) formamide (purchased from Fisher Company) and put it in a flask.

[0032] Weigh out 25 g of Bio-Rad AG501-X8 resin with 5% crosslinking.

[0033] The resin is subjected to freeze-dehydration treatment, that is, freeze-dehydration is carried out overnight, so that the water in the ion exchange resin is completely evaporated to dryness, and the particle size of the above-mentioned resin is 300-1180um.

[0034] (2) Mix the freeze-dehydrated resin in the above step (1) with the formamide in the flask, and gently shake for no more than 7 hours. In this embodiment, shake for 3 hours to fully contact the ion exchange resin with formamide.

[0035] (3) Filter the homogeneously mixed mixed solution in the above step (2) through a pre-cleaned Whatman#1 filter (the pore size of the filter is 0.22um), and collect the filtrate to obtain deionized formamide.

[0036] (...

Embodiment 2

[0037] Embodiment 2, the preparation of deionized formamide

[0038] (1) Take 100ml of analytically pure (99.9%) formamide (purchased from Amresco), put it in a 250ml flask, and check its pH value.

[0039] Weigh out 5 g of Bio-Rad MB-3 resin with a degree of crosslinking of 5%.

[0040] The resin was added to a flask containing formamide (that is, the ratio of formamide: ion exchange resin was 100ml: 5g), and a magnetic stirring bar (length 1.2cm) was added.

[0041] (2) Cover the flask in which the magnetic stirrer has been added in the above step (1) and start the magnetic stirrer for stirring, the stirring speed is 600rpm.

[0042] According to the pH value of the formamide detected in the above-mentioned steps (1), determine the stirring time: 1. if the pH of initial formamide is less than 7.0, the magnetic stirring time is 45 minutes; 2. if the pH of initial formamide is greater than 7.0, the magnetic stirring time is 60 points. So far, a stirred mixed solution is obt...

Embodiment 3

[0045] Embodiment 3, detection analysis

[0046] 1. Determination of the water content of the prepared deionized formamide sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com